Glazing compound raw material analysis process

A technology for glass sealant and raw materials, which is applied in the direction of chemical analysis by titration method, can solve the problems of reducing the quality of glass sealant, inconvenient production and analysis, and poor sealing of glass sealant, and achieves convenient and economical production and analysis. The effect of saving manpower and material resources and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

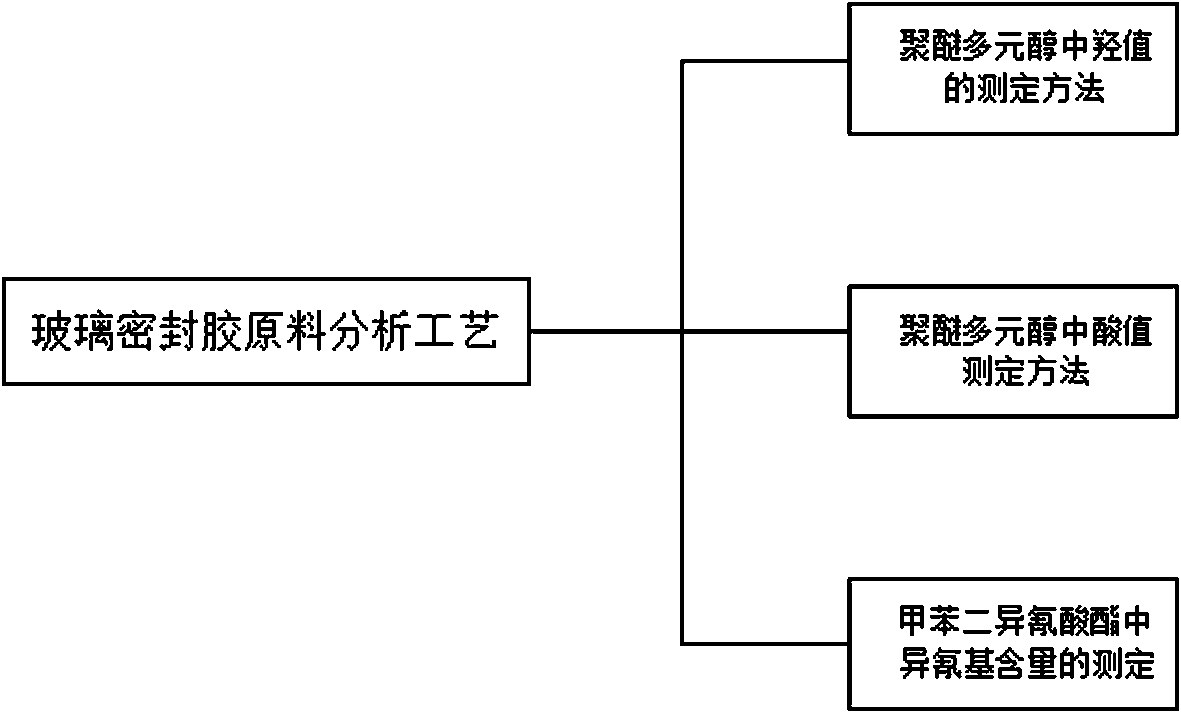

[0030] Example: such as figure 1 As shown, the present invention provides a technical solution, a glass sealant raw material analysis process, including a method for determining the hydroxyl value in polyether polyols, comprising the following steps:

[0031] S1. Weigh 116g of phthalic anhydride into a 1L brown bottle, add 700mL of pyridine and shake vigorously until it dissolves, add 16g of imidazole and shake carefully until dissolved. The solution should be left standing overnight before use to avoid long-term exposure to absorb moisture in the air;

[0032] S2. When the color becomes darker, the reagent should be discarded. In blank titration, 25ml of this reagent should consume 95ml to 100ml of 0.5mol / L sodium hydroxide standard titration solution.

[0033] According to the above technical scheme, the assay method includes the following features:

[0034] (1) The prepared solution must be pasted in a brown bottle and kept away for 24 hours before use. This solution must...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com