Straightness detection device for inner hole of spindle storing drum

A detection device and straightness technology, applied in the direction of angle/taper measurement, etc., can solve the problems of high production cost and difficult precision, achieve the effect of quick disassembly, avoid waste of resources, and create economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

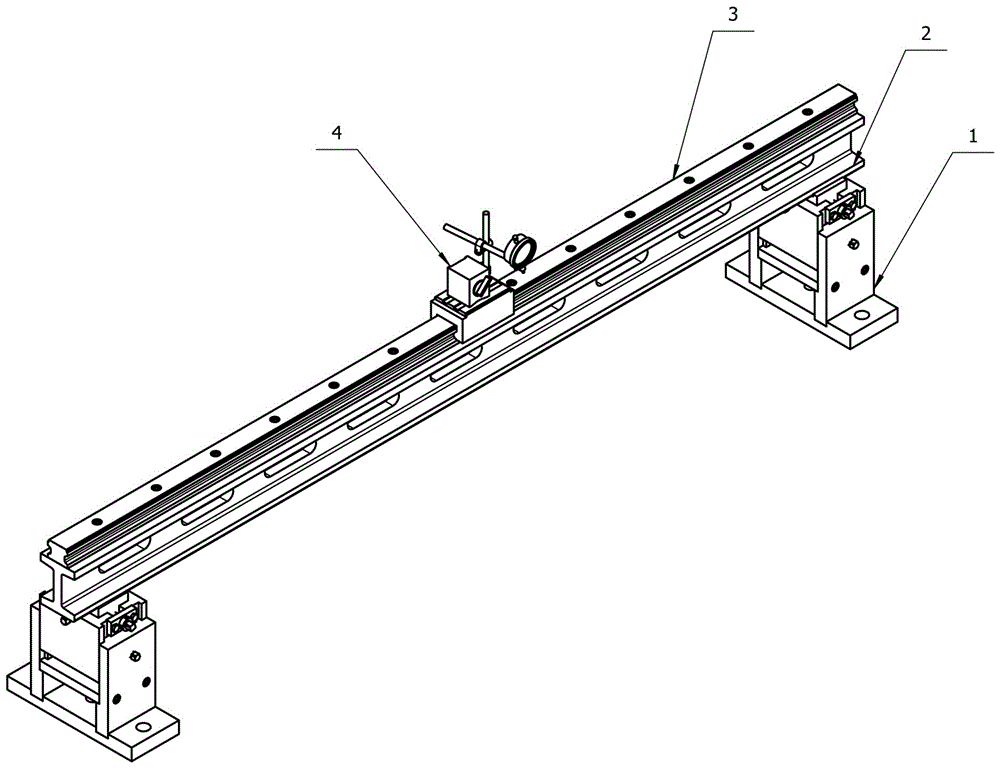

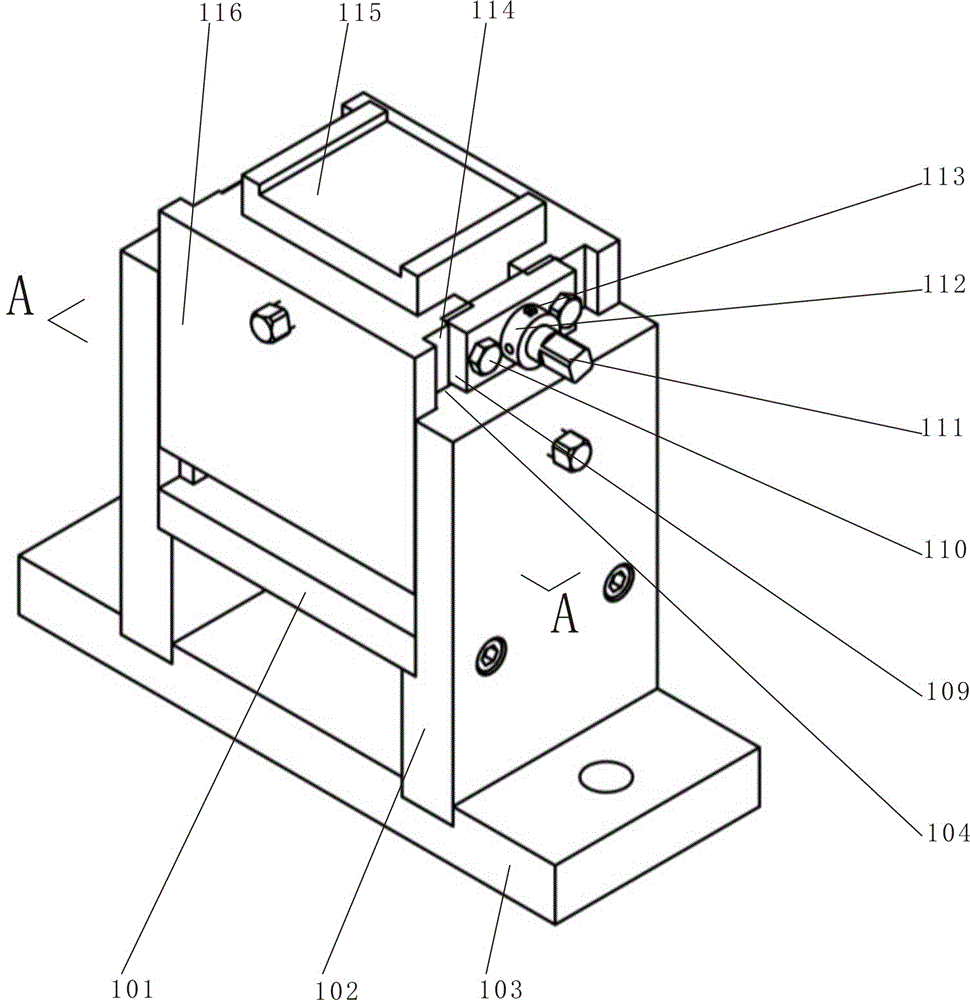

[0025] A straightness detection device for the inner hole of an ingot tube, comprising two adjustment bases 1, a ruler guide rail 2, a linear slider 3 and a dial indicator 4; the two ends of