Unit-type flexo printing machine connecting EB irradiation real-time curing type compound machine

A flexographic printing machine, unit type technology, applied in printing presses, rotary printing presses, rotary printing presses, etc., can solve the problems of low machine start-up speed, low running speed of in-line units, and high exhaust gas emissions, and achieve machine operation. The effect of increased speed, compact structure of the whole machine, and environmental protection of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

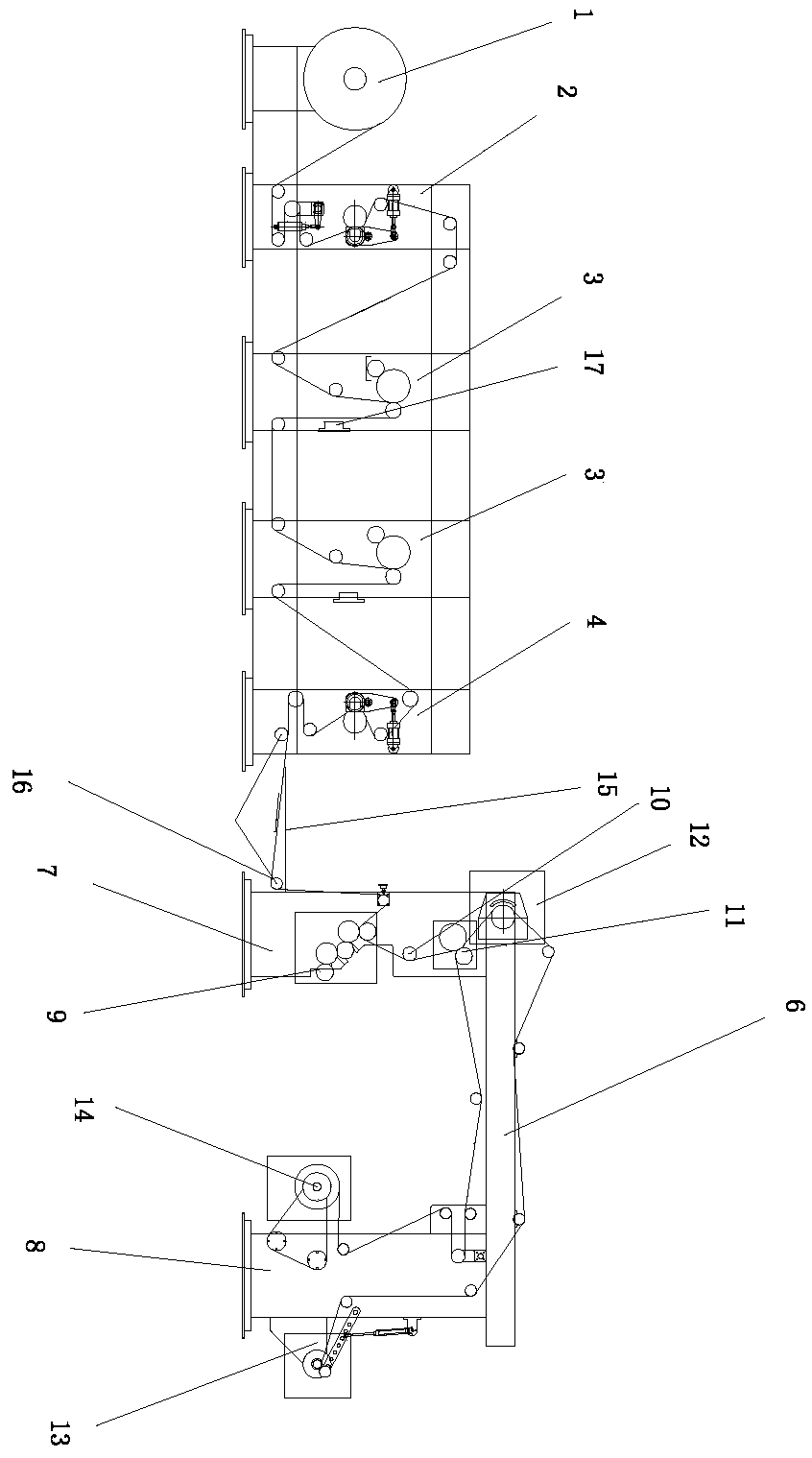

