Method of preparing quaternary ammonium type cationic starch

A technology of cationic starch and quaternary ammonium type, applied in the field of preparation of quaternary ammonium type cationic starch, can solve the problems of poor enhancement effect and low substitution degree, and achieves enhanced water filtration effect, reasonable production process, reduced gelatinization temperature and low degree of substitution. Drenched effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

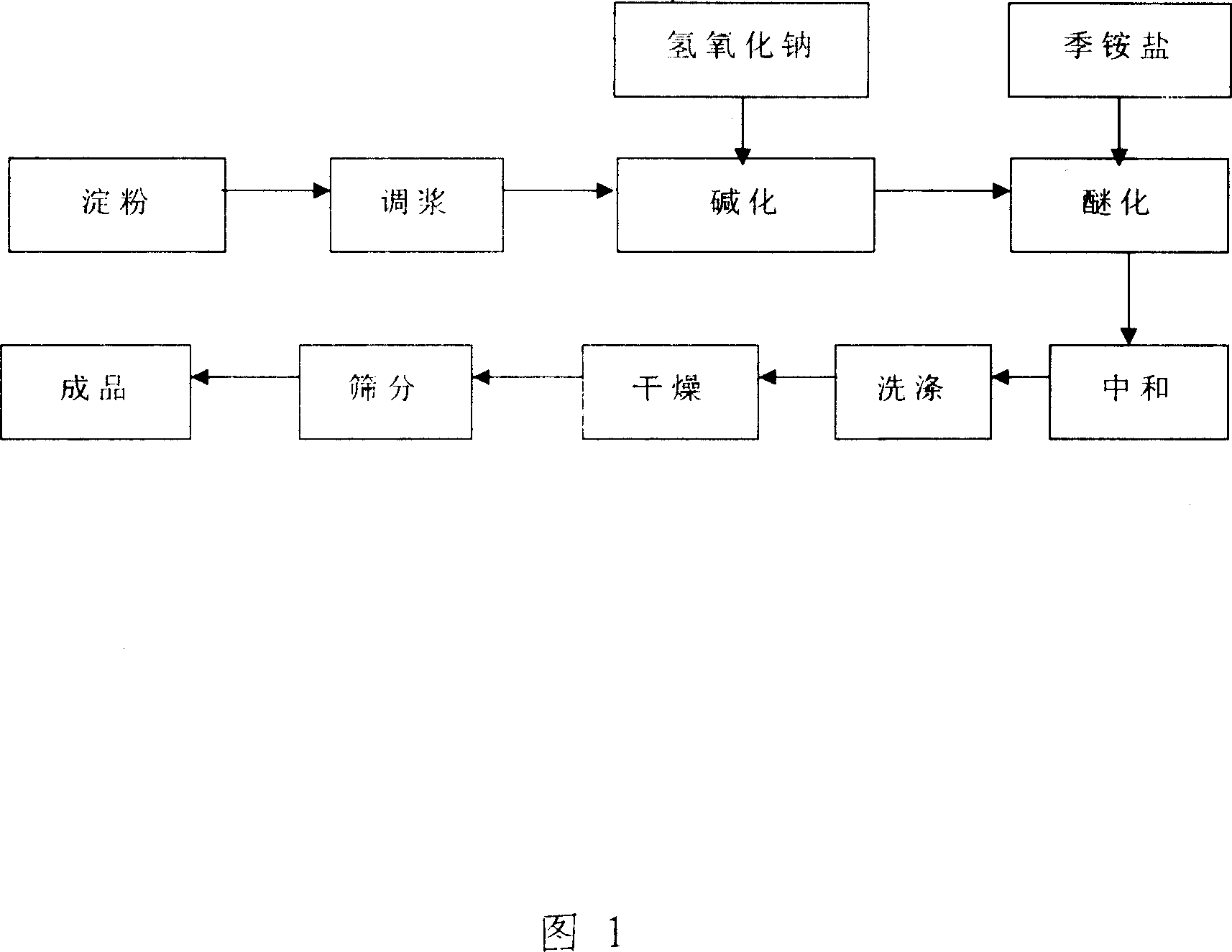

Image

Examples

Embodiment 1

[0020] First, add 1000 catties of cornstarch and 200 kg of sodium sulfate to 1800 kg of water in the reactor to form a starch slurry of 20 to 23 Be, stir continuously, and add sodium hydroxide with a mass concentration of 3 to 3.8% in the reactor to adjust the pH value to 12.0, then add 40 kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride, heat up to 49 ° C for 20 hours, and ensure that the pH value is between 11.0 and 12.0. After the above-mentioned cross-linking etherification reaction is finished, use hydrochloric acid with a mass concentration of 9% to adjust the pH value to 6.0, first wash it with a cyclone washer, and then use a scraper type centrifugal dehydrator to dehydrate to a moisture content of ≤45%, and then use an airflow dryer Dried to make the moisture content reach ≤ 14.0%. The dried starch is sieved with an 80-100-mesh vibrating sieve, and packed in 20-25 kg / bag to finally obtain a finished product.

Embodiment 2

[0022] The steps are the same as in Example 1, except that tapioca starch is used as raw material, and the temperature of the etherification reaction process is maintained at 46°C.

Embodiment 3

[0024] The steps are the same as in Example 1, except that potato starch is used as the raw material, and the temperature in the etherification process is maintained at 47°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com