Production technology for blanking by using a through-hole type universal joint finish forging pot shell capable of moving axially

A technology of axial movement and production process, which is applied in the direction of manufacturing tools, forging/pressing/hammering machinery, couplings, etc., and can solve the problem of a large proportion of surplus materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

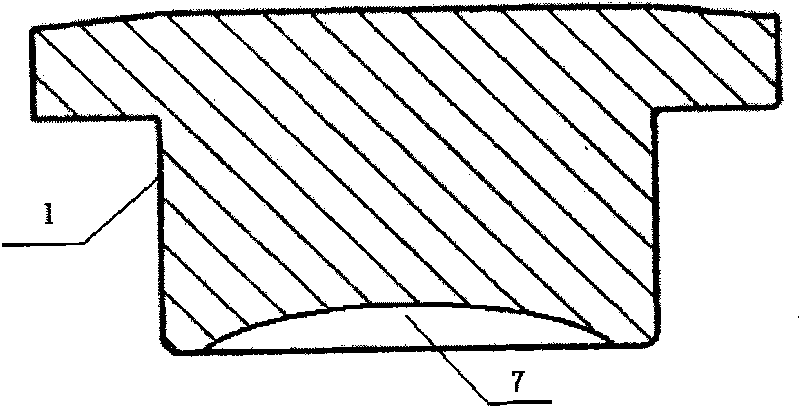

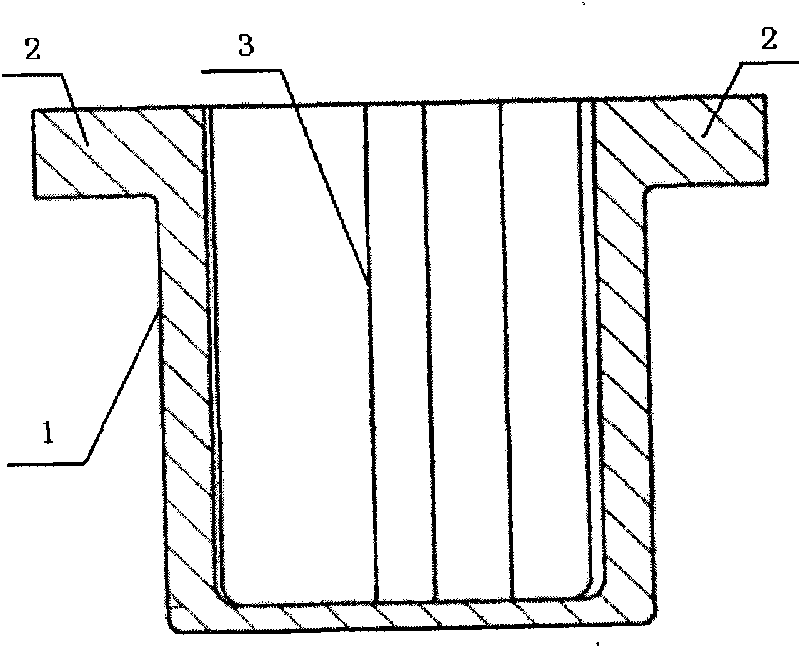

[0016] Embodiment 1: see attached figure 1 with attached figure 2 , a production process for axially movable through-hole universal joint precision forging groove shell blanking, including blanking, heating, and after the metal material is heated after blanking, it is partially upset and extruded in the billet mold , upsetting in a closed cavity to form a rod part 1 and a blank disk part, the rod part 1 is a cylindrical structure, one end is connected with the blank disk part, and the other end is a concave structure, and the concave surface structure The inner cavity 7 is a circular arc surface structure, and the difference between the product of the diameter of the rod part 1 and the maximum length of the rod part 1 and the volume of the rod part is not less than the volume of the inner hole formed by the reverse extrusion of the flange part, and then the preset The formed billet is put into the cavity of the final forging die, and the upsetting billet is back-extruded on ...

Embodiment 2

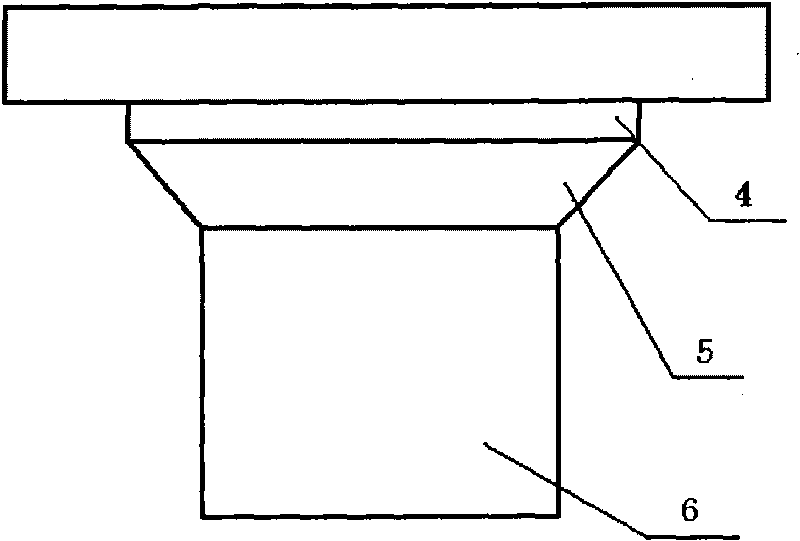

[0017] Embodiment 2: see attached image 3 with attached figure 2 , a production process for axially movable through-hole universal joint precision forging groove shell blanking, including blanking, heating, and after the metal material is heated after blanking, it is partially upset and extruded in the billet mold , upsetting in a closed cavity to form a rod part 1 and a blank disk part, the rod part 1 is divided into three connected sections, the first section 4 and the third section 6 are cylindrical structures with different diameters, the second section The second section 5 is the transition section between the first section and the third section. The transition section 5 is a solid part formed by a circle whose diameter gradually decreases. The difference between the product of the total length and the volume of the rod part 1 is not less than the volume of the inner hole formed by the reverse extrusion of the flange part; Reverse extrusion, the center of the billet f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com