Glue coating machine for wallpaper

A coating machine and wallpaper technology, which is applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of uneven paper material, difficulty in controlling the amount of glue rolled by the rubber roller, and uneven sizing, so as to prevent uneven wallpaper material Uniform and reduce the effect of bad wallpaper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

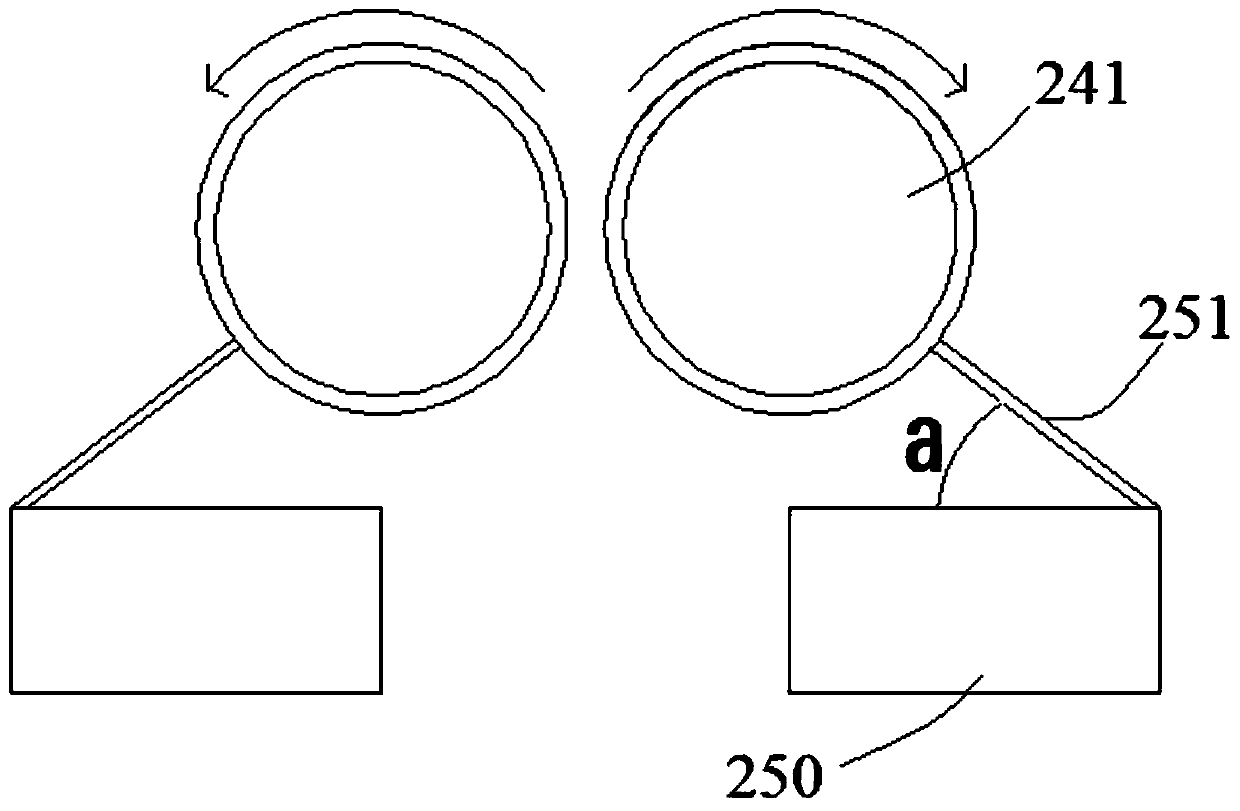

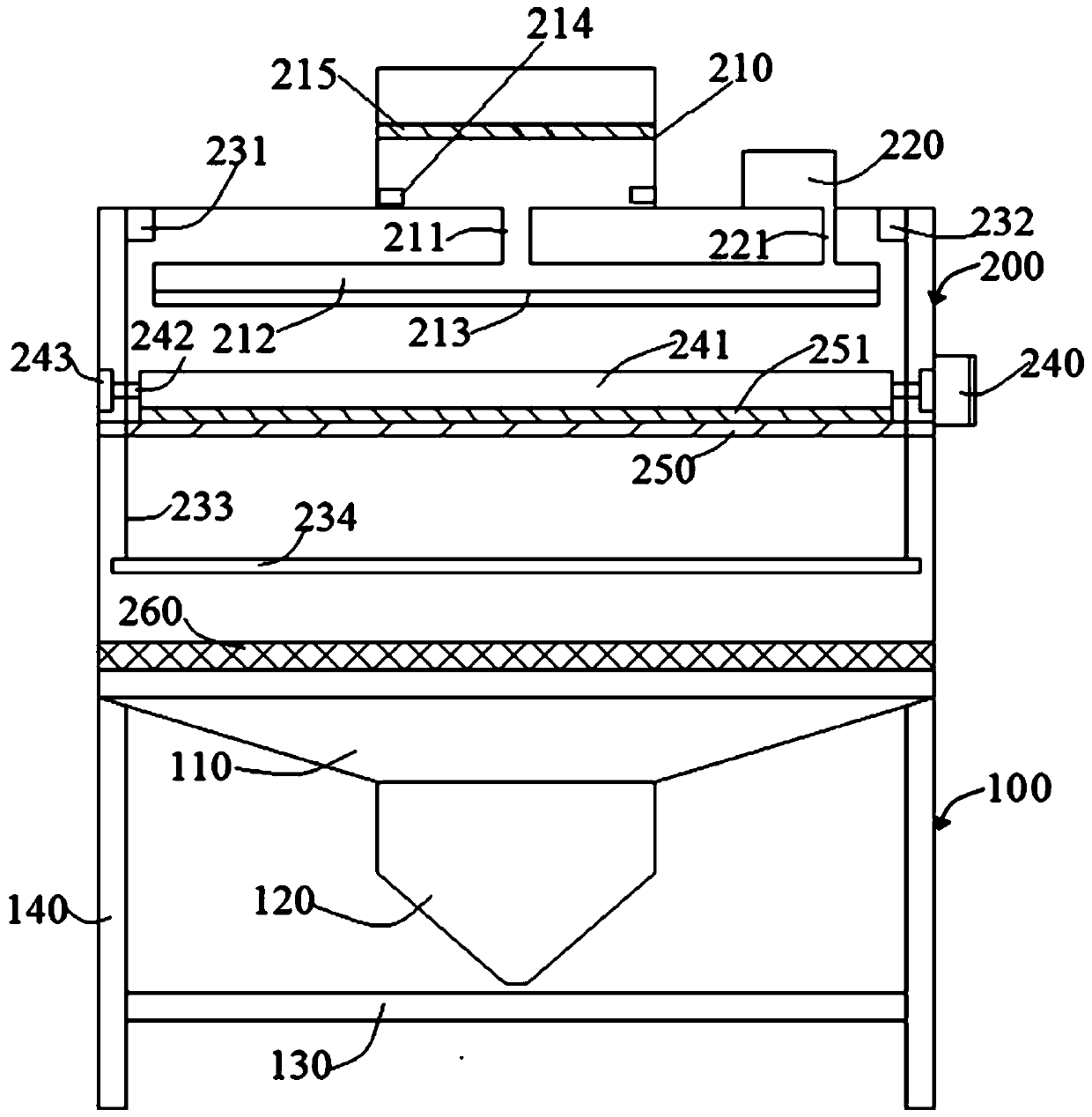

[0026] Refer to attached figure 1 - attached figure 2 , a wallpaper sizing coating machine of the present embodiment comprises a base 100 and a sizing device 200 installed on the base 100, the sizing device 200 includes a driving motor 240 arranged on the side, and the driving motor 240 passes through a belt The rubber rolling shaft group 241 is connected, and the rubber rolling shaft group 241 is arranged directly below the glue spraying pipe 213. The rubber rolling shaft group 241 includes two rubber rolling shafts arranged in parallel. On the side wall of the device 200, the rubber rollers are connected with the belt through the rolling shaft 242, and the rubber scraper fixing rods 250 are arranged directly below the two rubber rollers, and the rubber scraper fixing rods 250 are provided with an inclined scraper blade 251, which is The film 251 is in contact with the lower side of the rubber roller, the angle a between the rubber scraper 251 and the rubber fixing rod 250 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com