Automated production line and automated production method of light-weight wall material

A technology for automated production lines and wall materials, applied in chemical instruments and methods, ceramic molding workshops, liquid ingredient supply devices, etc., can solve problems such as no profit in factories, poor promotion of products, and low labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

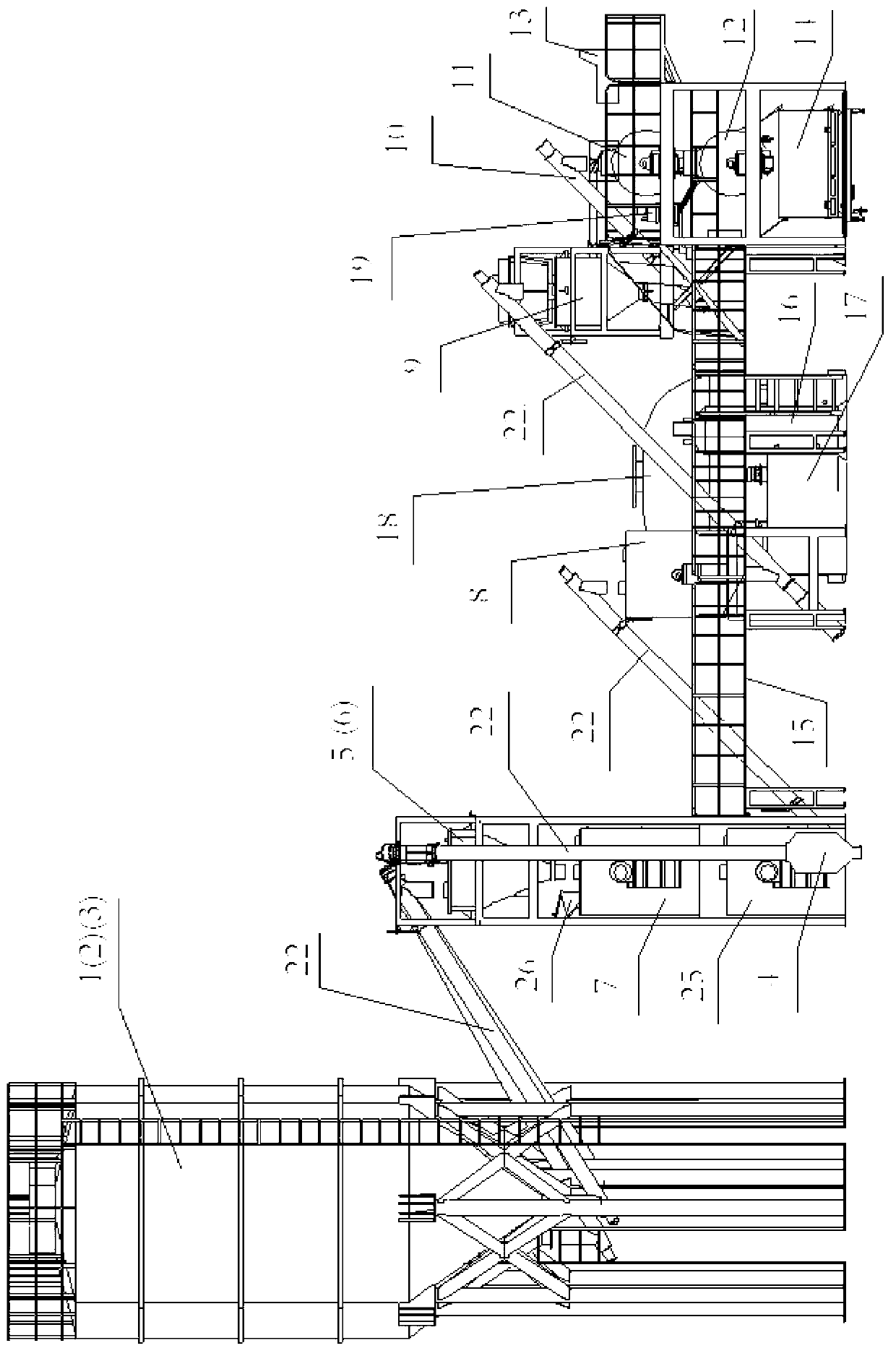

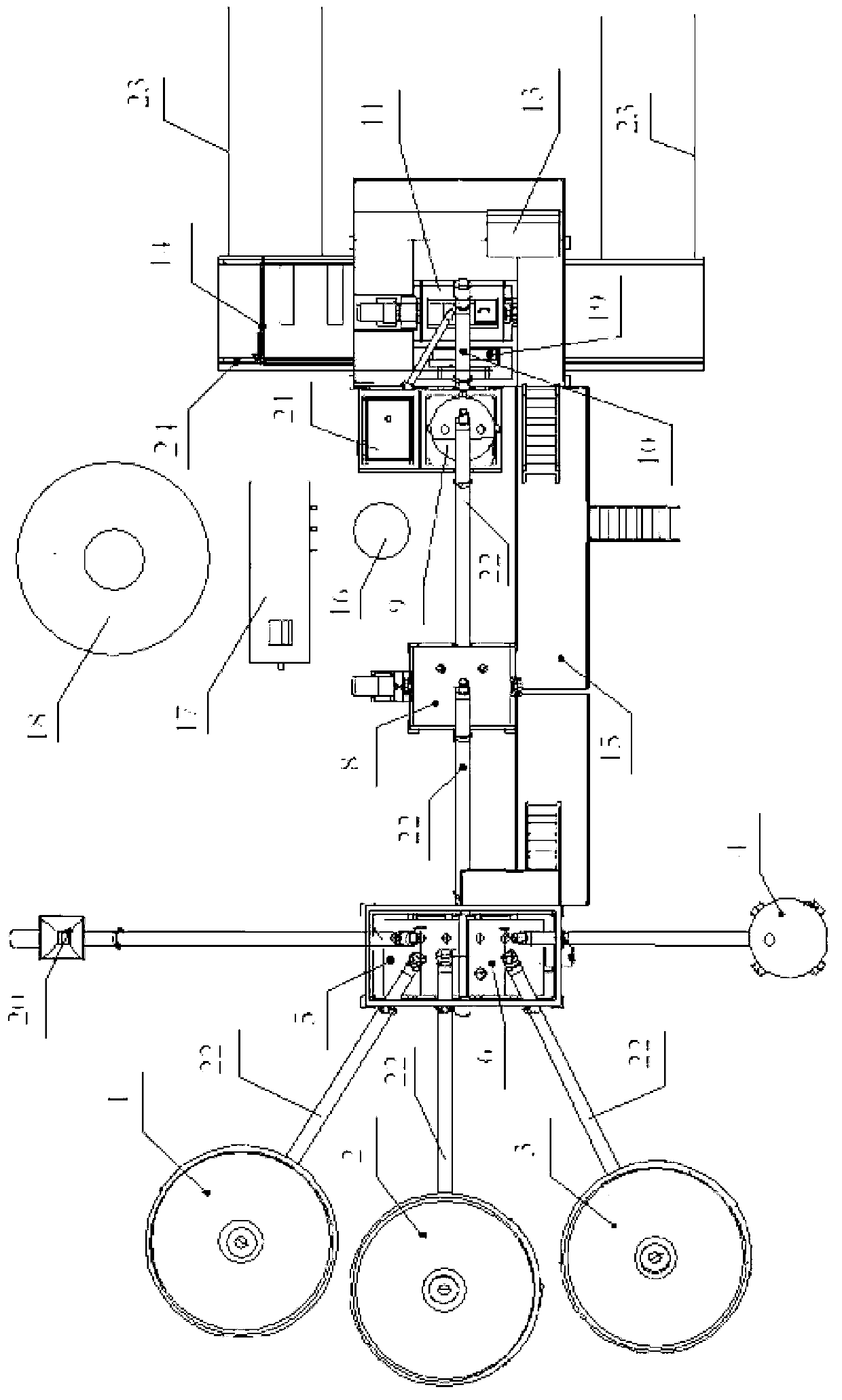

[0050] Such as figure 1 , 2 As shown, the automatic production line of light wall materials includes the quantitative supply system of raw materials, compound mixing system, constant temperature water supply system, foaming agent supply system, stirring reaction system, electrical control system, mold box conveying device and equipment connection platform 15.

[0051] The raw material quantitative supply system includes cement storage bin 1, mineral powder storage bin 2, fly ash storage bin 3, polymer storage bin 4, automatic conveying equipment 22, recycled material automatic feeder 20, main material quantitative bin 5 and Auxiliary material quantitative warehouse 6, one electronic metering scale is set in the main material quantitative warehouse 5, and electronic metering scale two is arranged in the auxiliary material quantitative warehouse 6; the main material quantitative warehouse 5 and the auxiliary material quantitative warehouse 6 are arranged side by side; The ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com