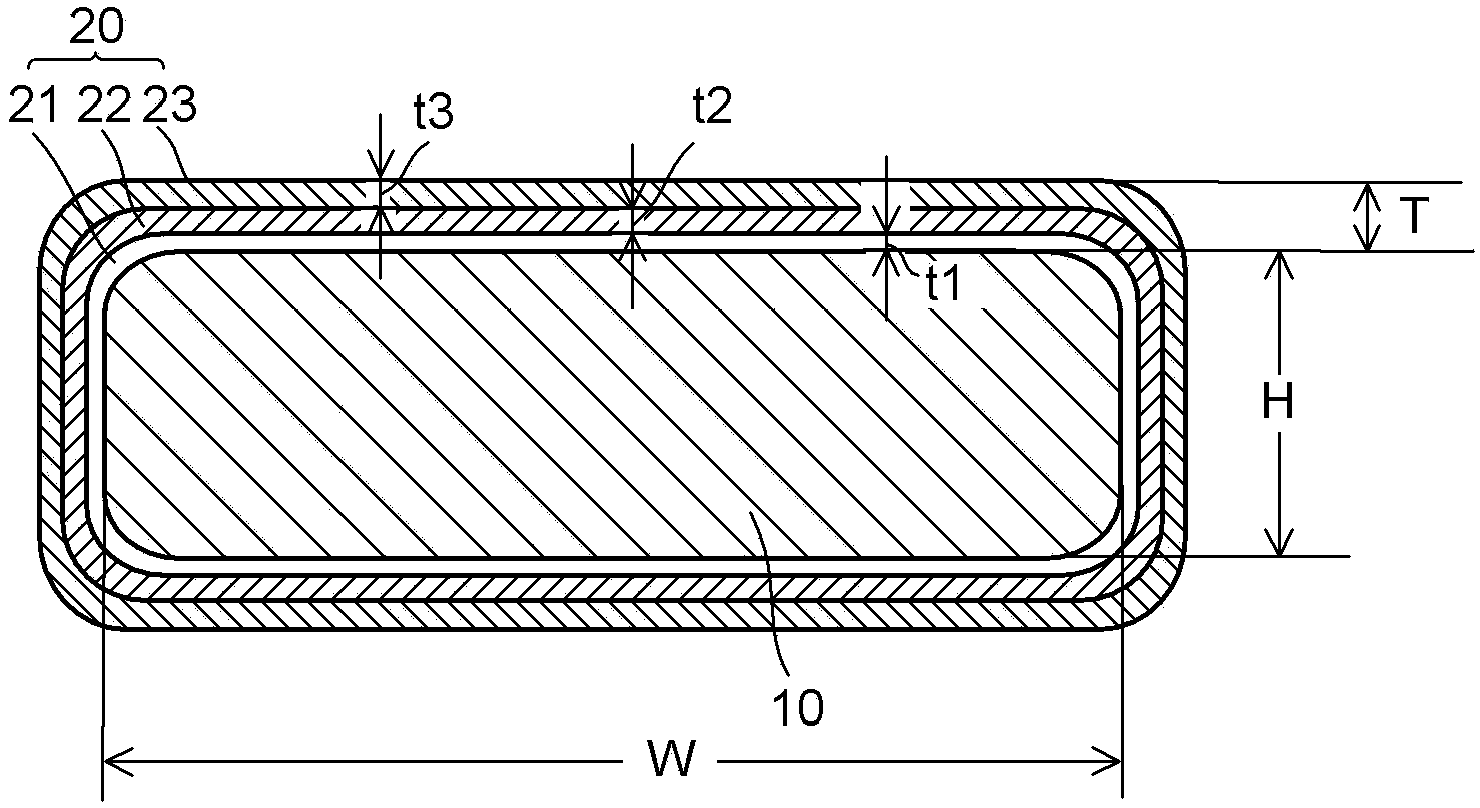

Insulated electric wire

A technology of insulated wires and insulating films, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of insulated wires such as reduced flexibility, difficult to withstand processing, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Hereinafter, the present invention will be specifically described in Examples, but the present invention is not limited to these Examples in any way. In the following description, unless otherwise specified, "part" means "part by mass".

