Cocooning frame grooving machine achieving dust removal and sound insulation conveniently

A technology for slotting machines and cobwebs, which is applied to slotting machines, mortising machines, mechanical equipment, etc. It can solve the problems of no oil storage tank, no sound insulation warehouse and sound-absorbing cotton, and inconvenient installation and removal of sound-absorbing cotton. , to achieve the effect of easy installation and disassembly, scientific and reasonable structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

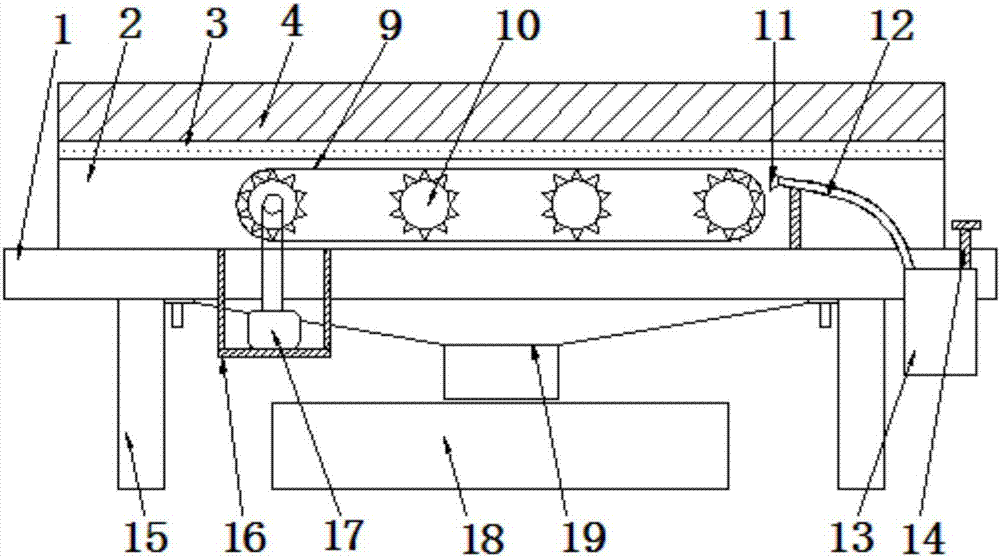

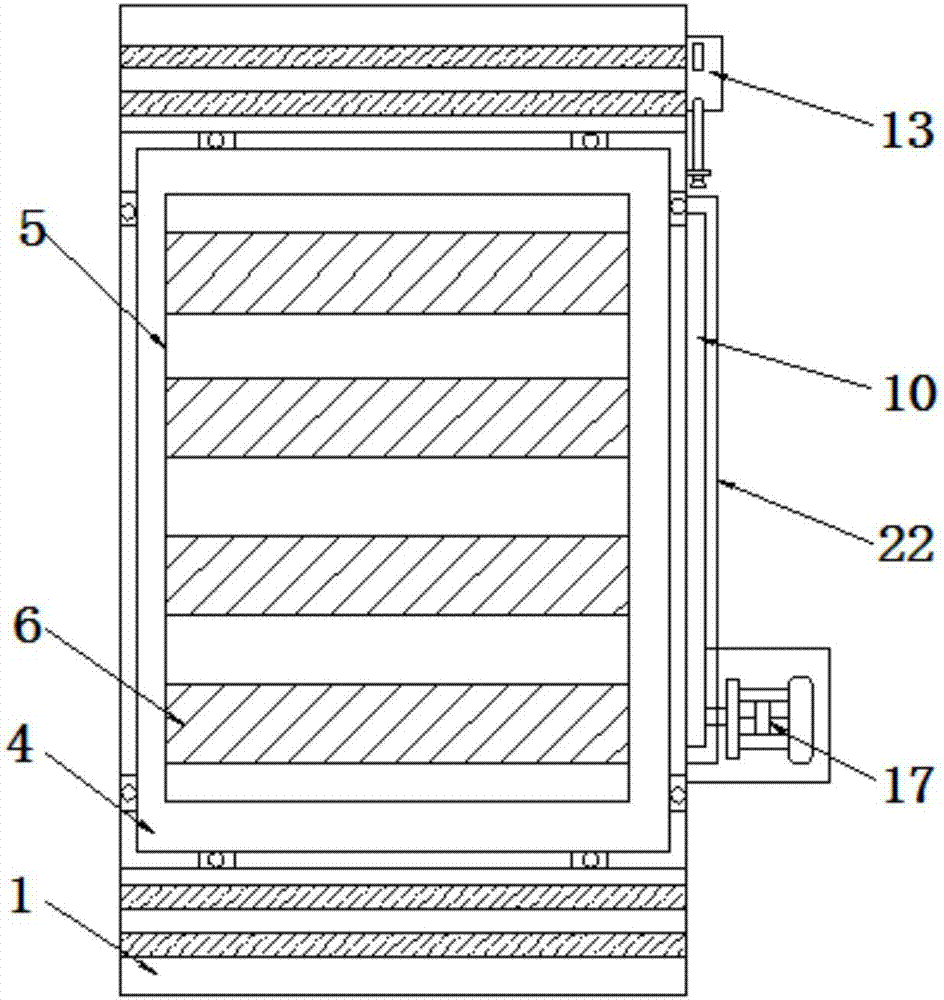

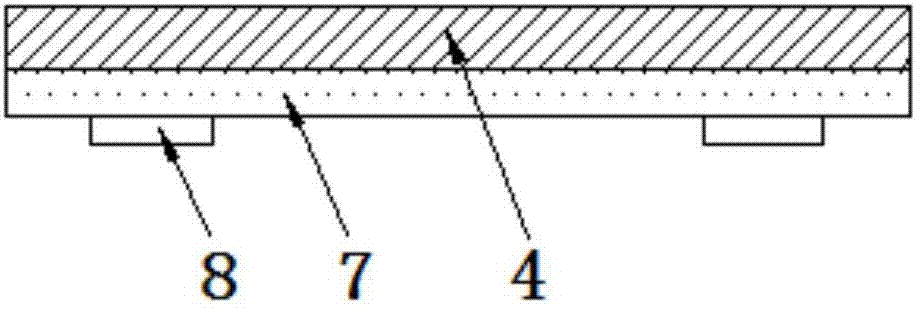

[0019] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a silkworm cotter slotting machine that is convenient for dust removal and sound insulation, including a workbench 1, a baffle plate 2, a rubber pad 3, a sound insulation chamber 4, a viewing window 5, a roller 6, and a sound-absorbing Cotton 7, magnet 8, pulley 9, sprocket 10, nozzle 11, hose 12, oil storage tank 13, pressing rod 14, support leg 15, motor support frame 16, motor 17, dust collection tank 18, funnel 19, partition Plate 20, lower pressing plate 21 and protective cover 22, a baffle 2 is installed on the top of the workbench 1, a soundproof warehouse 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com