Production technology for blanking by using a through-hole type universal joint finish forging pot shell capable of moving axially

A technology of axial movement and production process, which is applied in the direction of manufacturing tools, forging/pressing/hammering machinery, couplings, etc., and can solve the problem of large proportion of residual materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

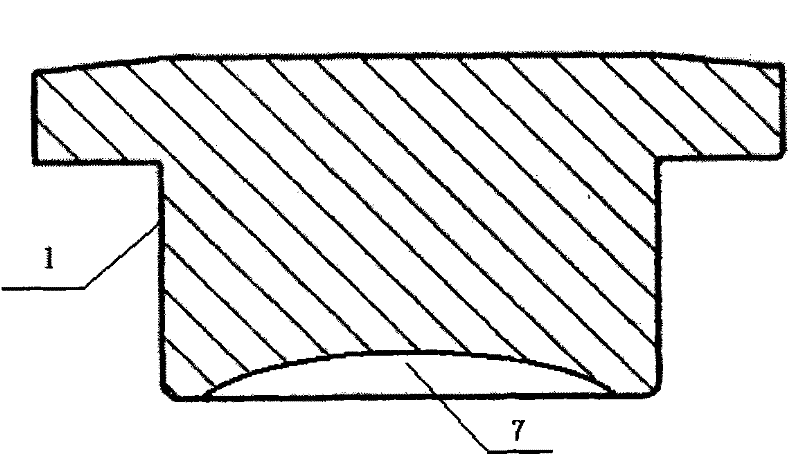

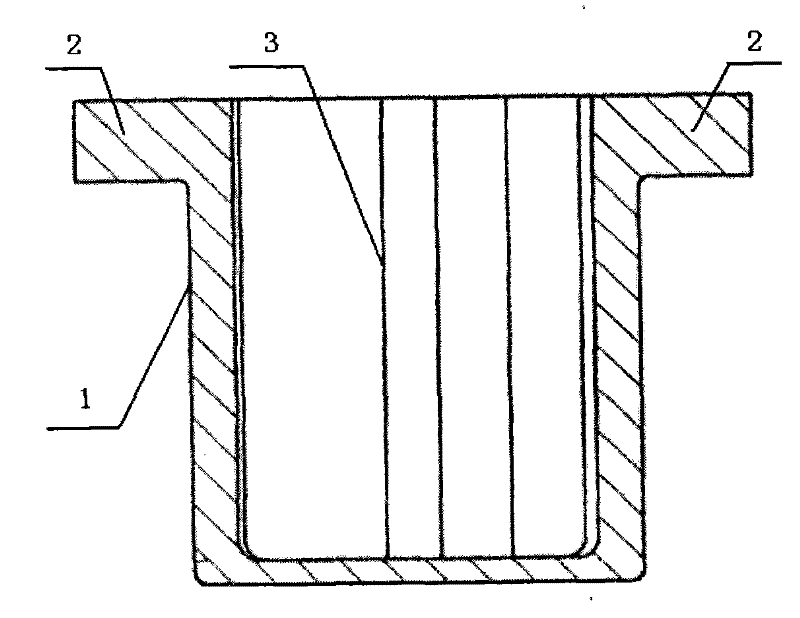

[0016] Embodiment 1: see attached figure 1 with attached figure 2 , a production process for axially movable through-hole universal joint precision forging groove shell blanking, including blanking, heating, and after the metal material is heated after blanking, it is partially upset and extruded in the billet mold , upsetting in a closed cavity to form a rod part 1 and a blank disk part, the rod part 1 is a cylindrical structure, one end is connected with the blank disk part, and the other end is a concave structure, and the concave surface structure The inner cavity 7 is a circular arc surface structure, and the product of the cross-sectional area corresponding to the diameter of the rod 1 and the maximum length of the rod 1 and the volume difference of the rod is not less than the volume of the inner hole formed by the reverse extrusion of the flange , and then put the preformed billet into the cavity of the final forging die, and back-extrude the upset billet at the bill...

Embodiment 2

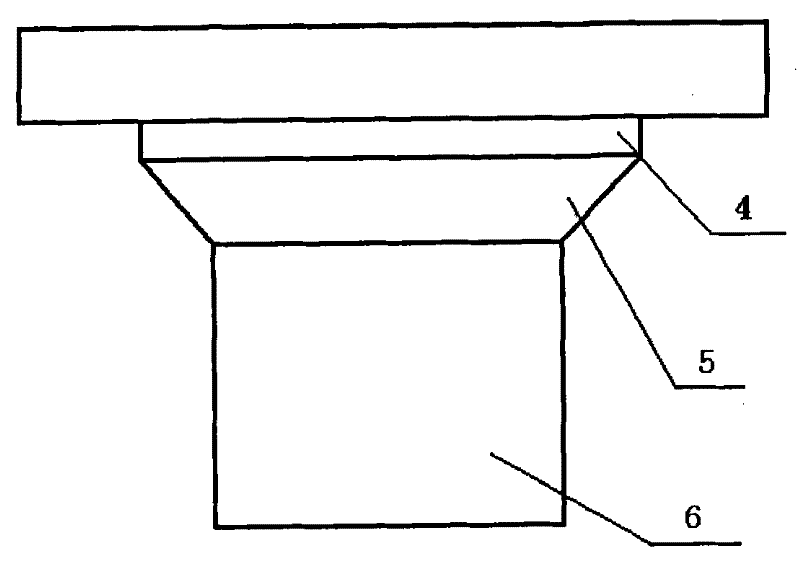

[0017] Embodiment 2: see attached image 3 with attached figure 2 , a production process for axially movable through-hole universal joint precision forging groove shell blanking, including blanking, heating, and after the metal material is heated after blanking, it is partially upset and extruded in the billet mold , upsetting in a closed cavity to form a rod part 1 and a blank disk part, the rod part 1 is divided into three connected sections, the first section 4 and the third section 6 are cylindrical structures with different diameters, the second section The second section 5 is the transition section between the first section and the third section, and the transition section 5 is a solid part formed by a circle whose diameter gradually decreases, and the corresponding cross-sectional area of the diameter of the first section 4 of the rod portion 1 The difference between the product of the total length of the rod 1 and the volume of the rod 1 is not less than the volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com