Novel distributing machine

A distributing machine, a new type of technology, applied in the direction of conveyor objects, transportation and packaging, supporting frames, etc., can solve the problems of inability to stretch freely, high operating costs, and inability to be fast and effective, and achieve the goal of improving work efficiency and reducing operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

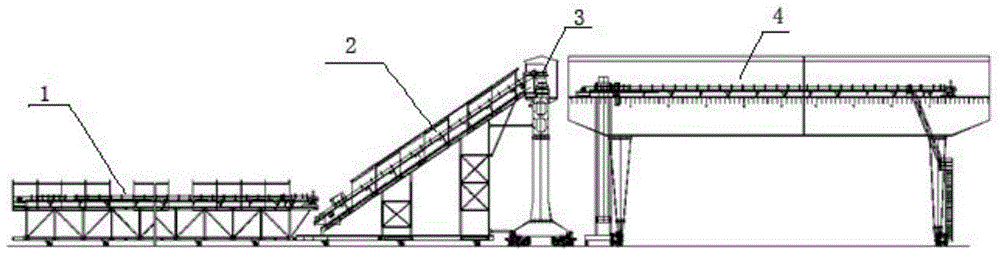

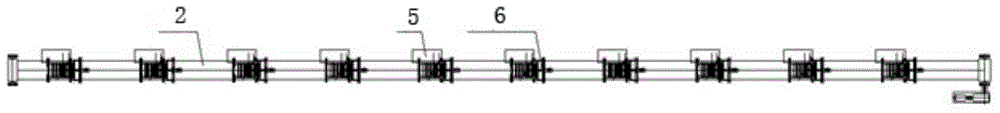

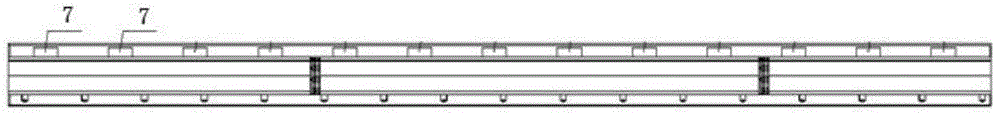

[0017] The present invention is further set forth below through the accompanying drawings of the description;

[0018] according to Figure 1 to Figure 5 As shown, a new type of distributing machine includes a horizontal conveyor belt 1 and a feeding conveyor belt 2 connected to the distributing machine 3, and a plurality of unloaders 6 are installed on the conveyor belt 2 carrying the gantry beam mechanism 4. The device 6 separates the material into the material box 5. The material box 5 is arranged on the upper part of the walking platform of the distributing machine 3. There is a leak at the bottom of the material box 5. The corresponding part of the walking platform 10 and the material box 5 is provided with a reserved opening 7. The material The material pile 8 is formed through the leakage opening and the reserved opening 7, the unloader 6 is a plow unloader 6, and the load-bearing gantry beam mechanism 4 includes a main beam 11, supporting legs 12, lower beams 14, ladde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com