Crossing arrangement method for gas boiler smoke latent heat recovery device

A recovery device, gas boiler technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem that the thermal calculation method is not suitable for the design of waste heat recovery device, there is no clear method for condensing boilers, and the time for condensing boilers is short and other problems, to achieve the effect of improving the operating efficiency of the boiler, improving the operating cycle of the boiler, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

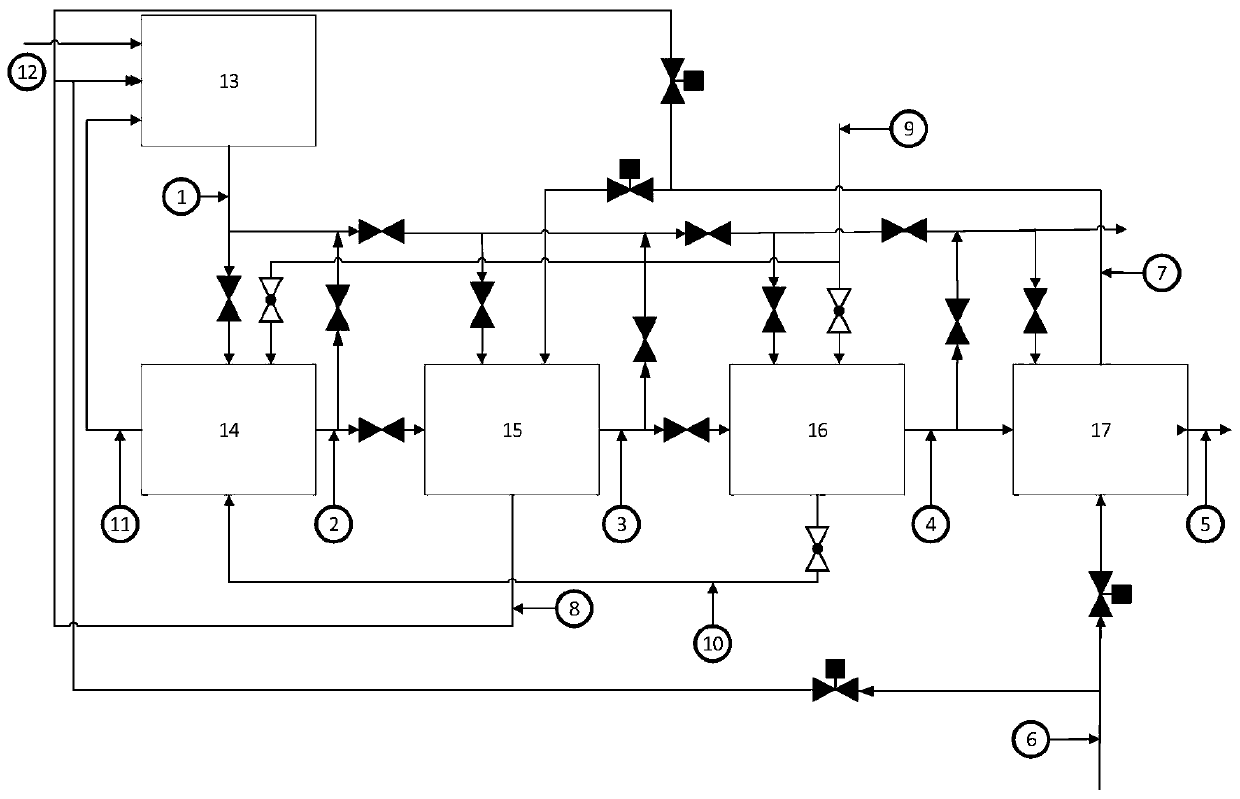

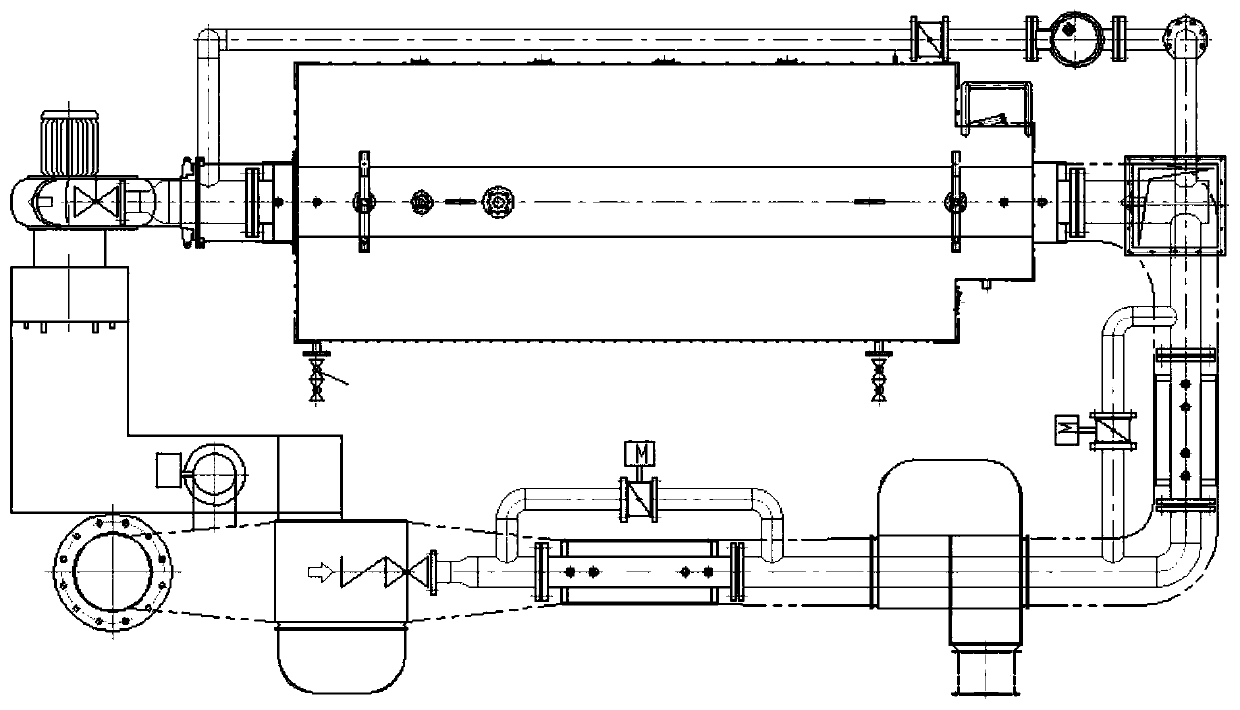

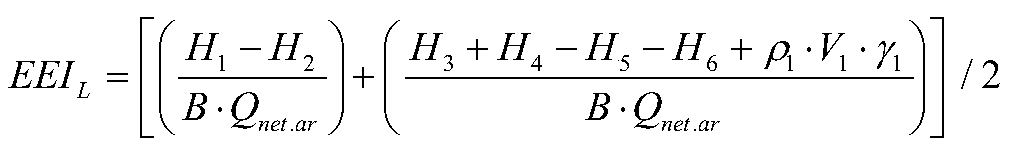

[0026] see Figure 1-2 Describe this embodiment, a gas boiler flue gas latent heat recovery device cross arrangement method, the flue gas outlet of the gas boiler 13 is connected to the latent heat recovery device, and the latent heat recovery device includes multiple condensers and multiple air preheaters , the plurality of condensers and the plurality of air preheaters are arranged crosswise in turn, the flue gas side, the air side and the working fluid side of the latent heat recovery device are measured respectively by sensors, and the plurality of condensers and multi-stages are respectively drawn according to the measurement data The performance curve of each air preheater, the area formed by the performance curves of all condensers and air preheaters is the layout area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com