Manufacturing method of large-scale reciprocating type refrigeration compressor

A technology for refrigeration compressors and compressor cylinders, which is applied in the field of manufacturing large-scale reciprocating refrigeration compressor cylinders, and can solve problems such as wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

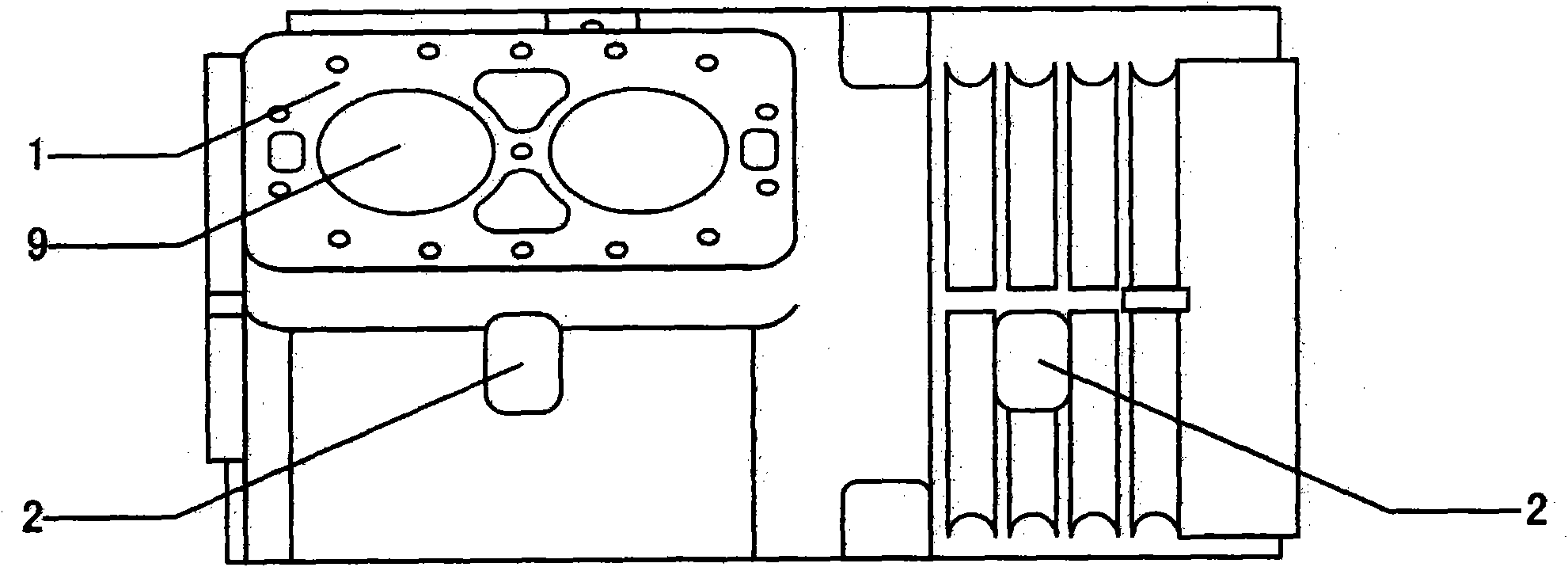

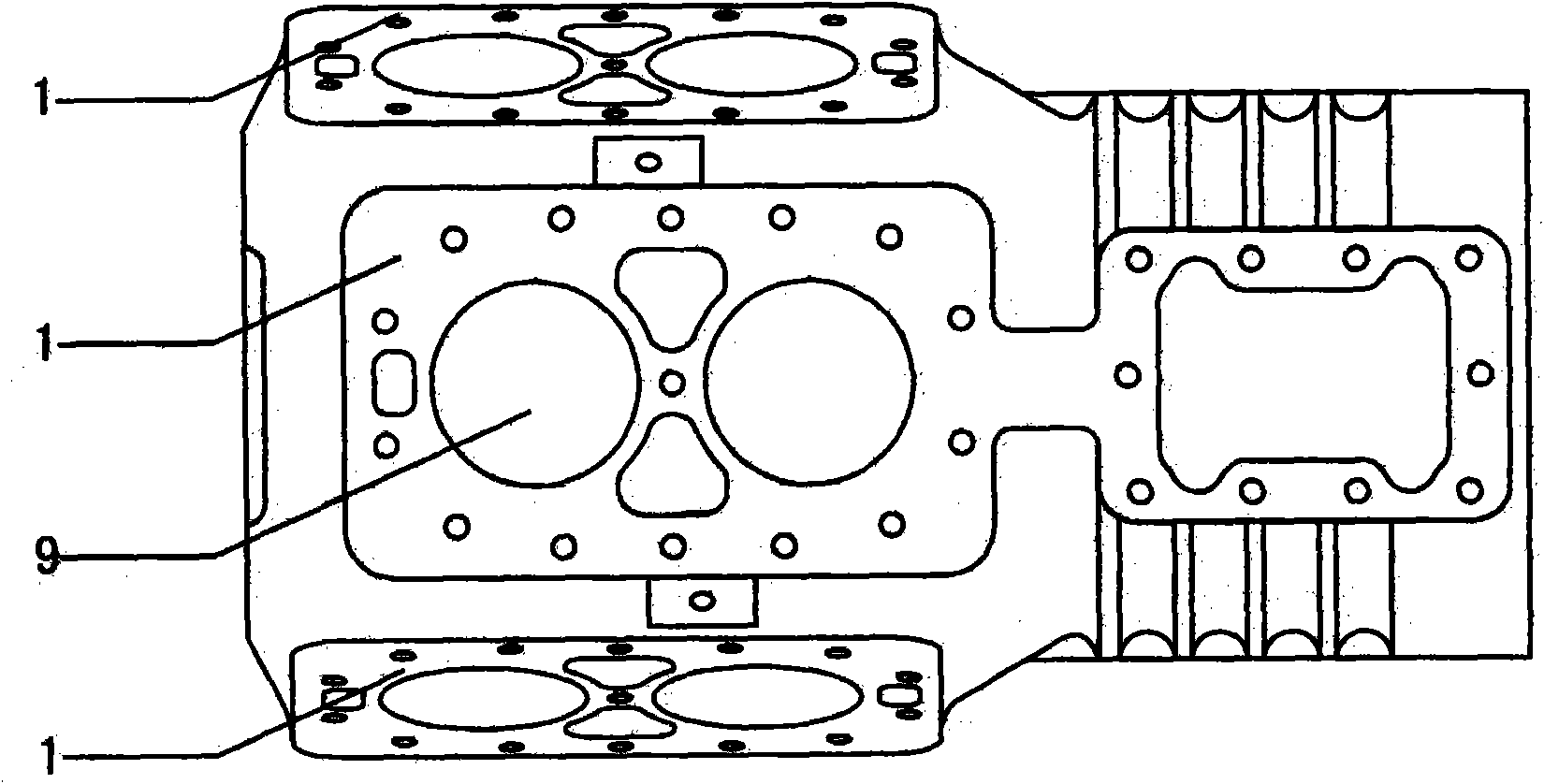

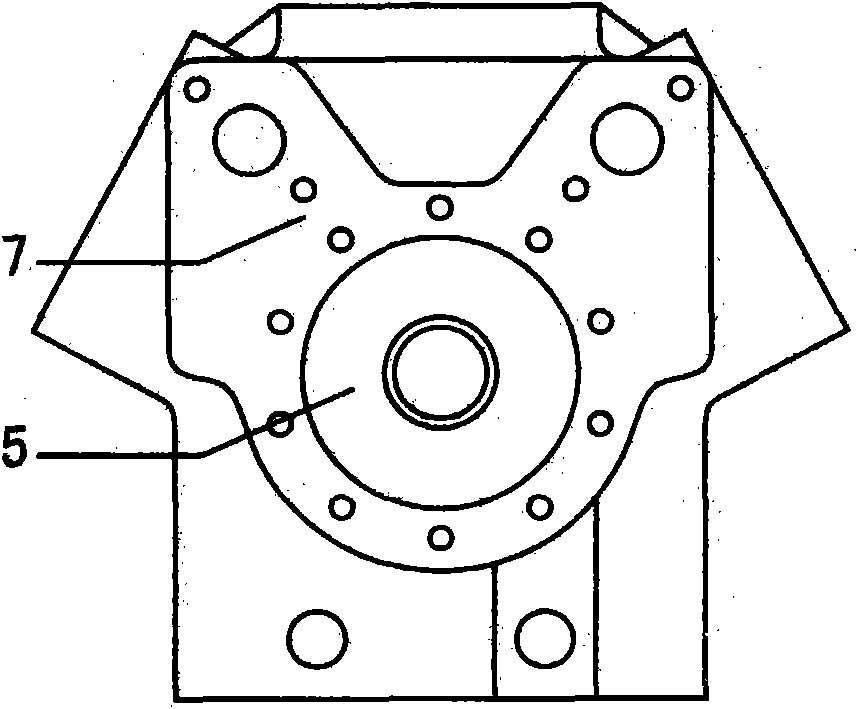

[0035] Select the appropriate cast iron raw material, cast according to the compressor cylinder mold to manufacture the casting body, the hardness is HB225, and use the plane milling machine to carry out plane rough milling on the bottom surface, the cylinder joint surface (1) and the fixed surface (2), Then through the boring machine, carry out synchronous coaxial diameter cylinder boring processing for the main shaft hole (5) of the cylinder body, the motor cavity hole and the end cover hole, and make the surface of the cylinder body cavity and the outer edge contact surface smooth. For rough milling by a milling machine The processed cylinder joint surface (1), fixed surface (2), spindle hole external joint surface (7), and motor cavity external joint surface (8) are finely milled with a milling machine to improve the smoothness of the above surfaces , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com