Glass etching industry pipe washing agent and washing method thereof

A pipeline cleaning agent and etching technology, which is applied in the field of cleaning agents, can solve problems that affect equipment production efficiency, equipment cannot work normally, and are difficult to remove, so as to save labor costs and time costs, reduce poor quality, and simple cleaning methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

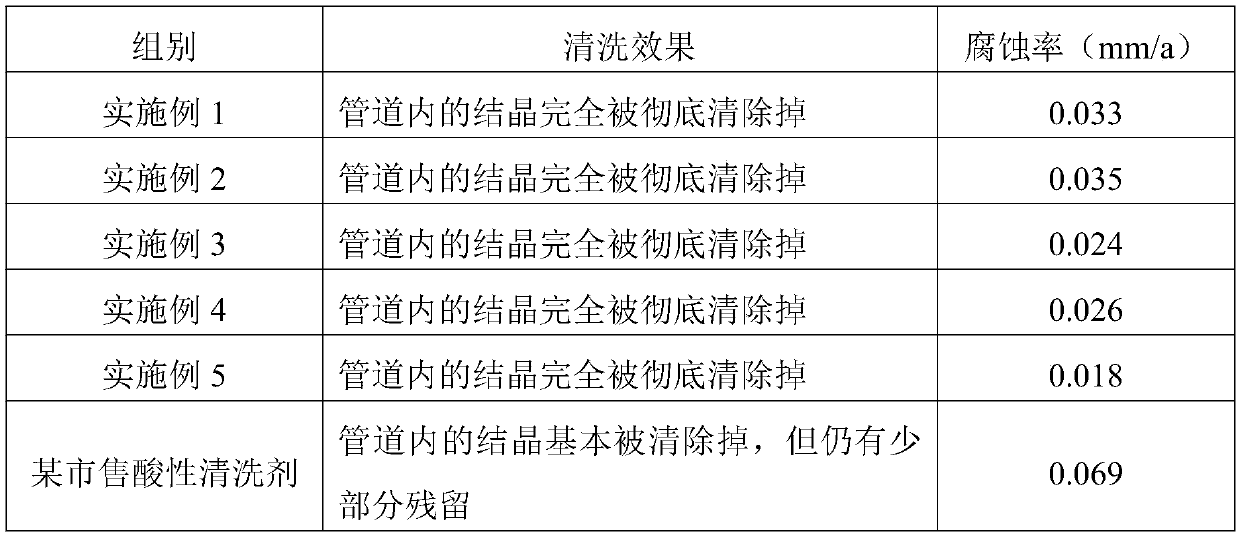

Examples

preparation example Construction

[0021] The embodiment of the present invention also provides a kind of preparation method of glass etching industry pipeline cleaning agent, and this method comprises the steps:

[0022] First mix water and anionic surfactant, stir and mix evenly, add inorganic acid to the mixed liquid, stir again, then add diethylene triamine pentamethylene phosphoric acid, hydrocarbyl thioglycolic acid and Alcohol amine, after stirring and dissolving completely, obtains cleaning agent.

[0023] Embodiments of the present invention also provide a method for cleaning pipelines with a pipeline cleaning agent in the glass etching industry, comprising the following steps:

[0024] Add cleaning agent into the pipeline, soak the cleaning agent in the pipeline for 30-40 minutes, then discharge the cleaning agent; then pass the cleaning agent into the pipeline, heat and rinse the pipeline continuously, after rinsing for 1-3 hours, pour water into the pipeline, rinse 15-20 minutes is enough.

[0025...

Embodiment 1

[0029] Pipe cleaning agent for glass etching industry, comprising the following components in parts by weight:

[0030] 20 parts of hydrochloric acid, 10 parts of boric acid, 6 parts of triethanolamine, 3 parts of diethylenetriaminepentamethylene phosphoric acid, 0.6 parts of hydrocarbyl thioglycolic acid, 8 parts of lignosulfonic acid amine, and water to 100 parts.

[0031] Add the cleaning agent into the pipeline, soak the white powder residue in the pipeline at room temperature for 30 minutes, and then discharge the cleaning agent; then pass the cleaning agent into the pipeline, heat the cleaning agent to 40°C, and continue to rinse with the heated cleaning agent After washing the white powder residue in the pipeline for 3 hours, pour water into the pipeline and rinse for 15 minutes.

Embodiment 2

[0033] 10 parts of hydrochloric acid, 5 parts of boric acid, 2 parts of diethanolamine, 1 part of diethylenetriaminepentamethylene phosphoric acid, 0.3 parts of hydrocarbyl thioglycolic acid, 3 parts of sodium lignosulfonate, and water to 100 parts.

[0034] Add cleaning agent into the pipeline, soak the white powder residue in the pipeline at room temperature for 30 minutes, and then discharge the cleaning agent; then feed the cleaning agent into the pipeline, heat the cleaning agent to 40°C, and the heated cleaning agent will continue to flush the pipeline After washing the white powder residue in the pipe for 2 hours, pour water into the pipeline and wash it for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com