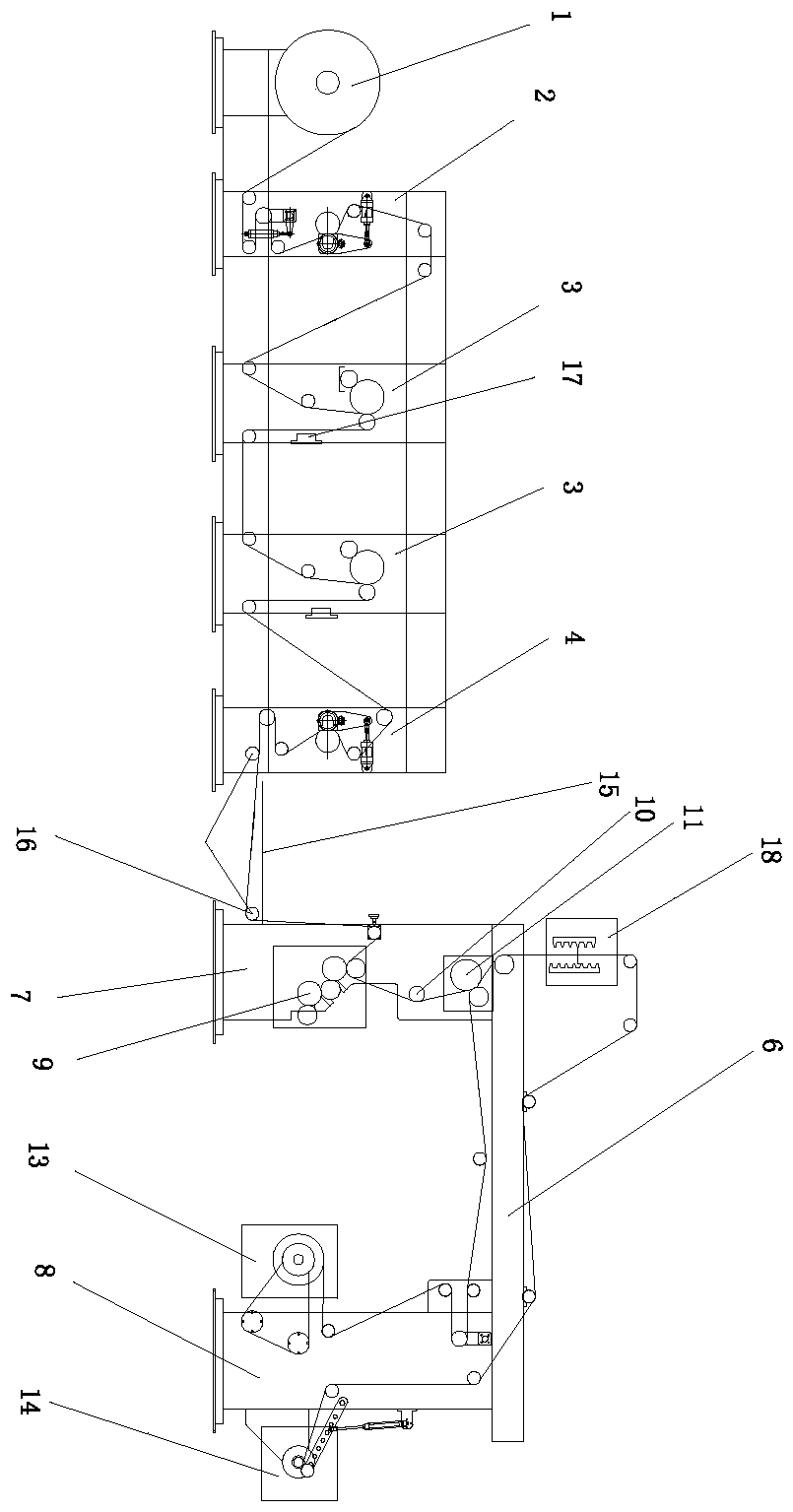

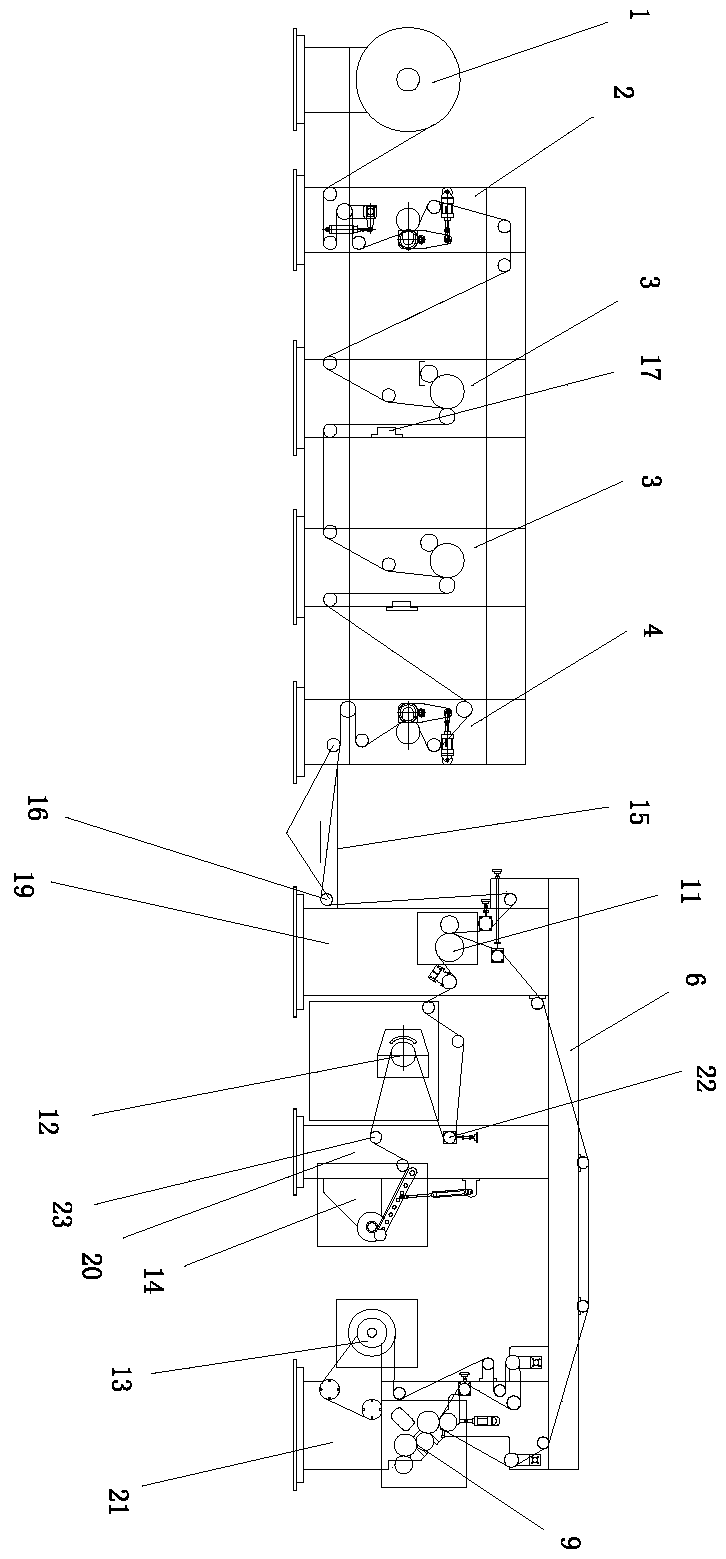

[0017] figure 1 It is a structural schematic diagram of the first form of the present invention, including a printing unwinding unit 1, a printing unwinding traction unit 2, two flexographic printing color groups 3, a printing winding traction unit 4 and a composite Curing device, described composite curing device comprises connecting longitudinal beam 6, is provided with coating composite frame 7 and winding frame 8 from left to right at connecting longitudinal beam 6 lower ends, on coating composite frame 7 from bottom to top The coating unit 9, the compound tension roller 10, the compound unit 11 and the focusing EB generator 12 are arranged in sequence on the top, and the second unwinding unit 13 and the winding unit 14 are arranged on the left and right sides of the winding and unwinding frame 8, A walking platform 15 is provided between the printing rewinding traction unit 4 and the composite curing device, and an in-line film-moving roller 16 is provided below the walki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com