Polaroid attaching device and polaroid attaching method

A technology for attaching polarizers and polarizers, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as polarizer drop and adsorption, and achieve the effect of increasing the probability of blocking inspection and reducing poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

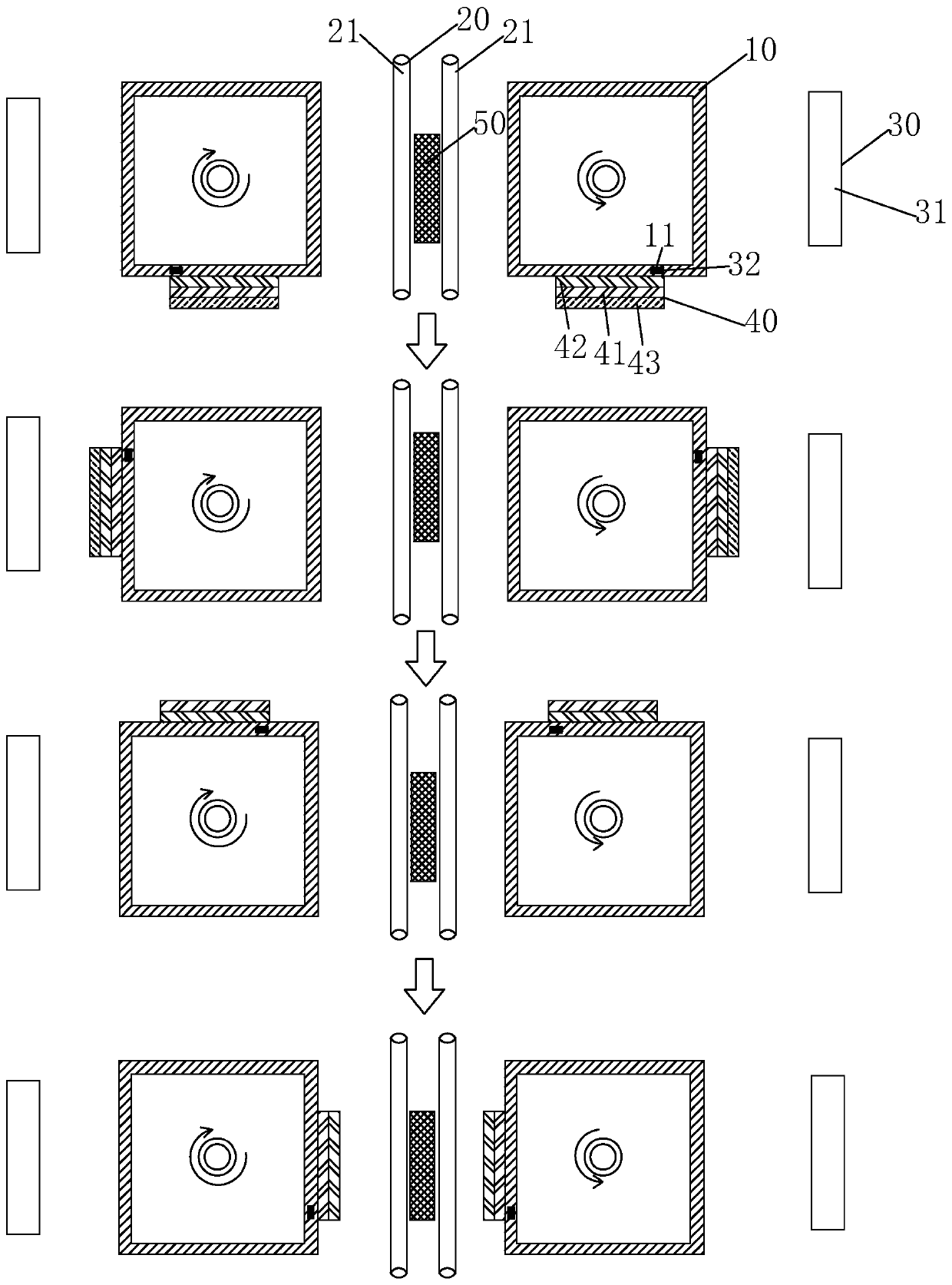

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

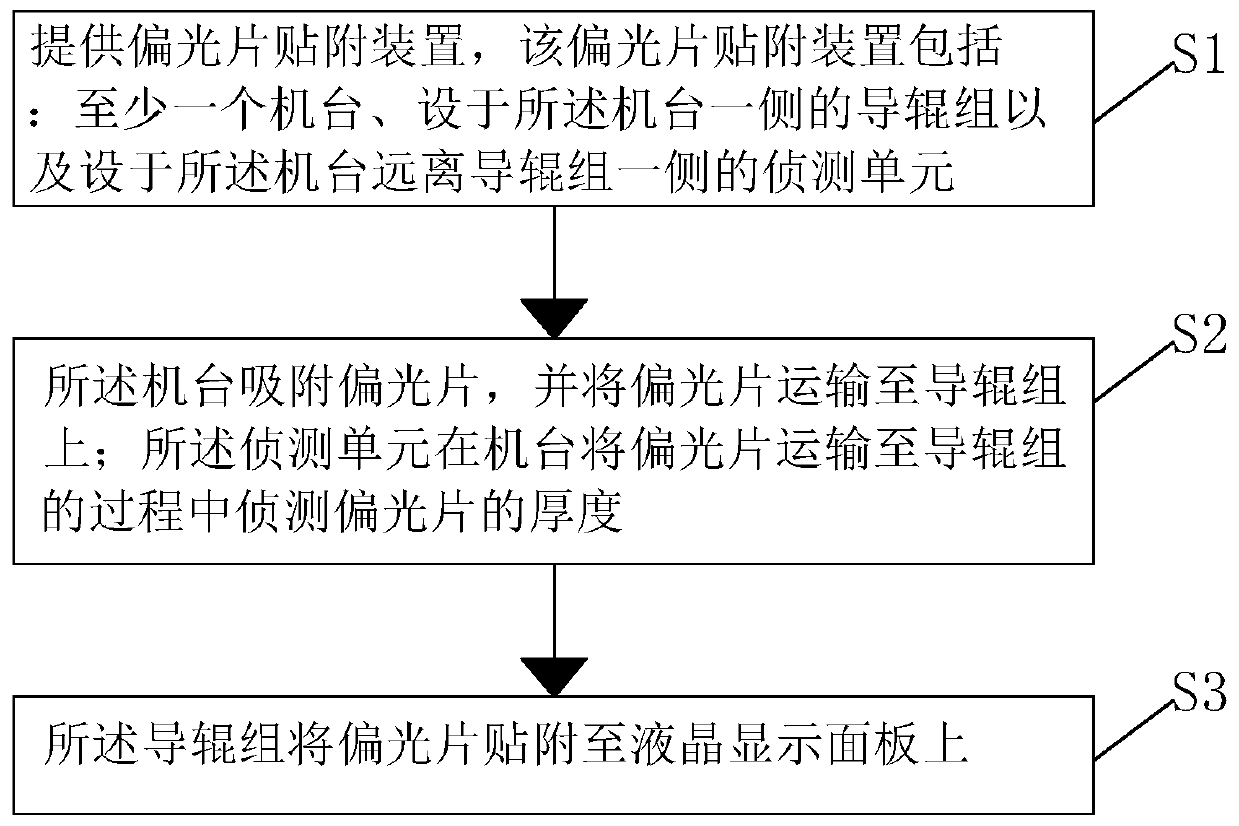

[0034] see figure 1 , the present invention provides a polarizer sticking device, comprising: at least one machine table 10, a guide roller set 20 arranged on one side of the machine table 10, and a guide roller set 20 arranged on the side of the machine table 10 away from the guide roller set 20 detection unit 30;

[0035] The machine 10 is used to absorb the polarizer 40, and transport the polarizer 40 to the guide roller set 20;

[0036] The guide roller set 20 is used to attach the polarizer 40 to the liquid crystal display panel 50;

[0037] The detection unit 30 is used for detecting the thickness of the polarizer 40 when the machine 10 transports the polarizer 40 to the guide roller set 20 .

[0038] It should be noted that, in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com