Aluminum section bar surface brightening method

An aluminum profile, anodizing tank technology, applied in the direction of surface reaction electrolytic coating, anodizing, electrolytic coating, etc., can solve the problems of erosion, surface color is not acid and alkali resistance, electrophoretic paint is easy to peel off, etc., to slow down the paint film speed, reduce production speed, improve adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

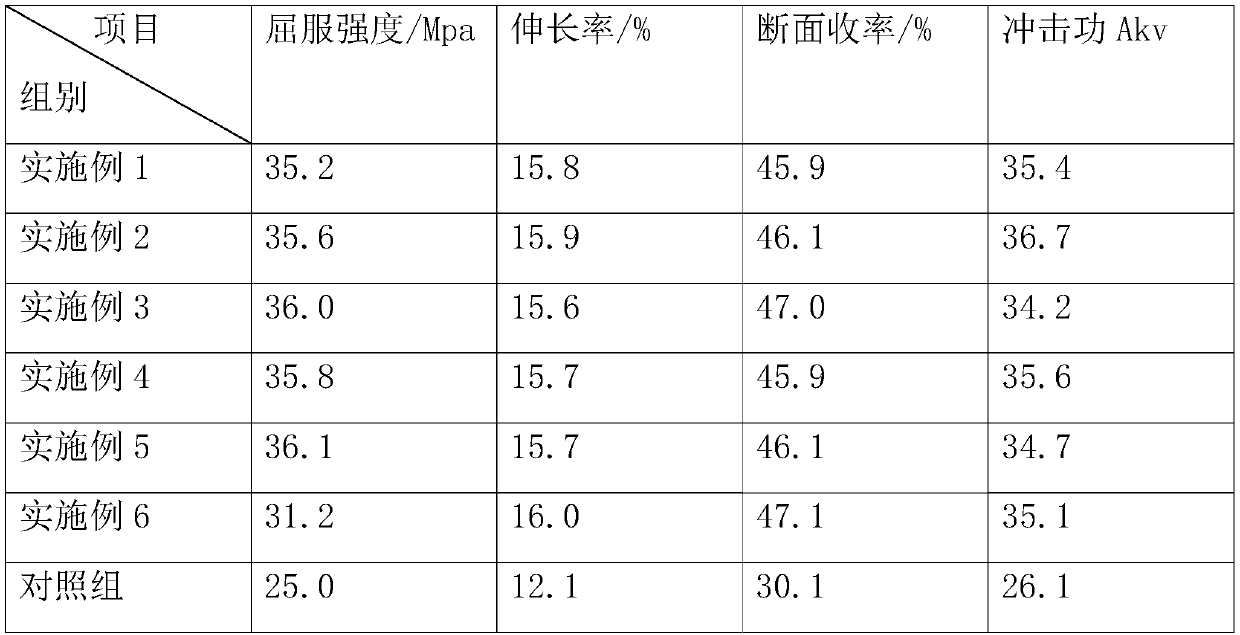

Examples

Embodiment 1

[0021] A method for brightening the surface of an aluminum profile includes the following steps:

[0022] (1) Sandblasting process: Put the aluminum profile blank into a conveying device that uses compressed air as the power to form a high-speed jet beam, and use 0.1 stainless steel sand for surface sandblasting;

[0023] (2) Steps of the degreasing method: After the aluminum profile is discharged, add degreasing agent to the degreasing tank, the addition amount is 45g / / L, the temperature of the degreasing tank is 45℃, and the treatment time is 5min;

[0024] (3) Triacid polishing step: The polishing is carried out in a polishing tank, which contains 65 weight percent phosphoric acid, 22% sulfuric acid, and 8% nitric acid, and the temperature in the polishing tank is 110°C, and the polishing time is 20 minutes ;

[0025] (4) Oxidation step: the aluminum profile is anodized in an anodizing tank, the anodizing treatment time is 20 minutes, the temperature is 16°C, and the free sulfuric ...

Embodiment 2

[0032] A method for brightening the surface of an aluminum profile includes the following steps:

[0033] (1) Sandblasting: Put the aluminum profile blanks into the conveying equipment that uses compressed air as the power to form a high-speed jet beam, and use 0.15mm stainless steel sand for surface sandblasting;

[0034] (2) Degreasing step: After draining the aluminum profile, add degreasing agent to the degreasing tank example, the addition amount is 50g / / L, the temperature of the degreasing tank is 80℃, and the treatment time is 45min;

[0035] (3) Three-acid polishing step: polishing is carried out in a three-acid polishing tank. The polishing tank contains 85% phosphoric acid, 22% sulfuric acid, and 8% nitric acid by weight, stirring and mixing, and soaking for 25 minutes at a temperature of 110°C;

[0036] (4) Oxidation step: the aluminum profile is anodized in an anodizing tank, the anodizing treatment time is 10 min, the temperature is 18°C, and the free sulfuric acid concent...

Embodiment 3

[0043] A method for brightening the surface of an aluminum profile includes the following steps:

[0044] (1) Sandblasting process: Put the aluminum profile blank into the conveying equipment that uses compressed air as the power to form a high-speed jet beam, and use 0.12mm stainless steel sand for surface sandblasting;

[0045] (2) Degreasing step: After draining the aluminum profile, add degreasing agent to the degreasing tank example, the addition amount is 47g / / L, the temperature of the degreasing tank is 60℃, and the treatment time is 20min;

[0046] (3) Tri-acid polishing step: using a tri-acid polishing tank for polishing, stir and mix 70% phosphoric acid, 14-22% sulfuric acid, and 6-8% nitric acid by weight, and soak for 22 minutes at a temperature of 100;

[0047] (4) Oxidation step: the aluminum profile is anodized in an anodizing tank, the anodizing treatment time is 15 minutes, the temperature is 17°C, and the free sulfuric acid concentration in the anodizing tank is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com