Ventilating type simulation three-dimensional decorative film

A decorative film and air-permeable technology, applied in special decorative structures, decorative arts, etc., can solve the problems that the decorative film cannot breathe by itself, the life of the decorative film is short, and the pattern is not realistic enough, so as to enhance the three-dimensional effect, reduce the cost, shorten the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

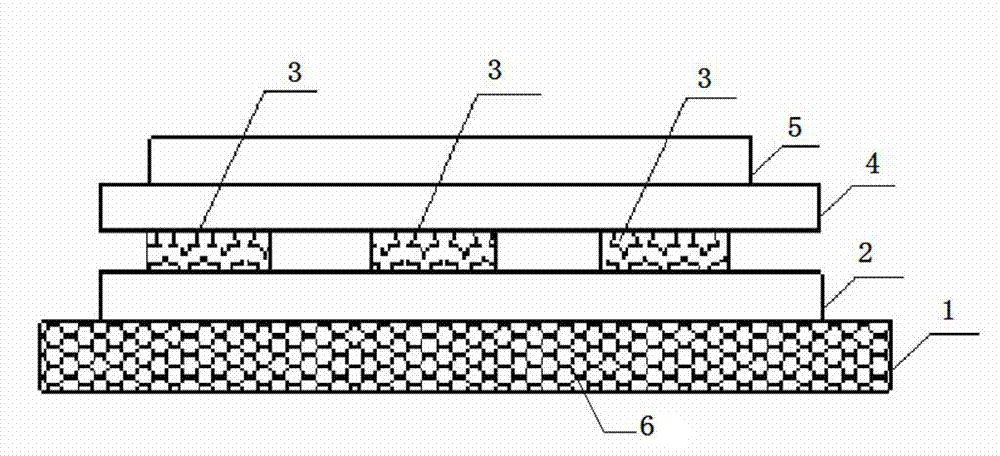

[0013] As shown in the figure, a breathable simulated three-dimensional decorative film is characterized in that it includes: PP substrate 1, spot color layer 2, bright coating 3, pattern layer 4, matte coating 5, the spot color Layer 2 is printed on the upper surface of the PP substrate 1, the bright coating 3 is printed on the upper surface of the spot color layer 2, and the pattern layer 4 is printed on the upper surface of the bright coating 3, so The matte coating 5 is printed on the upper surface of the pattern layer 4 .

[0014] After the printing is completed, micropores 6 are provided on the PP base material 1 to allow the decorative film to breathe on its own, to prevent mildew of the decorative film caused by moisture in the walls and indoors, and to shorten its service life. Through the mirror reflection of the bright coating 3, the pattern layer 4. There is a difference in glossiness, which enhances the three-dimensional effect. Due to its own thickness, the matte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com