Inclined hole of electro-hydraulic servo valve core drill and clipper for countersunk head ascopore

A technology of electro-hydraulic servo valve and inclined hole drilling, which is applied in the direction of the drilling mold used for the workpiece, etc., can solve the problem of inaccurate positioning of the fixture, and achieve the effect of improving processing efficiency, reducing hardness requirements, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

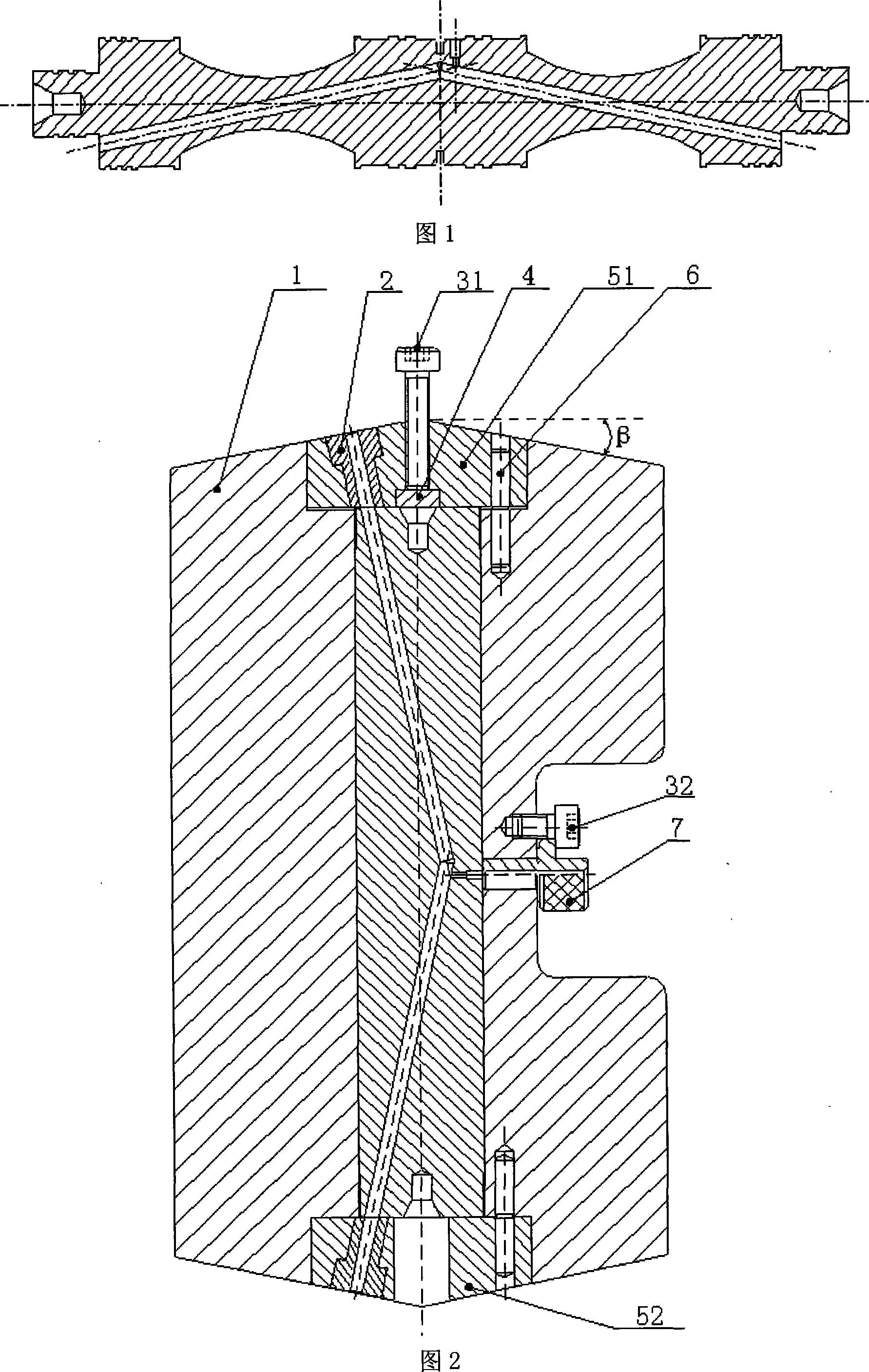

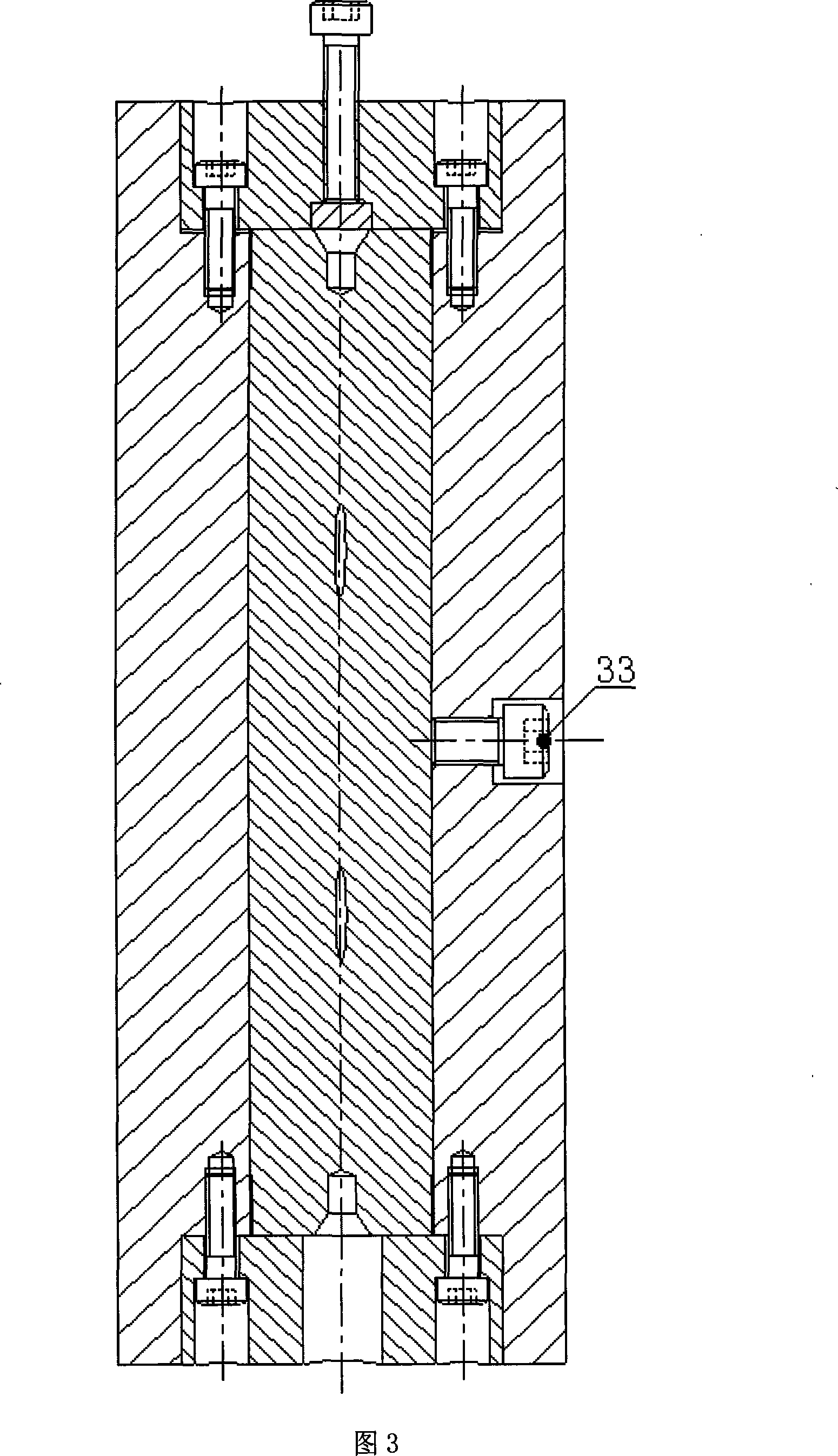

[0021] As shown in Fig. 2 and Fig. 3, first press fit the two drill sleeves 2 into the two drill sleeve seats 51, 52 respectively, press the two cylindrical pins 6 into the drill mold body 1 respectively, and then pass the drill sleeve seat 52 through The cylindrical pin 6 is positioned and fixed on one end of the jig body with screws, loaded into the valve core of the processed part, and then the drill sleeve seat 51 is positioned and fixed on the other end of the jig body through the cylindrical pin, the valve core is pressed, and the screw 33 is tightened to prevent The spool rotates when drilling the slanted hole, and two quick-change drill bushings 7 are put on, the countersunk small hole in the middle of the spool is drilled first, and then two slanted holes are drilled respectively. The small countersunk hole in the middle of the spool and the two inclined holes are processed in one clamping, which ensures the inclination angle and symmetry of the two slanted holes and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com