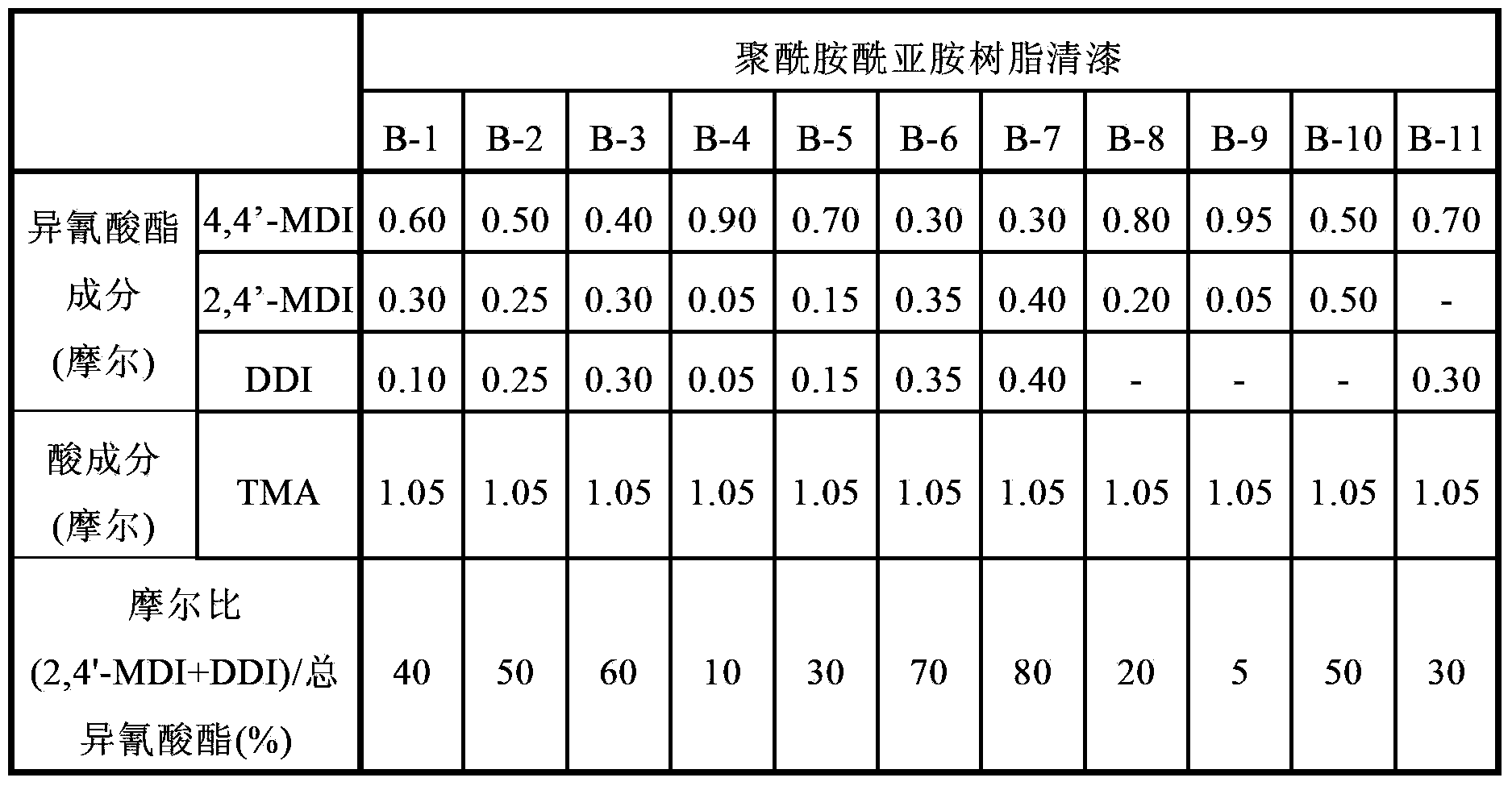

[0038] [Preparation of polyamideimide resin varnish]

preparation Embodiment 1

[0040] In a flask equipped with a stirrer, a nitrogen inflow pipe, and a heating / cooling device, a mixture of 2,4'-MDI and 4,4'-MDI and dimer acid diisocyanate (DDI) were put in as the isocyanate component, and trimellitic anhydride was put in as Acid component. As a solvent, 150 parts of N-methyl-2-pyrrolidone was added to 100 parts of the total amount of the acid and isocyanate components, and the temperature was raised from room temperature to 140°C over 2 hours while stirring under a nitrogen atmosphere. . After reacting at this temperature for 3 hours, dilute with 83 parts of N,N-dimethylformamide (DMF), cool to room temperature, and obtain a polyamide-imide resin varnish (B) with a resin content of 30% by mass. -1).

preparation Embodiment 2~11

[0042] Polyamide-imide resin varnishes (B-2) to (B-11) were obtained in the same manner as in Preparation Example 1, except that the ratio of the isocyanate component was changed to the ratio shown in Table 1.

