Inclined plane anvil forging connecting rod transition conical face and transition conical face machining method thereof

A transition cone and connecting rod technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of high processing cost, many forging processes, large processing allowance, etc., and achieve short machining cycle , High material utilization rate, good effect of metal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

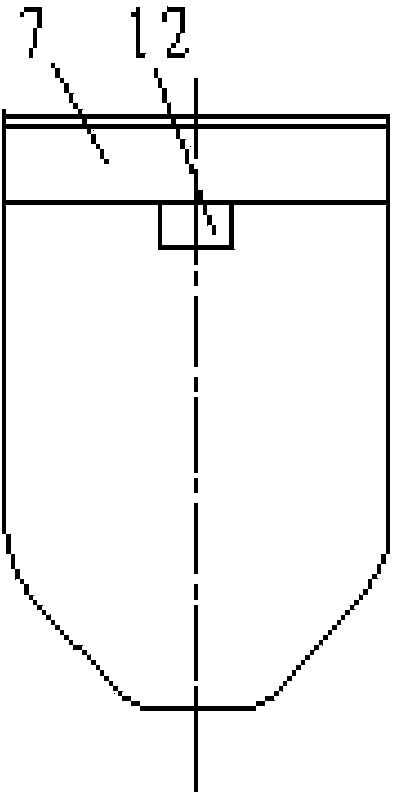

[0022] The inclined plane anvil of the present invention is made up of upper anvil part and lower anvil part, and upper anvil part is made of upper anvil and upper anvil seat, and lower anvil part is made of lower anvil 3 and lower anvil seat 4, and the bottom, upper part shape of upper and lower anvil Consistent with the shape of the conical surface of the connecting rod (see figure 2 , 4 ).

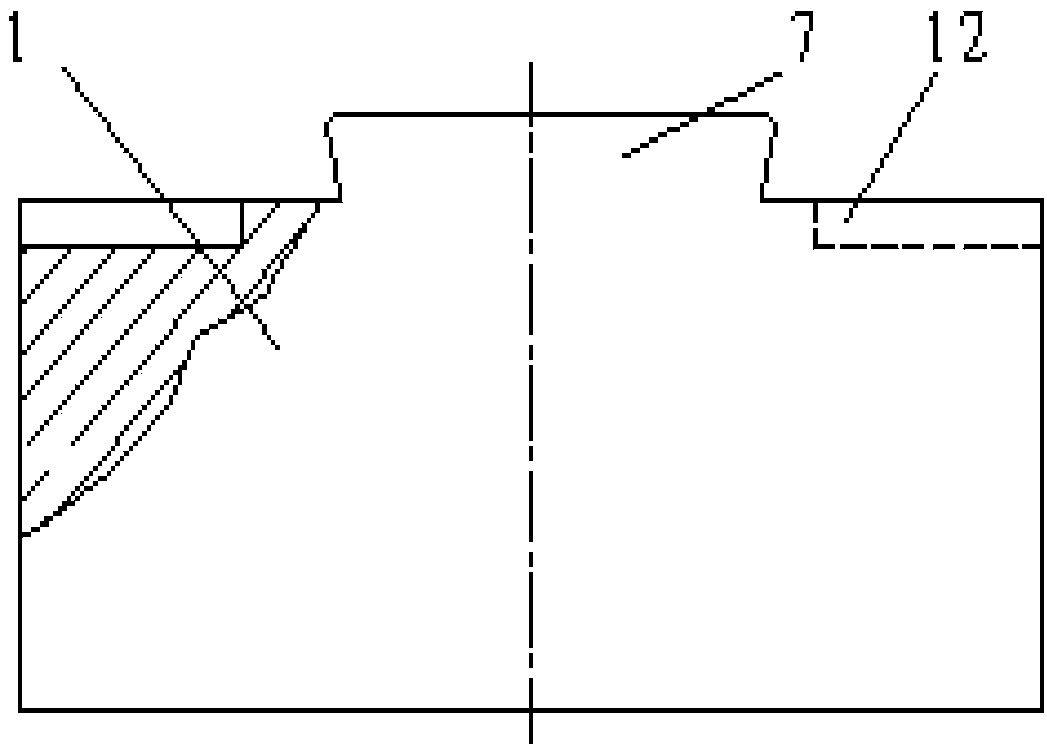

[0023] refer to figure 1 , 2 , 5, the upper anvil 1 of the upper anvil part ( figure 1 ) of the dovetail 7 snap into the dovetail groove 8 of the anvil 2, and the two are fixed as one by the tapered iron wedge 13 inserted, and the flat key 14 inserted into the anvil keyway 12 and the anvil keyway 11.

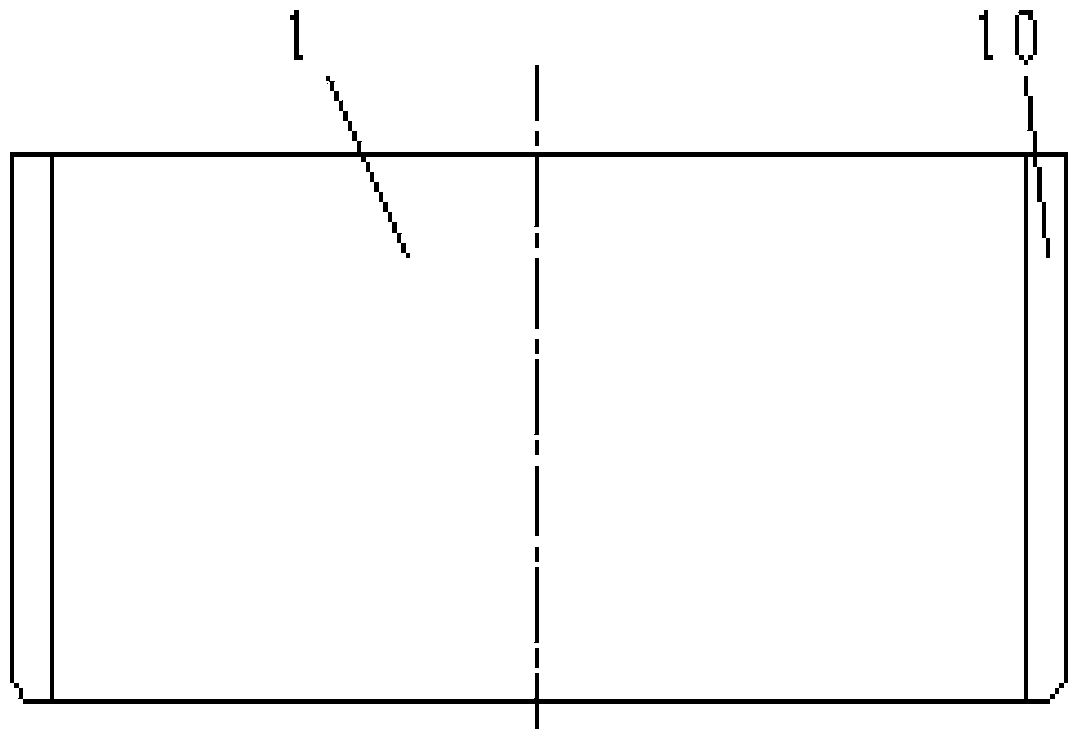

[0024] refer to image 3 , 4 , 6, the side protruding narrow side 10 of the lower anvil 3 of the lower anvil part is placed in the keyway 9 of the lower anvil.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com