Two-dimensional ultrathin titania-modified polyester nano composite brush bristles and preparation method thereof

A modified polyester and nanocomposite technology, applied in the direction of single-component polyester rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve the difficulty of high-performance materials, cost money and energy, and limit polyester products. Scope of application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a two-dimensional ultra-thin titanium dioxide modified polyester nanocomposite brush filament, comprising:

[0038] Step 1: Preparation of two-dimensional ultrathin nano-TiO 2

[0039] Under the protection of nitrogen, add titanium tetrachloride to ethylene glycol, heat to reflux, and then add water to react. After the reaction, cool down to room temperature, centrifuge and wash to obtain two-dimensional ultra-thin nano-TiO 2 ; The reaction time is preferably 30min-5h; more preferably 2-4h, the volume ratio of ethylene glycol and titanium tetrachloride is preferably (5-100): 1, more preferably (5-6) : 1, the volume ratio of titanium tetrachloride to water is preferably (1-4): 1, more preferably (1-1.25): 1; the ethylene glycol is used as a directing agent;

[0040] Step 2: Modified two-dimensional ultrathin nano-TiO 2

[0041] Surfactant and two-dimensional ultrathin nano-TiO 2 reaction to obtain modified t...

Embodiment 1

[0048] Under the protection of nitrogen, add 0.5L titanium tetrachloride to 3.0L ethylene glycol, heat to reflux, add 0.5L water to react with titanium tetrachloride, react for 2.0h, cool down to room temperature, and perform centrifugation and washing. Two-dimensional ultrathin nano-TiO 2 .

