Cabo shredding process and equipment

A tobacco stem and shredded technology, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve the problems of cigarette weight, density and suction resistance increase, affect the rolling quality, and the high rate of shredded stems, so as to improve the utilization High efficiency, improved rolling quality and stability, good silk forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

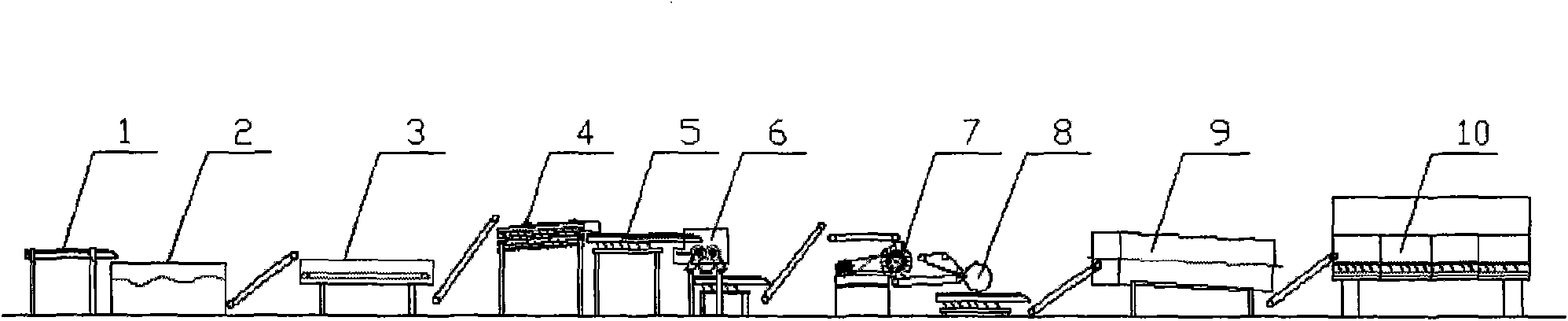

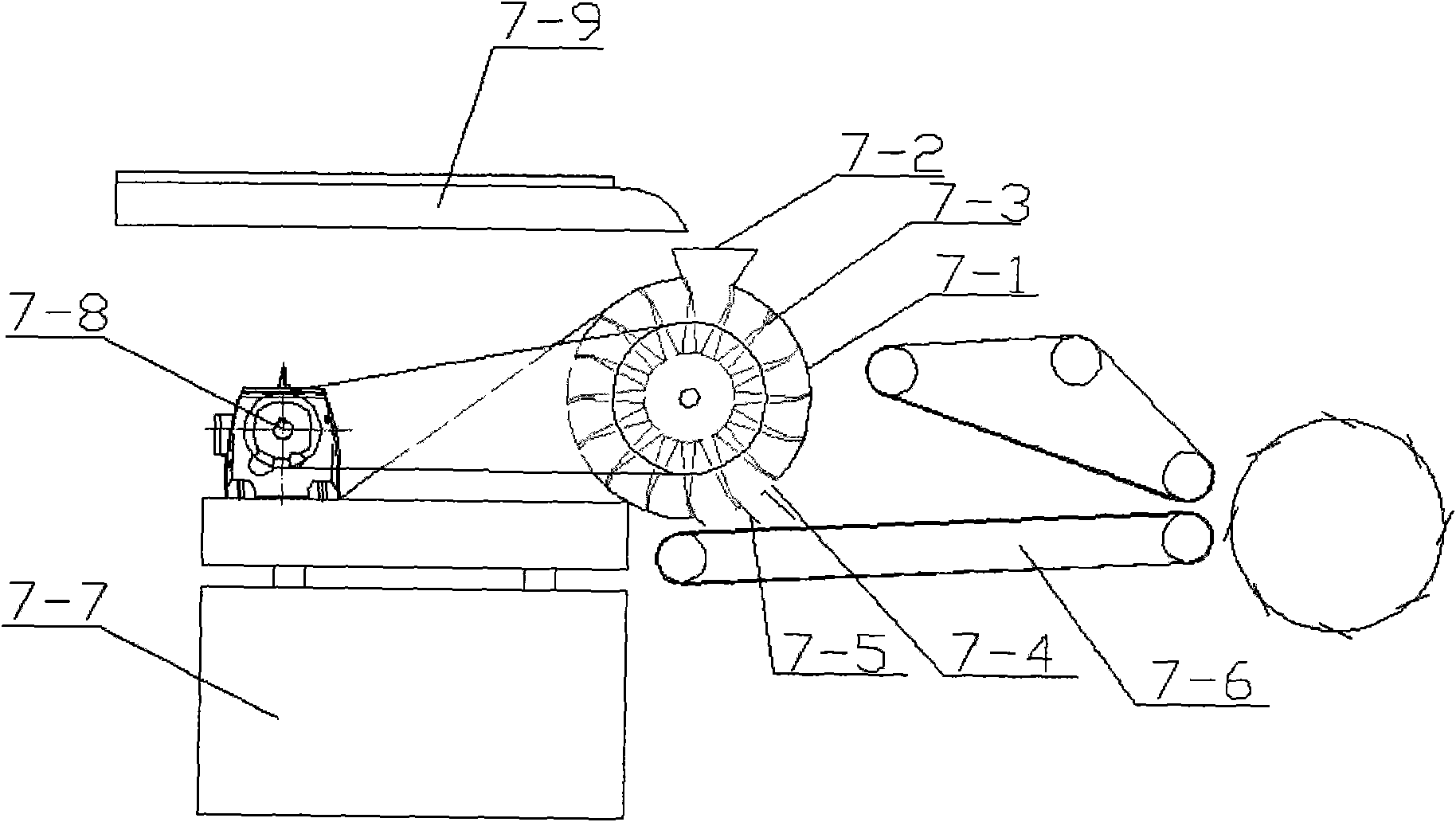

[0030] The present invention will be further described in detail with reference to the accompanying drawings.

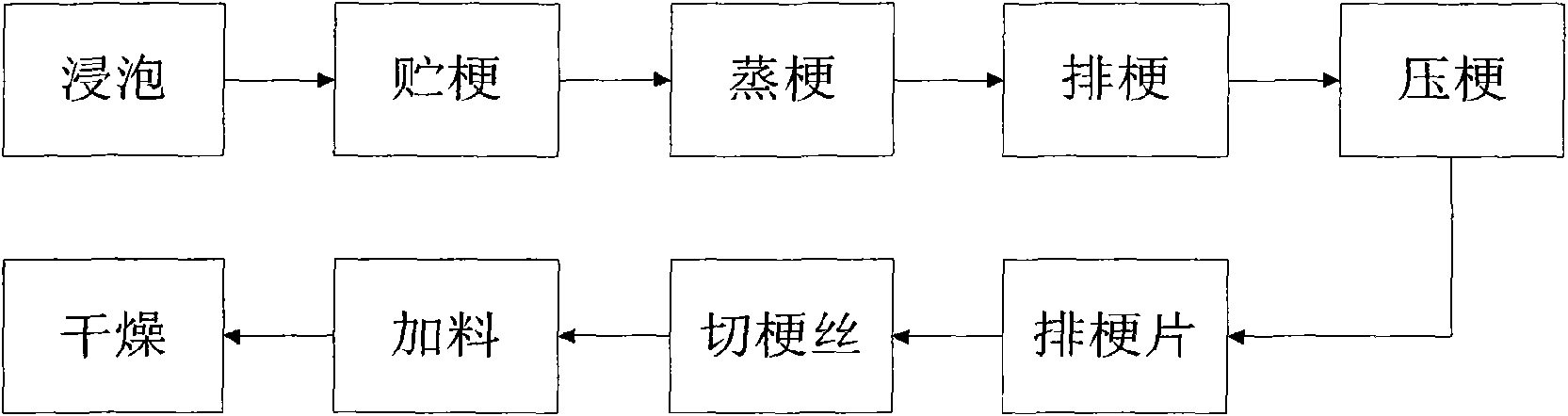

[0031] like figure 1 As shown, the technical process of the tobacco stems of the present invention into shreds is as follows: after the quantitatively fed tobacco stems are sieved through the screening process to remove the broken stems, in order to meet the needs of the subsequent thinning process of the stem pressing process, the tobacco stems are sent into a container The immersion device of tap water carries out immersion treatment at normal temperature, and immersion time is 1-3 hour, and the tobacco stem fully absorbs moisture through long-time immersion, has also been removed dust and metal and non-metallic sundry on the surface of tobacco stem simultaneously; In order to further Improve the moisture uniformity of the tobacco stems, transport the soaked tobacco stems to the storage cabinet for storage, and the storage time is 2-4 hours; the tobacco stems after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com