Novel non-asphalt-based self-adhesive waterproofing coiled material and preparation method thereof

A self-adhesive waterproof membrane, non-bitumen-based technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive types, etc., can solve the problems of high raw material and processing costs, and achieve a dense and gap-free overlapping effect. The effect of reducing production tension and strong adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

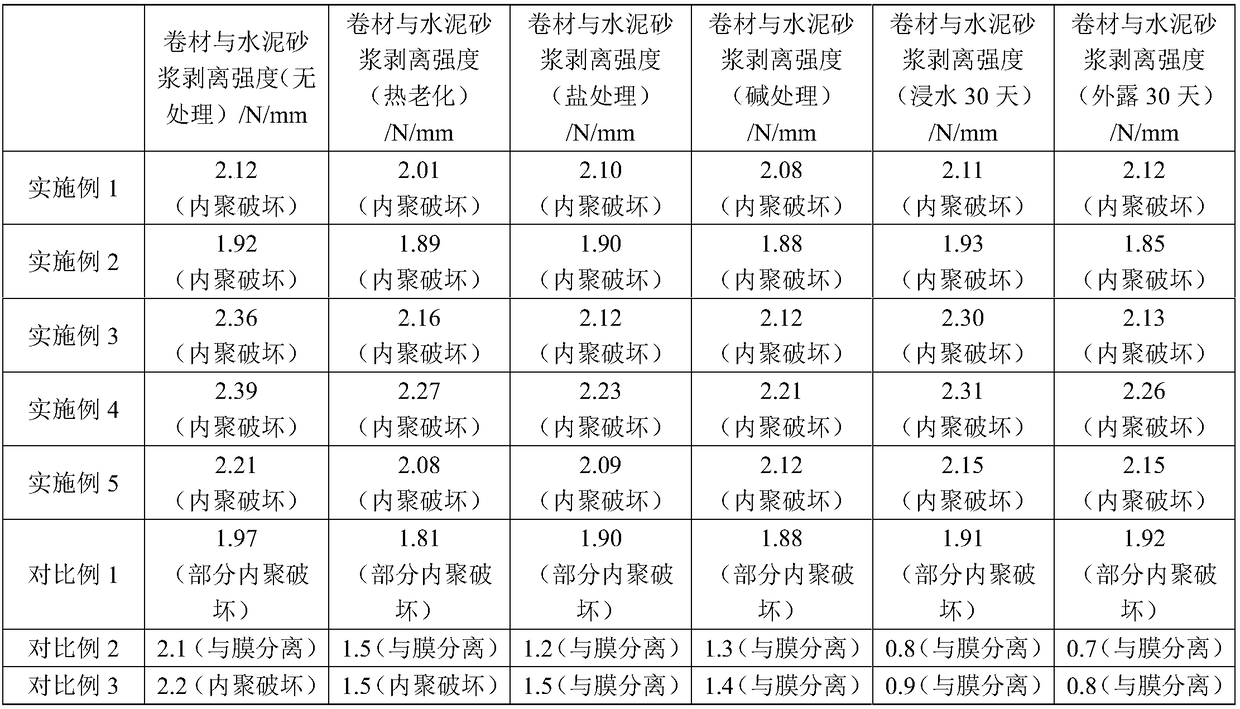

Examples

Embodiment 1

[0042]This embodiment provides a new type of non-bitumen-based self-adhesive waterproof membrane, which includes a main base material, a non-bitumen self-adhesive adhesive covering the main base material, and an isolation film. The non-bituminous self-adhesive compound is composed of the following raw materials in weight percentage: 10% of C5 / C9 copolymer resin, 14% of polyisobutylene, 25% of naphthenic rubber oil, 12% of SIS rubber, 14% of styrene-butadiene rubber, and 16.5% of filler %, pigments 2.5%, additives 6%.

[0043] Among them, C5 / C9 copolymerized petroleum resin is a hydrogenated C5 / C9 copolymerized petroleum resin with a softening point of 90-110°C and a chroma of less than No. 5; polyisobutylene is polyisobutylene with a molecular weight of about 1000-5000; SIS rubber is isoprene SIS rubber with an olefin content of more than 80%; styrene-butadiene rubber is a styrene-butadiene solid powder rubber with a rubber content of more than 80% and a moisture content of le...

Embodiment 2

[0057] This embodiment provides a new type of non-bitumen-based self-adhesive waterproof membrane, which includes a main base material, a non-bitumen self-adhesive adhesive covering the main base material, and an isolation film. The non-bituminous self-adhesive rubber material is composed of the following raw materials in weight percentage: 25% of C5 / C9 copolymer resin, 3% of polyisobutylene, 25% of naphthenic rubber oil, 3% of SIS rubber, 4% of styrene-butadiene rubber, and 35% of filler %, pigment 0.5%, additive 4.5%.

[0058] Among them, C5 / C9 copolymerized petroleum resin is a hydrogenated C5 / C9 copolymerized petroleum resin with a softening point of 90-110°C and a chroma of less than No. 5; polyisobutylene is polyisobutylene with a molecular weight of about 1000-5000; SIS rubber is isoprene SIS rubber with an olefin content of more than 80%; styrene-butadiene rubber is a styrene-butadiene solid powder rubber with a rubber content of more than 80% and a moisture content of...

Embodiment 3

[0062] This embodiment provides a new type of non-bitumen-based self-adhesive waterproof membrane, which includes a main base material, a non-bitumen self-adhesive adhesive covering the main base material, and an isolation film. The non-bituminous self-adhesive rubber material is composed of the following raw materials in weight percentage: 15% of C5 / C9 copolymer resin, 12% of polyisobutylene, 22% of naphthenic rubber oil, 6% of SIS rubber, 10% of styrene-butadiene rubber, and 28% of filler %, pigments 2%, additives 5%.

[0063] Among them, C5 / C9 copolymerized petroleum resin is a hydrogenated C5 / C9 copolymerized petroleum resin with a softening point of 90-110°C and a chroma of less than No. 5; polyisobutylene is polyisobutylene with a molecular weight of about 1000-5000; SIS rubber is isoprene SIS rubber with an olefin content of more than 80%; styrene-butadiene rubber is a styrene-butadiene solid powder rubber with a rubber content of more than 80% and a moisture content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com