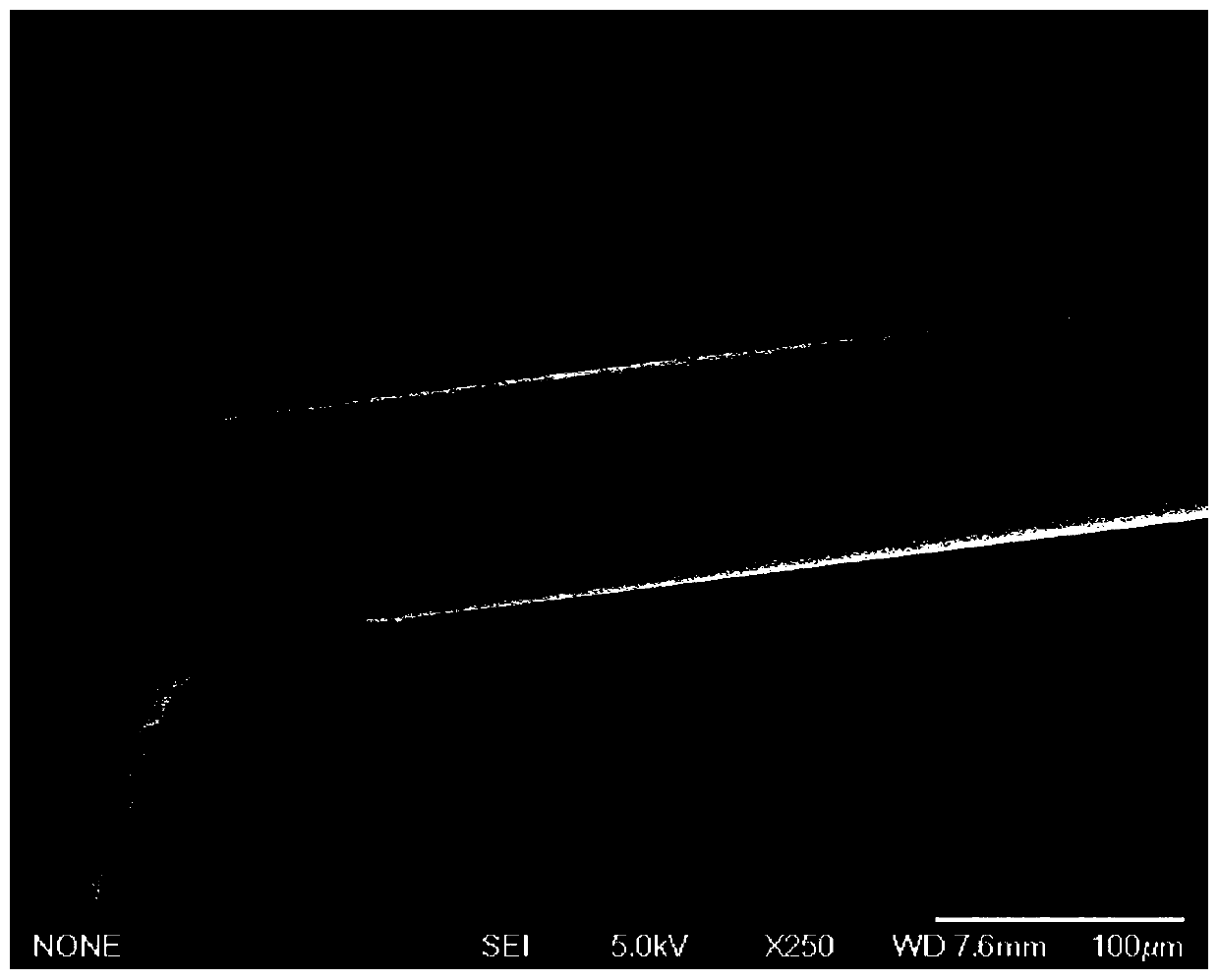

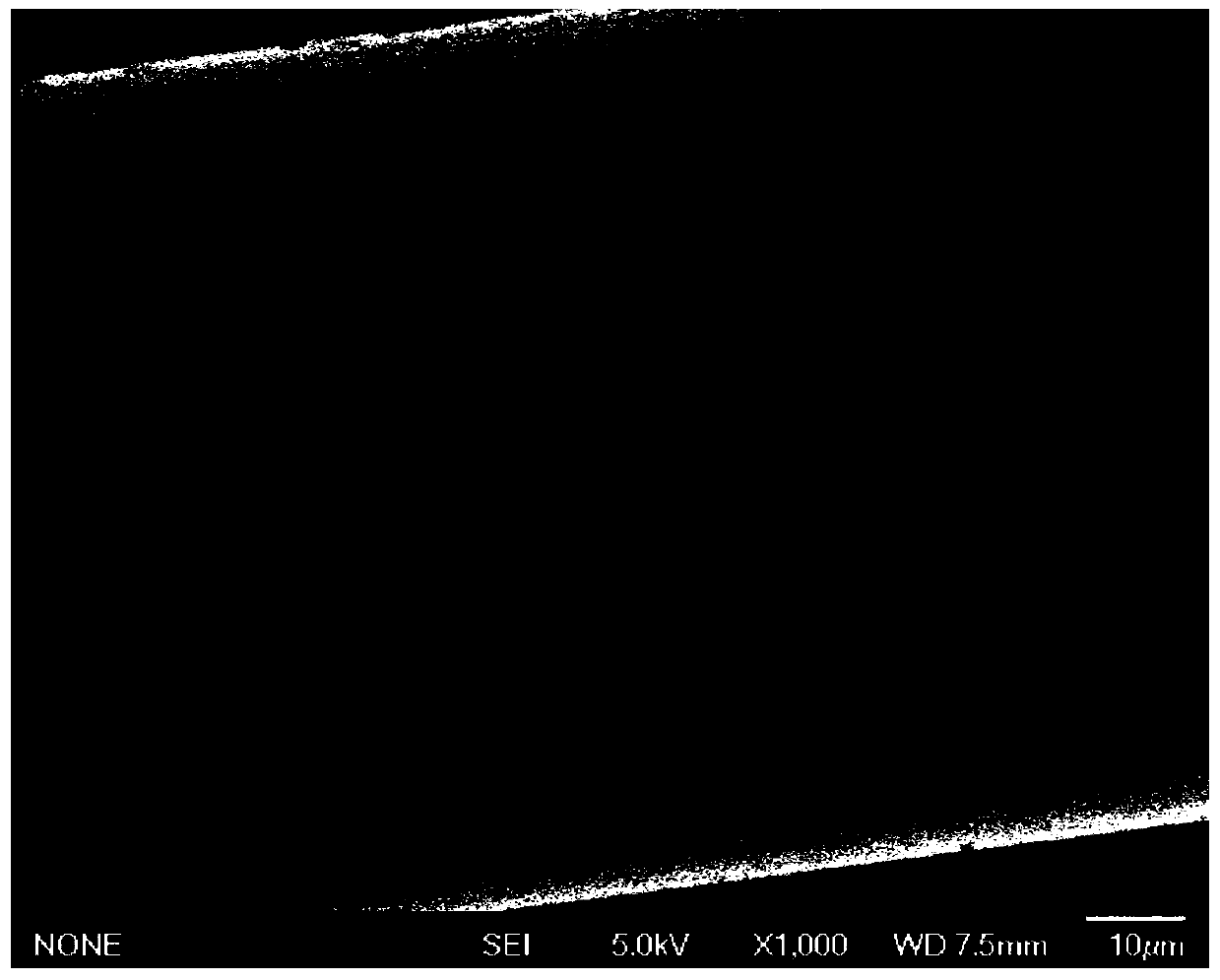

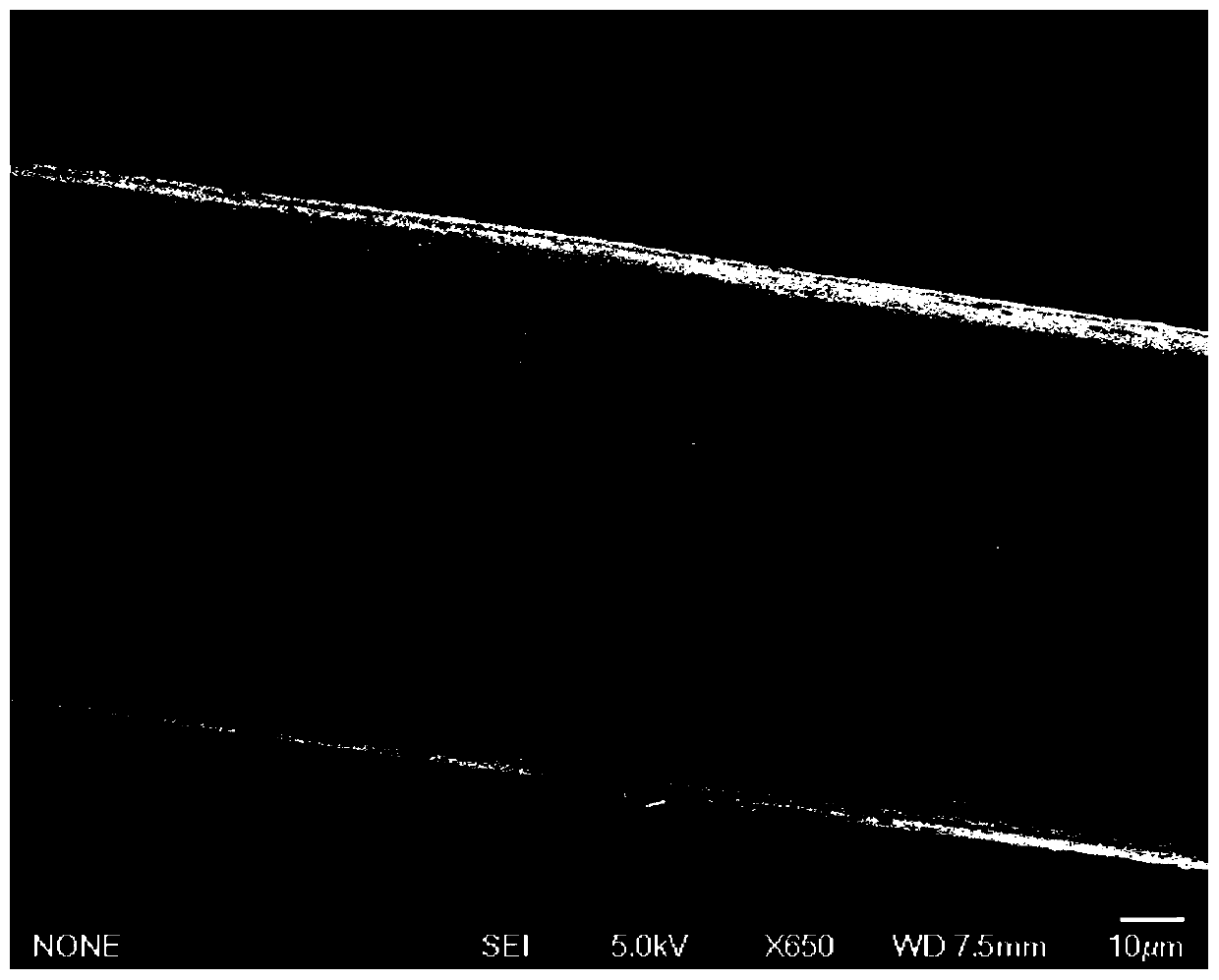

[0049] two-dimensional ultrathin nano-TiO 2 Reversely disperse in a mixed solution of water and ethanol (the volume ratio of water and ethanol is 9:1), super-disperse for 50min, then add surfactant KH550, react at 70°C for 4h, after cooling, centrifuge at 5000r / min, and dry at 100°C Overnight, the addition of the surfactant is two-dimensional ultra-thin nano-TiO 2 5% of the mass; modified two-dimensional ultra-thin nano-TiO 2 -M (thickness 20nm, aspect ratio 15).

[0050] PBT material and modified two-dimensional ultrathin nanosheet TiO 2 -M drying, the drying temperature is 110 ° C, and the drying time is 6 hours, which can improve the spinnability of the fiber; then the PBT materi...

Embodiment 2

[0054] Under the protection of nitrogen, add 0.5L titanium tetrachloride to 3.0L ethylene glycol, heat to reflux, add 0.5L water to react with titanium tetrachloride, react for 2.0h, cool down to room temperature, and perform centrifugation and washing. Two-dimensional ultrathin nano-TiO 2 .

[0055] two-dimensional ultrathin nano-TiO 2 Reversely disperse in a mixed solution of water and ethanol (the volume ratio of water and ethanol is 9:1), super-disperse for 50min, then add surfactant KH550, react at 70°C for 4h, after cooling, centrifuge at 5000r / min, and dry at 100°C Overnight, the addition of the surfactant is two-dimensional ultra-thin nano-TiO 2 5% of the mass; modified two-dimensional ultra-thin nano-TiO 2 -M (thickness 20nm, aspect ratio 15).

[0056] PBT material and modified two-dimensional ultrathin nano-TiO 2 -M drying, the drying temperature is 110 ° C, and the drying time is 6 hours, which can improve the spinnability of the fiber; then the PBT material in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com