Battery detection apparatus and battery detection technology

A battery detection and equipment technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of large noise pollution, increased production costs, and heavy workload of workers, and achieve rationalization of production processes, improvement of production efficiency, and savings. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

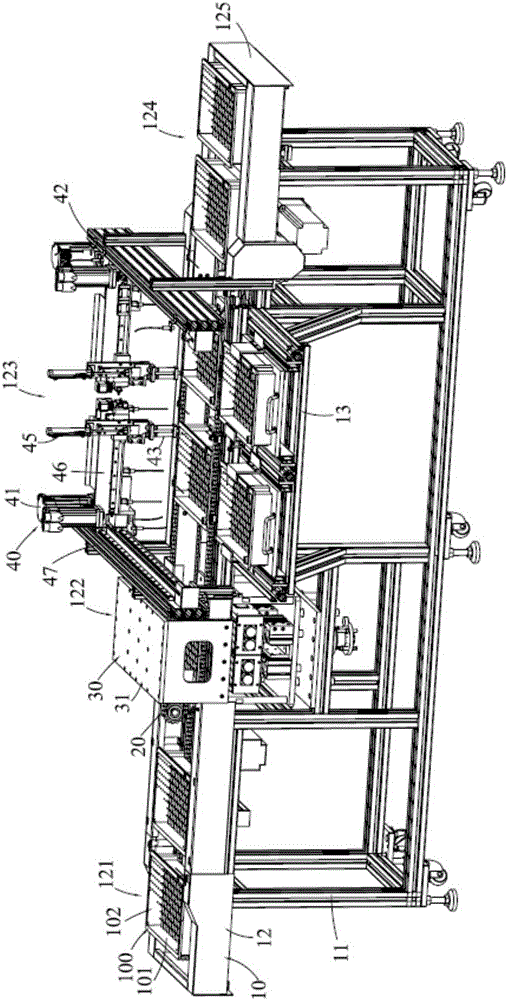

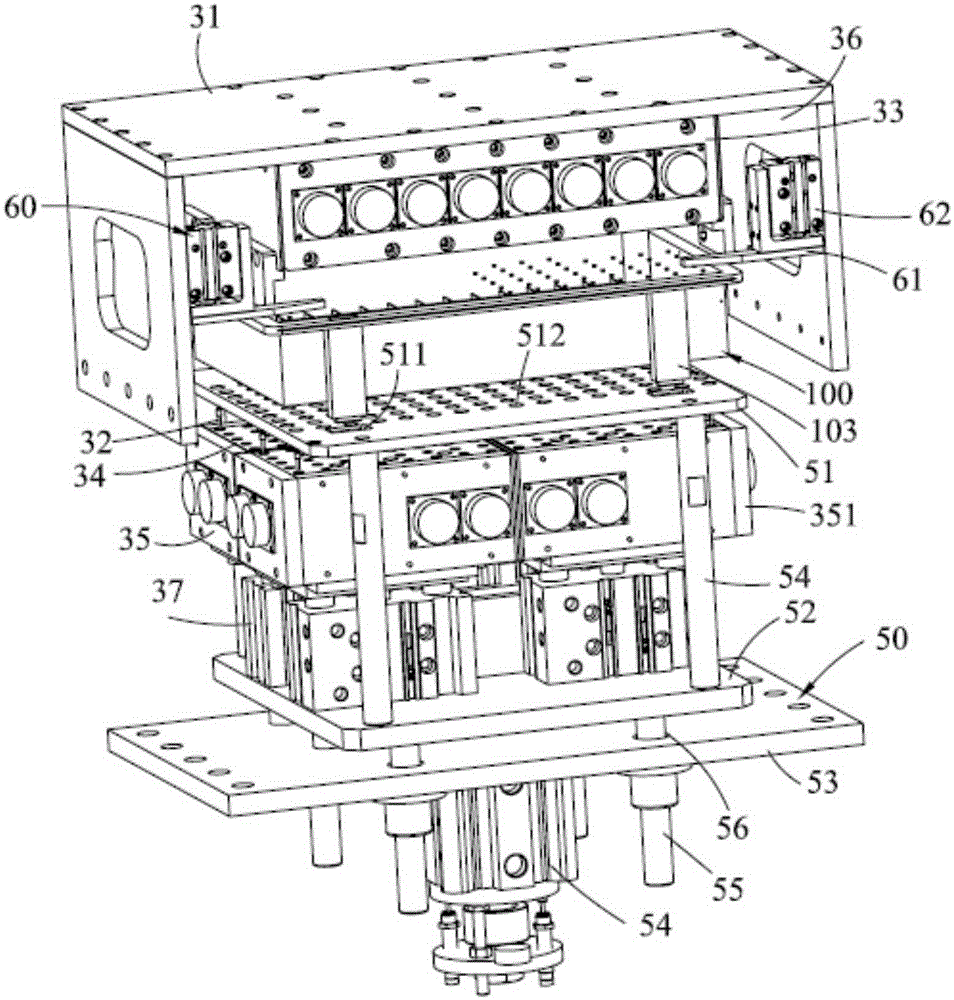

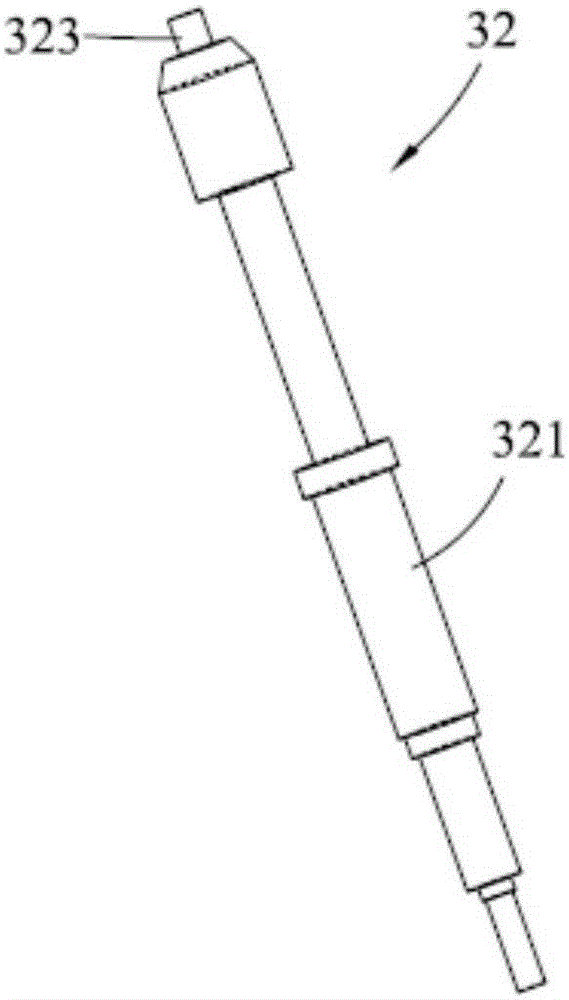

[0027] see Figure 1 to Figure 7 , a battery testing device described in a preferred embodiment of the present invention is used to detect batteries (not numbered) placed in the material box 100, the material box 100 has a top opening 101 and a bottom surface (not shown) oppositely arranged And the side wall 102 extending upwards from the bottom surface, the bottom surface and the side wall 102 surround and form the accommodating cavity (not labeled) for placing the battery, the bottom surface of the cartridge 100 is provided with a bottom opening (not shown), the bottom opening The quantity and position correspond to the quantity and position of the batteries that can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com