the ruler guide rail 2 are respectively arranged on an adjustment base 1, the upper end of the ruler guide rail 2 is provided with a linear slider 3 consistent with the length of the ruler guide rail 2, the dial indicator 4 is arranged on the linear slider 3, and the upper and lower ends of the dial indicator 4 are provided with linear The chute that the slider 3 cooperates with; the adjustment base 1 is also provided with a vertical adjustment mechanism and a horizontal adjustment mechanism.

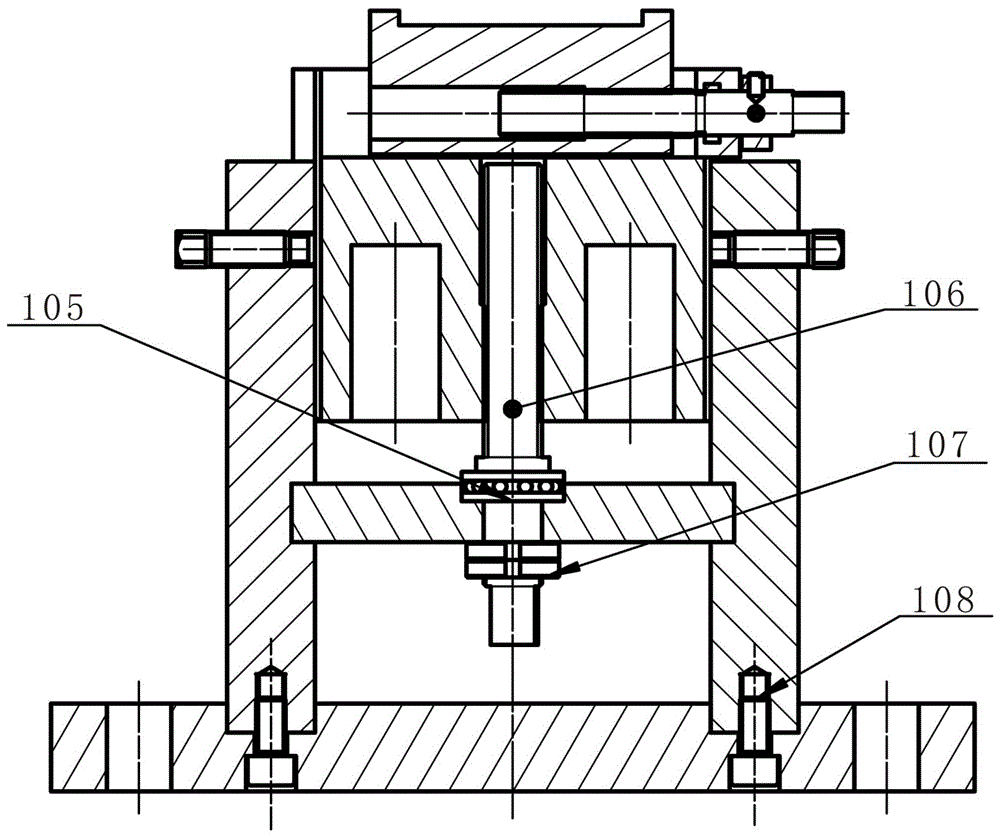

[0026] Described adjustment base 1 comprises base plate 101 and two suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com