Two-channel vertical type edge curling machine

A crimping machine, double-channel technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem of out-of-round film rolls of horizontal crimping machines, reduce the service life of parts, and the rubber rollers are easily damaged. Problems such as jumping occur, so as to prevent the difficulty of dismantling the coil diameter, improve production capacity, and reduce the number of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with specific examples.

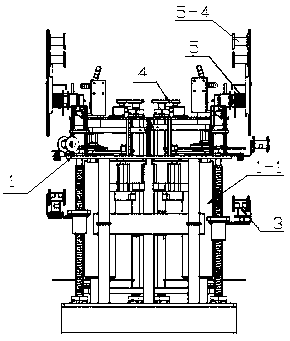

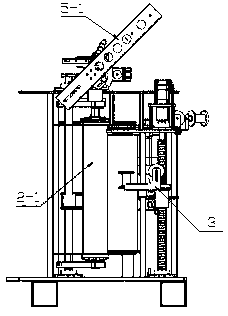

[0020] Such as Figure 1-7 Shown, two-channel vertical crimping machine, including:

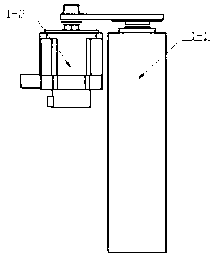

[0021] Rubber rollers, the rubber rollers 1-1 are symmetrically installed on both sides of the frame body 1, the surface of the rubber rollers is rubber, and the rubber rollers are driven by the motor A 1-2 to rotate along the rotating shaft of the rubber rollers 1-1;

[0022] The paper tube is arranged parallel to the rubber roller and is in close contact with the surface of the rubber roller. The rubber roller 1-1 is driven to rotate by friction so that the side strips are wound on the surface of the paper tube 2-1.

[0023] The two ends of the paper tube are respectively equipped with a retractable upper head 2-2 and a fixed lower head 2-3 to clamp the paper tube. The upper and lower slide design of the paper tube upper head 2-2 realizes the rapid replacement of the paper tube. It is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com