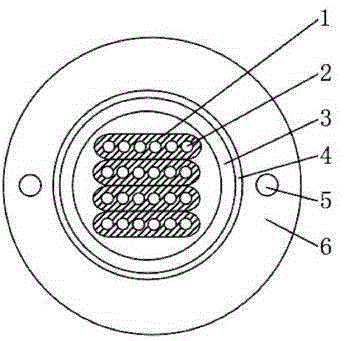

Layer-stranded ribbon fiber cable for electric power or communication

A ribbon optical cable and layer technology, applied in the field of materials and cables, can solve problems such as unreasonable water blocking effect, increased cost of ointment, and difficult construction, so as to save procurement and storage, reduce transportation costs, inspection and The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] And tape resin, it is characterized in that it comprises the following each raw material by weight: polyacrylic resin: 90~95 parts, the ultraviolet curing agent that commercially available model is 3091: 3~5 parts, commercially available model is the ultraviolet light triggering of UV500 Agent: 6-8 parts, commercially available polyisobutylene of model PB2400: 5-8 parts, commercially available polymer thermoplastic synthetic rubber of model SV150: 3-5 parts, commercially available model of anti-corrosion agent for cables of L-1035 Oxidizing agent: 1-2 parts, manganese carboxylate: 1-2 parts, potassium carboxylate: 1-2 parts, sodium fluoride: 2-4 parts.

[0033] The most preferred formulation of the above-mentioned tape resin is: it contains the following raw materials in parts by weight: polyacrylic resin: 93 parts, a commercially available model is 3091 UV curing agent: 4 parts, a commercially available model is UV500 UV light trigger Agent: 7 parts, commercially availab...

Embodiment 2

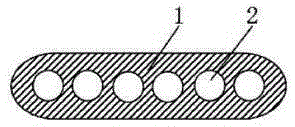

[0040] please see figure 1 , an optical fiber ribbon, which includes 6 optical fibers 2, characterized in that the optical fibers are arranged horizontally, the maximum distance between the centers of adjacent optical fibers is 270 μm, and the maximum flatness of the optical fiber ribbon is 35 μm. The optical fiber is integrally covered with the adhesive resin 1 described in Example 1.

Embodiment 3

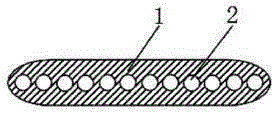

[0042] please see figure 2 , an optical fiber ribbon, which includes 12 optical fibers 2, characterized in that the optical fibers are arranged horizontally, the maximum distance between the centers of adjacent optical fibers is 270 μm, and the maximum flatness of the optical fiber ribbon is 35 μm. The optical fiber is integrally covered with the adhesive resin 1 described in Example 1.

[0043] In the optical fiber ribbon described in the implementation examples, the number of optical fibers is not limited to 6 and 12, and may be other integers from 2 to 24.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com