Decorating strip caulking groove automatic groove cutting machine and processing technology

A technology for decorative strips and grooving machines, used in metal processing and other directions, can solve the problems of affecting the appearance of insulating glass, high labor intensity, easy to skew and fall off, etc., and achieve the effect of saving raw materials, high degree of automation, and improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

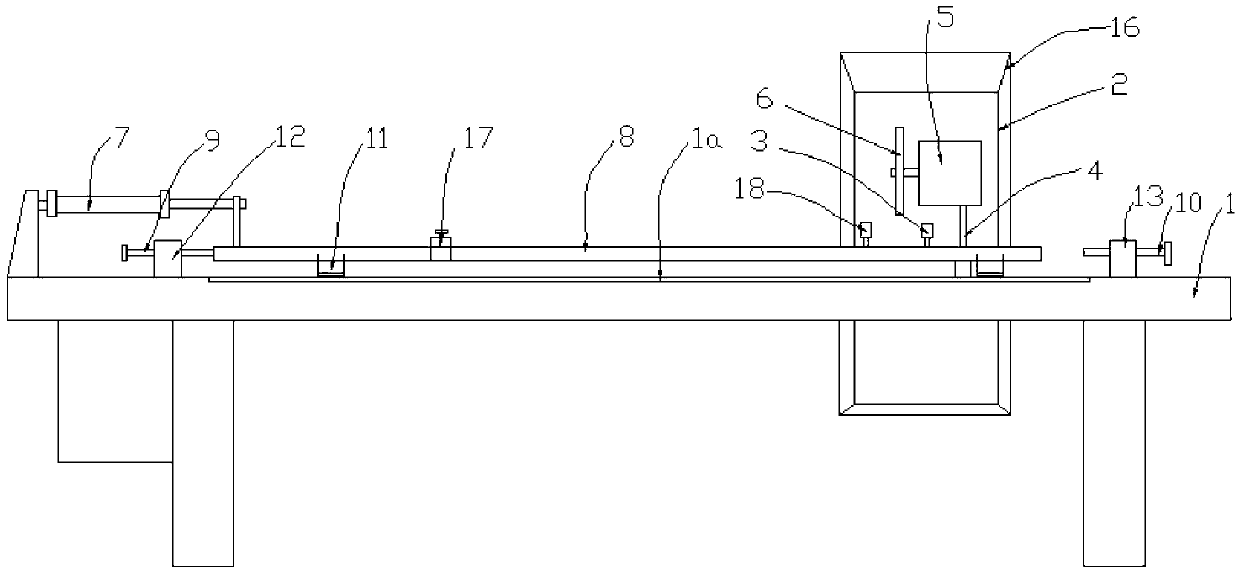

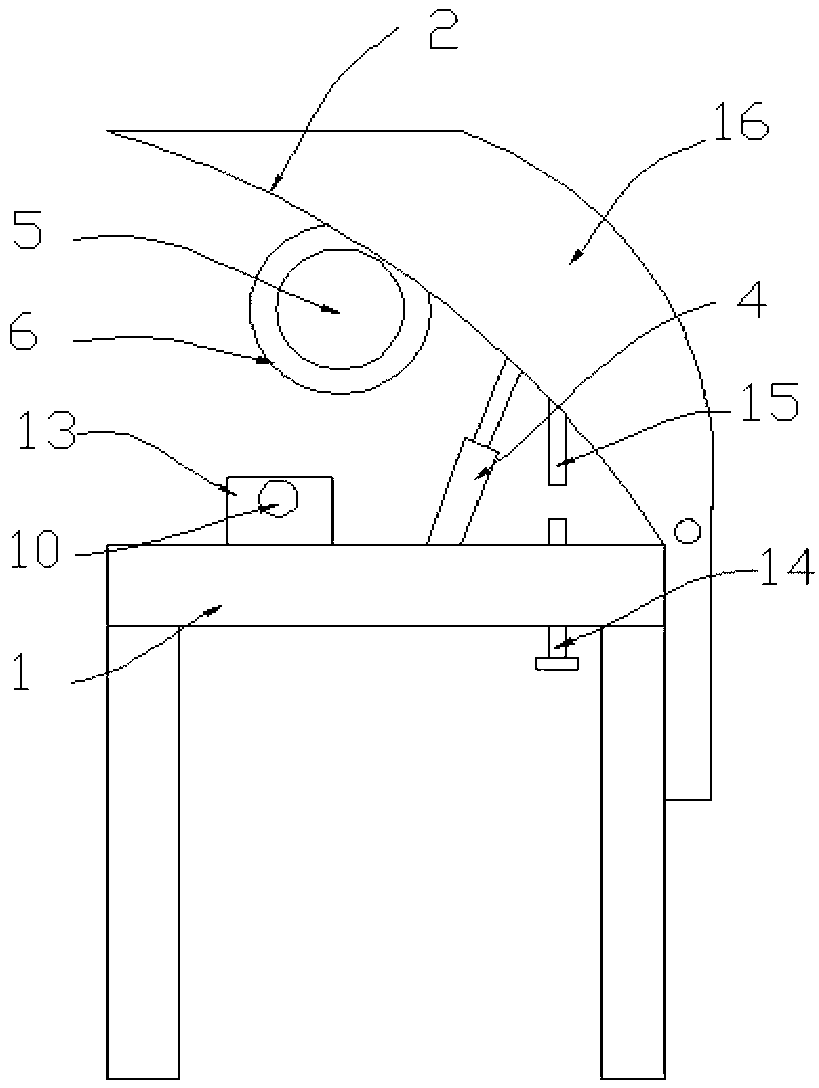

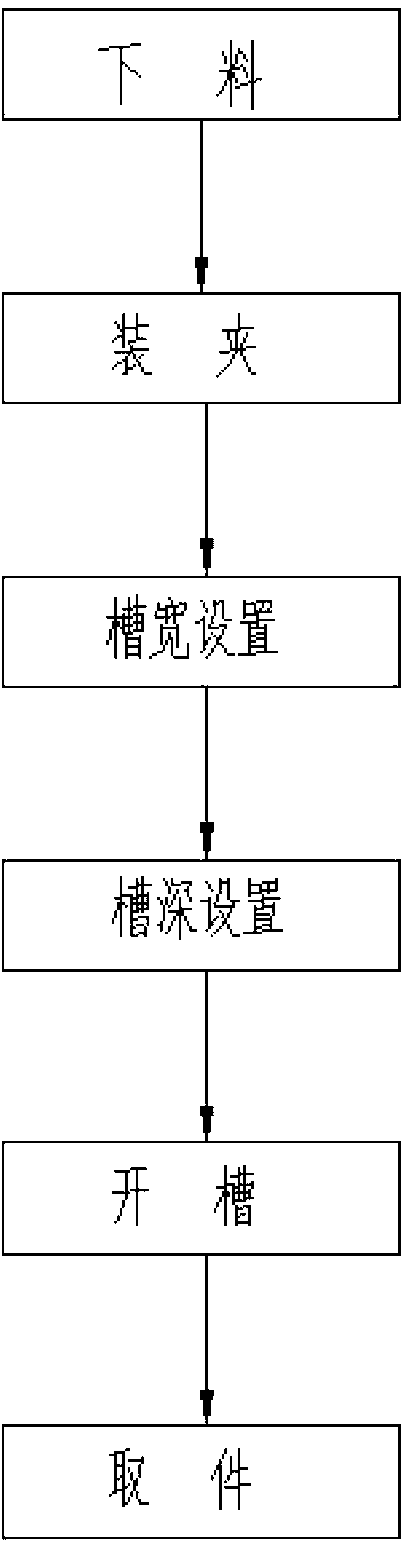

[0026] Such as figure 1 , figure 2 The shown automatic groove cutting machine for decorative strip embedding includes a workbench 1, a cutting frame 2 is hinged on one side of the workbench 1, a rotating shaft is installed on the workbench 1, and the cutting frame 2 Set on the rotating shaft, so the cutting frame 2 can rotate around the rotating shaft, a lower saw cylinder 4 is installed between the cutting frame 2 and the workbench 1, and the cylinder body of the lower saw cylinder 4 is fixed on the On the workbench 1, the piston rod of the saw cylinder 4 is connected to the cutting frame 2, a cutting motor 5 is fixed on the cutting frame 2, and a cutting saw 6 is fixedly sleeved on the output shaft of the cutting motor 5. , start the saw cylinder 4, the cutting frame 2 can be moved up or down, so as to ensure that the cutting saw 6 gives way and cuts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com