Overwater driving type underwater water impeller

A drive-type, flow pusher technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that sewage treatment plants cannot stop water inflow, damage, cable wire grinding, etc. problems such as breakage, etc., to achieve the effect of good sewage treatment effect, lower production cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

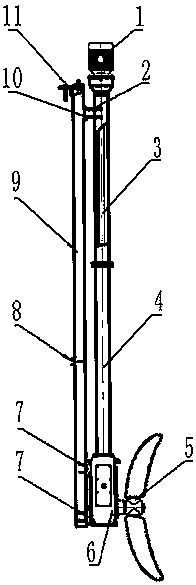

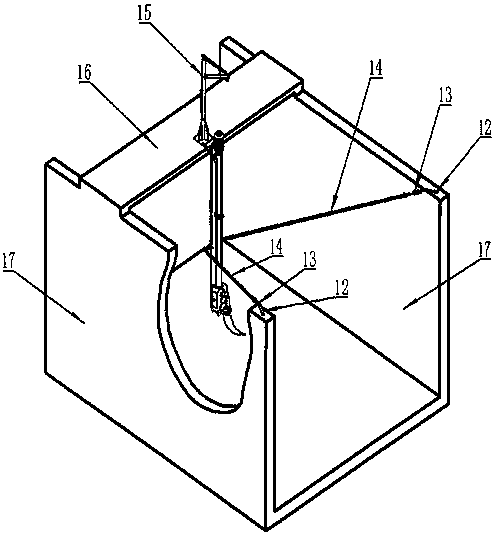

[0008] This technical solution is mainly composed of motor, support cylinder, transmission vertical shaft, impeller, reversing reduction box and support rod and other components. The specific implementation is as follows: figure 1 As shown, the motor 1 is fixed on the upper end of the support cylinder 4, the length of the support cylinder is about 3500cm, and the end of the support cylinder is fixed underwater on the reversing reduction box 6, and the inner cavity of the support cylinder is equipped with Transmission vertical shaft 3, one end of the rotating vertical shaft is connected to the output shaft of the motor 1, and the other end is connected to the input shaft on the potential underwater reversing reduction box, in order to make the transmission vertical shaft in the inner cavity of the supporting cylinder more stable when working , a support rod 9 is installed side by side adjacent to the support cylinder, the two are connected through the support cylinder fixing bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com