Method for processing TC4 titanium alloy into forged rings

A processing technology, titanium alloy technology, applied in the processing technology field of rare and precious metal products, can solve problems such as unreasonable process flow, unguaranteed heating equipment and temperature, great differences in mechanical properties and structures, etc., to achieve easy process and actual measurement The effect of excellent data and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

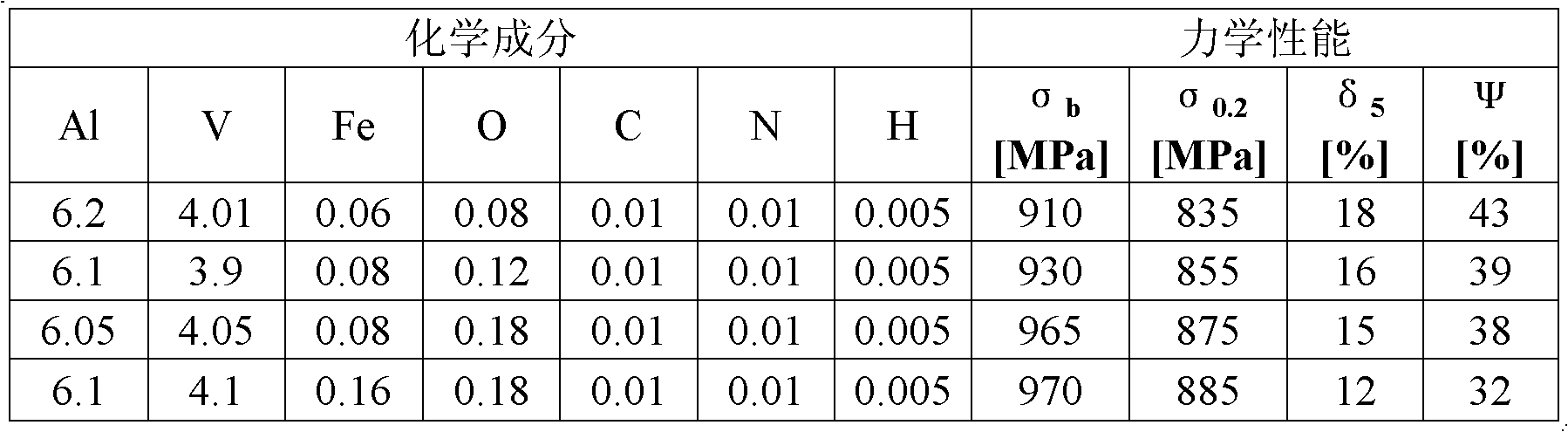

[0025] According to the needs of the actual situation, we need to base the performance of the TC4 material on the basis of the basic requirements, and strive to improve the mechanical properties of the material to the greatest extent through the adjustment of other components in the alloy, so that the material can reach or exceed the maximum extent in use. Use requirements, even if the tensile strength is increased, the plasticity is not reduced. This requires finding an optimal range in terms of the chemical composition ratio of the material. We find the most suitable range of oxygen and iron element content through the comparison of the influence of the following composition ratios on the material properties. The longitudinal samples of Φ50TC4 rods with different components under the same processing technology conditions are taken for testing.

[0026]

[0027] From the comparison of the above data, it can be seen that the increase of iron and oxygen elements both increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com