Loosening and dampening method of tobacco leaves under condition of low intensity

A loose moisture regain, low-strength technology, used in tobacco, tobacco preparation, tobacco processing and other directions, can solve the problems of high shredding rate, loss of aroma quality and aroma quantity, and high shredding rate of tobacco leaves, and achieve high moisture and temperature uniformity of tobacco leaves. , The effect of increasing the processing resistance and improving the loosening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

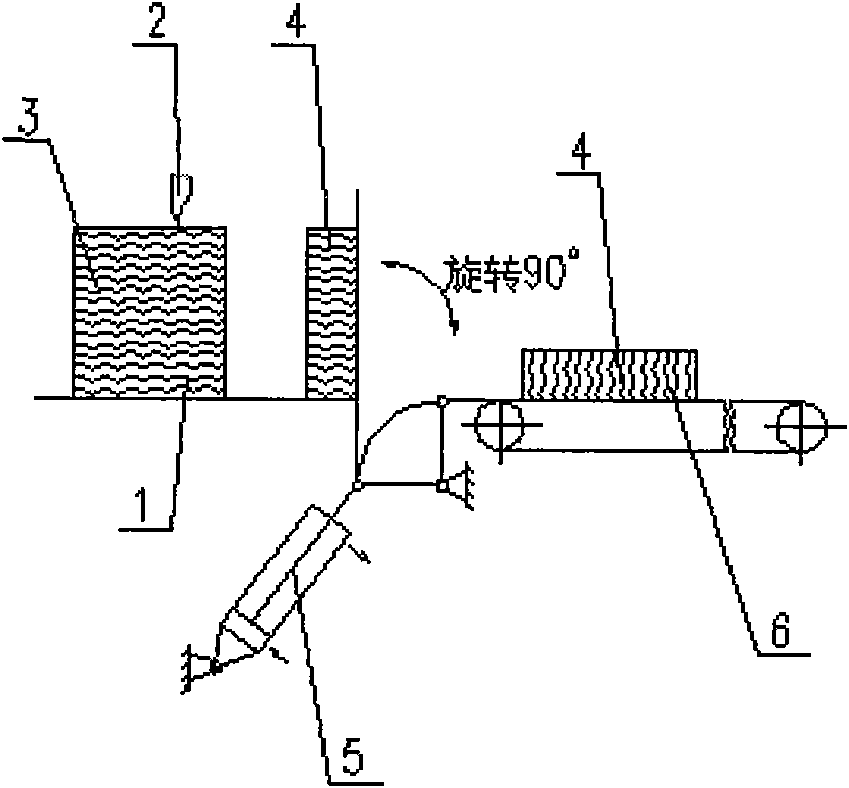

[0036] Such as figure 1 As shown, the unboxed cigarette bale was cut into 1 slice, and the slice direction was perpendicular to the layering direction of the tobacco leaves in the pack into 3 slices. The slices were cut with multi-knife thin cuts, and the slice thickness of the cut tobacco block was 80 mm. After cutting, the cigarette block 4 is turned over 90° by the traction of the box-turning mechanism 5 and then placed on the moving mesh belt (or mesh plate) 6 of the tunnel type pre-increasing moisture regain loosening machine. The layering direction of the cigarette block 4 is perpendicular to the moving mesh belt ( Or stencil) 6 sides. After cutting, the cigarette block adopts a stable release mechanism (that is, the box turning mechanism), so that the cigarette block can be placed neatly on the downstream equipment, and the posture meets the requirements.

