Automatic balance weight energy-saving control system for elevator

An energy-saving control system and automatic technology, applied in the direction of sustainable buildings, elevators, lifting equipment in mines, etc., can solve the problems that cannot meet the needs of passengers' life and work efficiency in an emergency, affect the market demand and application prospects of energy-saving elevators, and delay demand problems such as the use of elevators, to achieve the effect of prolonging the life of the elevator, reducing poor quality, and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This embodiment is an elevator automatic counterweight energy-saving control system.

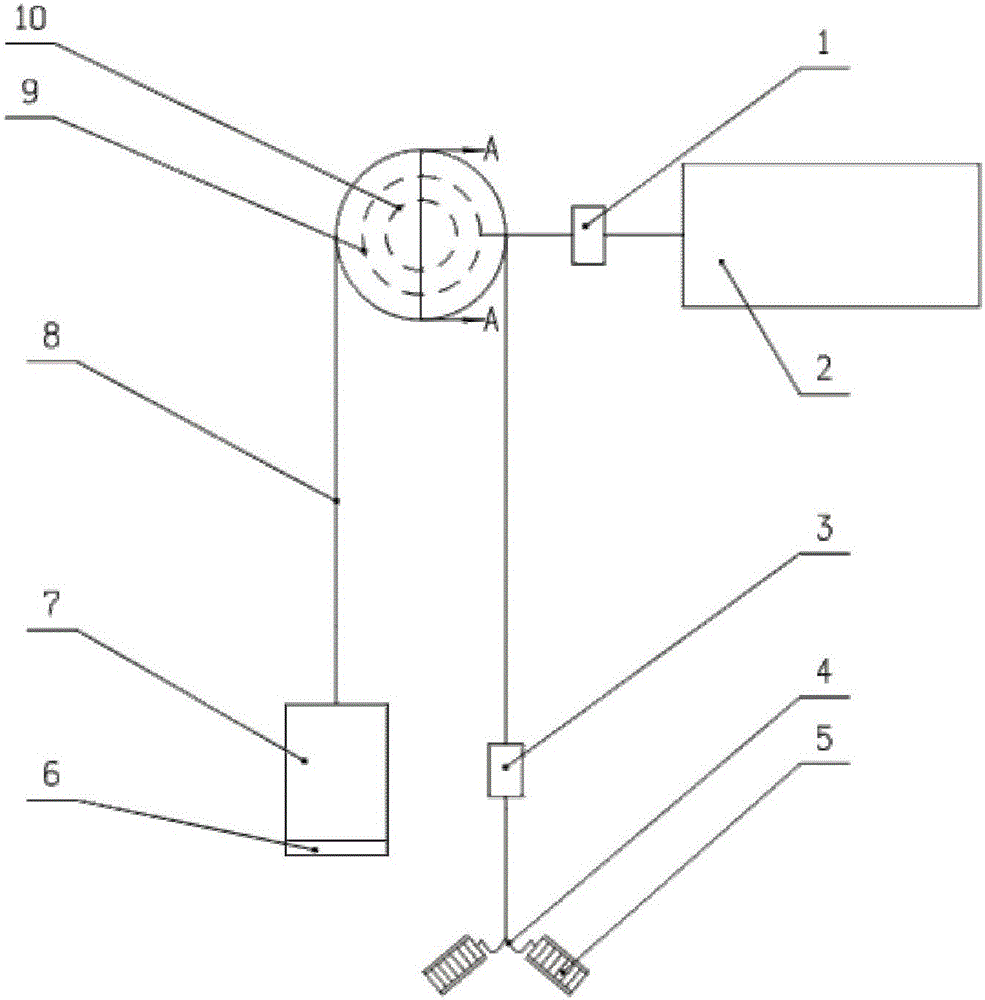

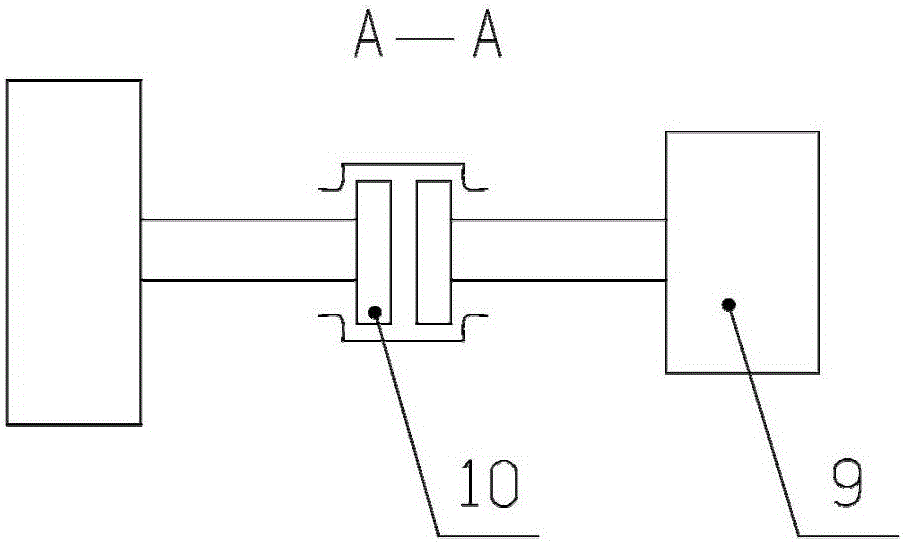

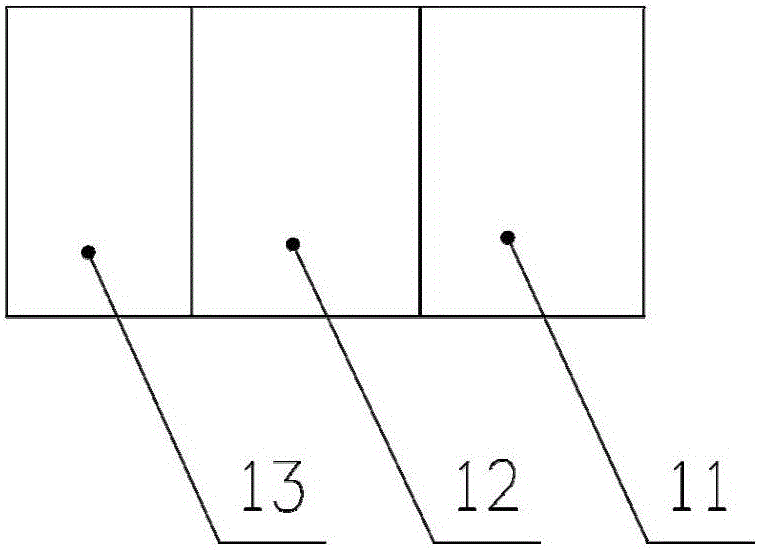

[0015] refer to figure 1 , figure 2 , image 3 , the elevator automatic counterweight energy-saving control system of this embodiment is composed of an automatic counterweight device, a control mechanism 1, an electrical storage device 2, an elevator car 7, a traction steel rope 8, a motor 9, and a clutch 10; the automatic counterweight device includes a pressure Sensor 6, fixed counterweight 3, counterweight assembly 5, eight-claw hook 4, the control mechanism 1 is connected with the pressure sensor 6, the pressure sensor 6 is installed at the bottom of the elevator car 7, and it starts to work when the elevator door is closed. state, the pressure data signal in the elevator car 7 measured by the pressure sensor 6 is transmitted to the control mechanism 1. The control mechanism 1 receives the data from the pressure sensor 6 , and the counterweight assembly 5 selects the counterwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com