Double-tilt-angle universal milling head rotating shaft locating precision measuring device

A technology of universal milling head and positioning accuracy, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc. Guaranteeing the needs of five-axis high-precision machining and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

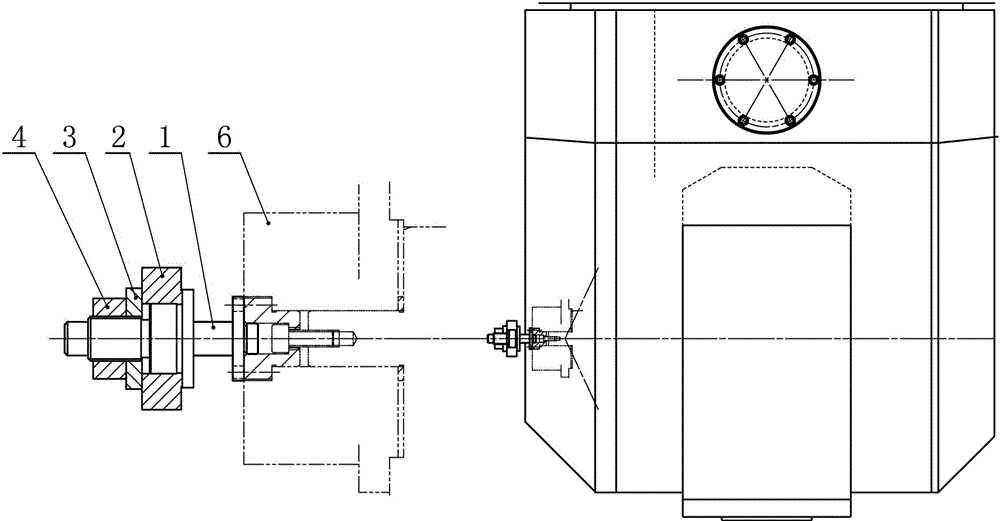

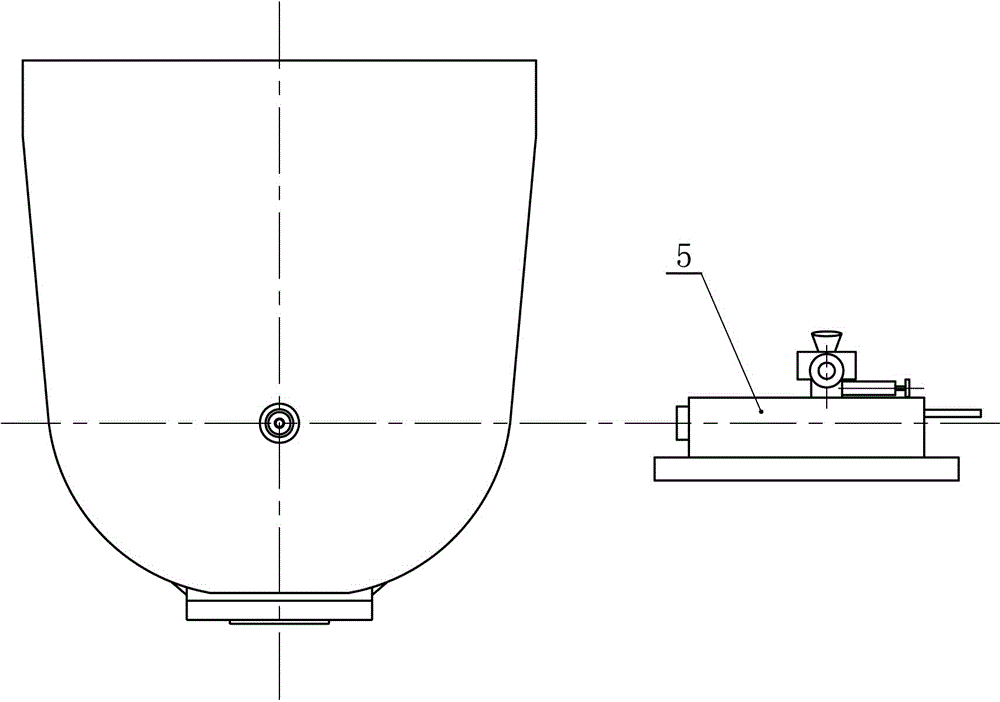

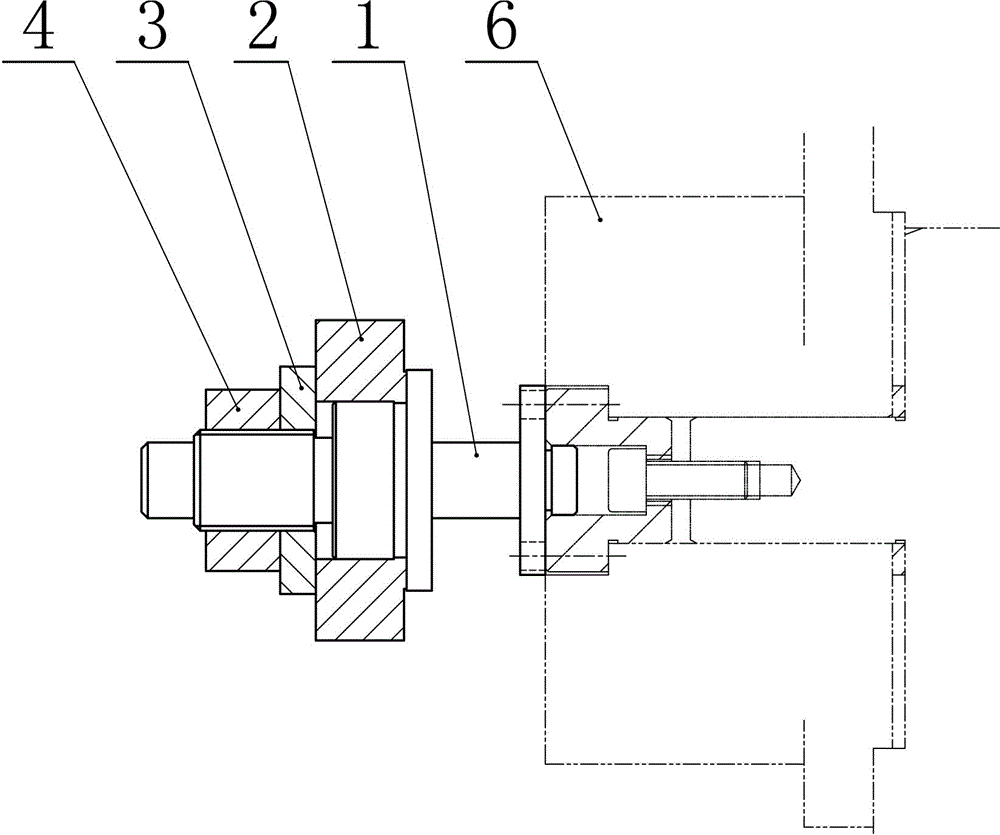

[0025] The present invention as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention includes a positioning shaft 1, a 12-hedron or 36-hedron prism 2, a gland 3, a nut 4, and an autocollimator 5. The positioning axis 1 is a precision machined part, which strictly guarantees the coaxiality and the verticality of the positioning end face. The positioning axis is connected to the A / B and C rotation axes for positioning. The connection is convenient and the accuracy is high. The 12-sided or 36-sided body and the positioning axis Through the positioning of the journal and the end face, the gland 3 and the nut 4 are used to fix it on the positioning shaft, and the operation is simple and convenient.

[0026] At present, the A / B axis positioning detection of the double pendulum universal milling head basically has three structures according to the different output structures:

[0027] 1. The encoder gland is fixed, and the output part is a hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com