Process for de-inking waste newspaper by biologic enzyme

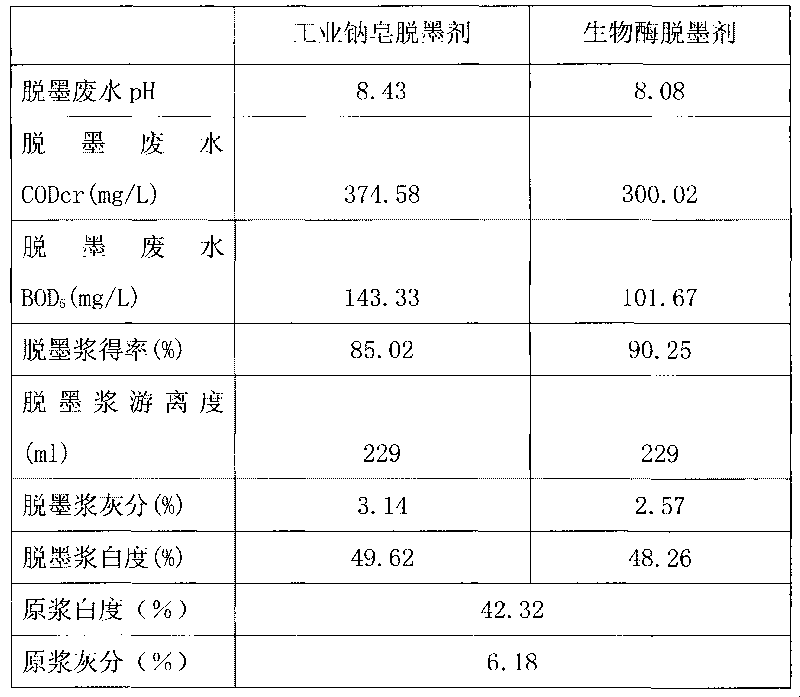

A bio-enzyme and newsprint technology, applied in the field of bio-enzyme deinking process, can solve the problems of high deinking cost and large fiber loss, and achieve the effects of reducing chemical usage, improving pulp yield, and reducing waste water pollution load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The process steps and formula of the present invention are: including deinking agent preparation, high-concentration pulper pulping, flotation separation ink process, wherein the deinking agent formula contains cellulase, lipase, amylase, xylanase, Surfactant, it is characterized in that technological process is:

[0016] ① Preparation of deinking agent: Add one or more of alkaline lipase, amylase, and xylanase to cellulase to make a compound enzyme; the ratio of each component in the compound enzyme is: 2000-10000U cellulose Enzyme, 10000-100000U alkaline lipase, 1000-5000U xylanase and 8000-15000U amylase, and then add 0.05-0.15 kg of surfactant to the compound enzyme of the weight to form a deinking agent;

[0017] Preparation of deinking agent without adding sodium hydroxide and hydrogen peroxide;

[0018] ②Pulping with high-consistency pulper: Add water at 40-60°C to the high-consistency pulper, and put it into waste newspaper and magazine paper (preferably US was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com