Machine and method for filling and weighing capsules

A capsule, machine technology, applied in the direction of capsule delivery, application, household components, etc., can solve the problem of not being able to take out the capsule and then insert it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

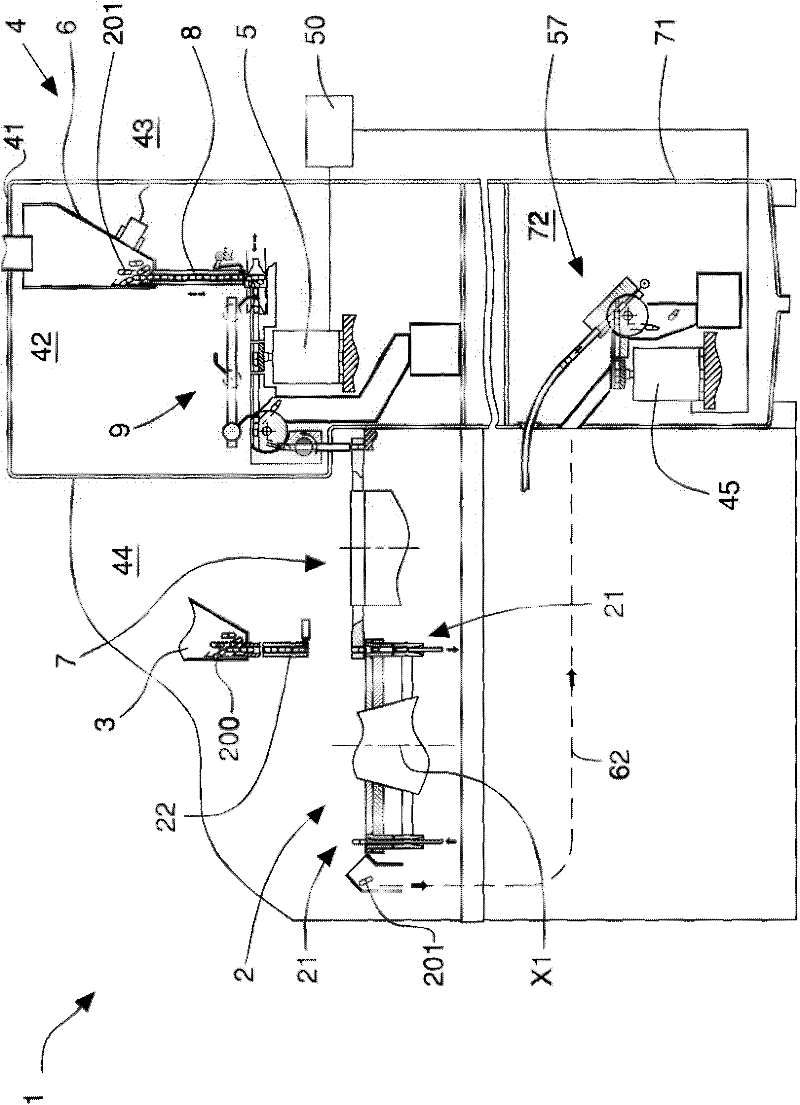

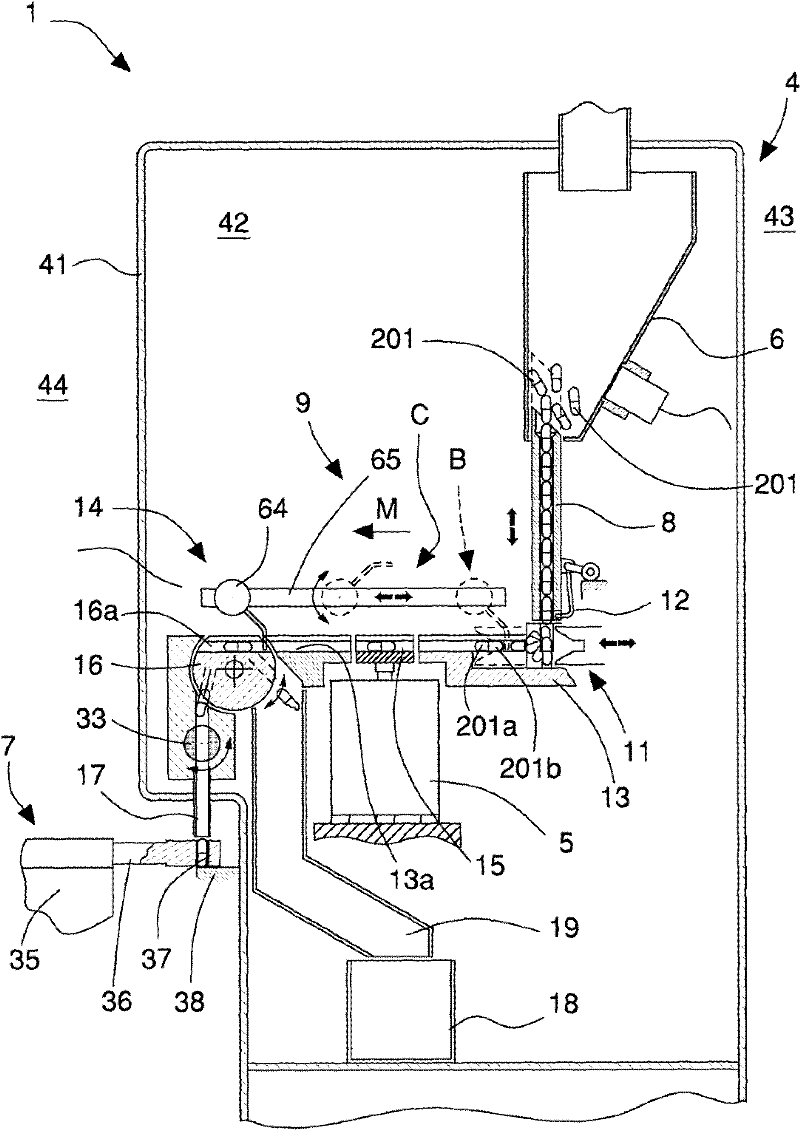

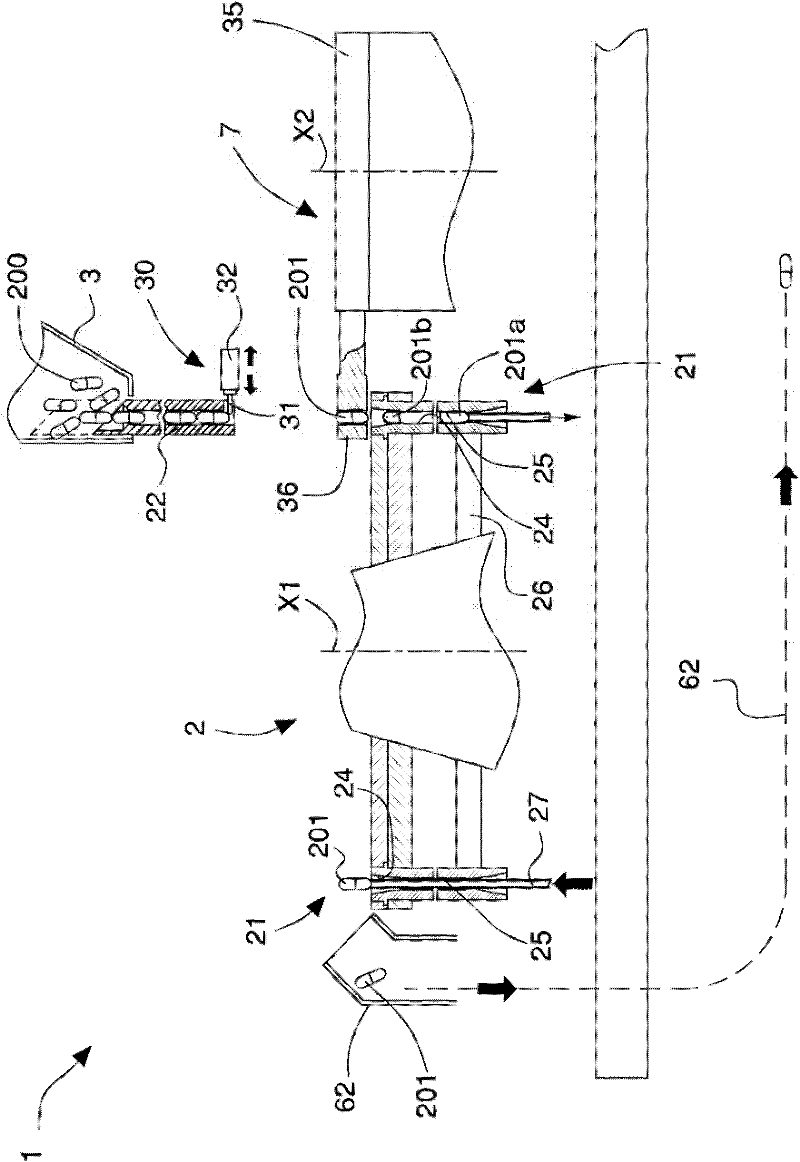

[0047] refer to Figures 1 to 7 , which shows a filling machine 1 for dosing a product (for example in powder, liquid or granular form) inside a capsule 200 or similar element, especially a hard gelatin capsule.

[0048] The machine 1 is provided with a turret arrangement 2 of known type and not shown in detail in the figures, comprising a single operating turret rotatable about a vertical axis of rotation X1, and the machine 1 comprising a plurality of operating stations 21 , each operating station is suitable for processing, ie performing a series of operations on, empty capsules 200 drawn from the first storage 3 , also supported by said turret 2 .

[0049] In the operating station 21 , all steps of processing the capsules 200 are performed sequentially during the rotation of the turret 2 with the continuous movement. Empty capsules 200 from the first store 3 reach the operating station 21 via a corresponding supply duct 22 . In the operating station 21 , the capsules 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com