[0043] [Table 1]

[0044]

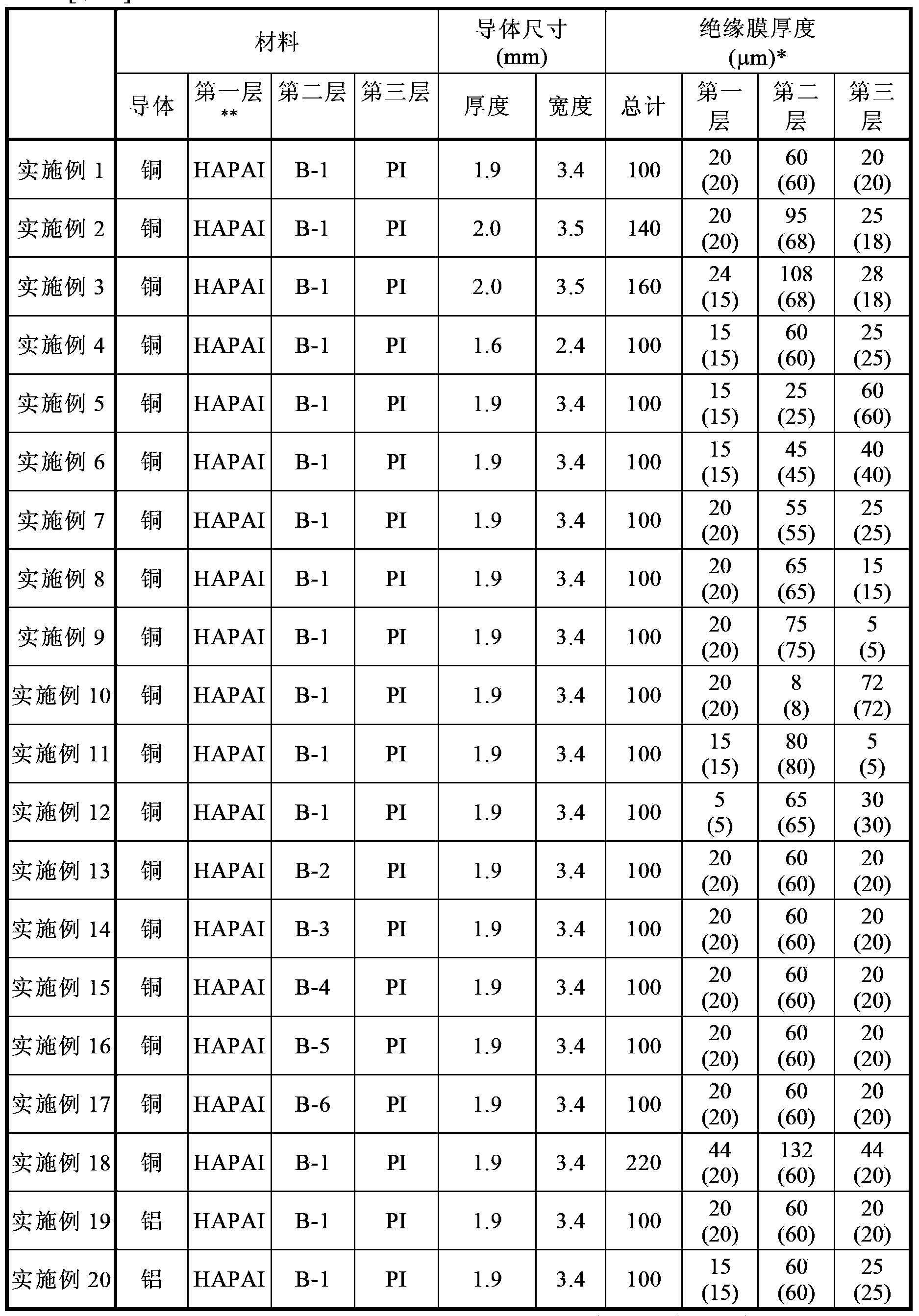

[0045] [Manufacture of insulated wire]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com