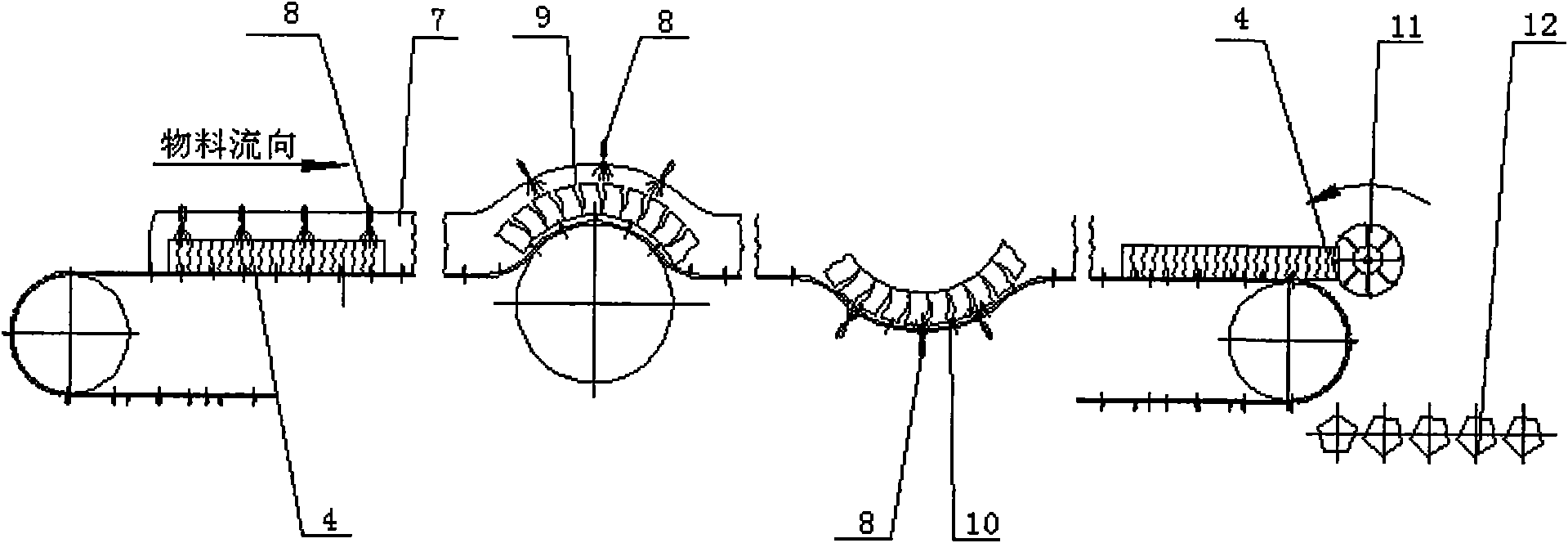

[0037] Such as figure 2 As shown, the cut cigarette block 4 is conveyed through the straight tunnel 7 of the tu...

Embodiment 2

[0046] Such as figure 1 As shown, the unboxed cigarette bale was cut into 1 slice, and the slice direction was perpendicular to the layering direction of the tobacco leaves in the pack into 3 slices. The slices were cut with multi-knife thin slices, and the slice thickness of the cut tobacco block was 150 mm. After cutting, the cigarette block 4 is turned over 90° by the traction of the box-turning mechanism 5 and then placed on the moving mesh belt (or mesh plate) 6 of the tunnel type pre-increasing moisture regain loosening machine. The layering direction of the cigarette block 4 is perpendicular to the moving mesh belt ( Or stencil) 6 sides. After cutting, the cigarette block adopts a stable release mechanism (that is, the box turning mechanism), so that the cigarette block can be placed neatly on the downstream equipment, and the posture meets the requirements.

[0047] Such as figure 2 As shown, the cut cigarette block 4 is conveyed through the straight tunnel 7 of the...

Embodiment 3

[0056] Such as figure 1As shown, the unboxed cigarette bale was cut into 1 slice, and the slice direction was perpendicular to the layering direction of the tobacco leaves in the pack into 3 slices. The slices were cut in a multi-knife thin-cut method, and the slice thickness of the cut tobacco block was 220 mm. After cutting, the cigarette block 4 is turned over 90° by the traction of the box-turning mechanism 5 and then placed on the moving mesh belt (or mesh plate) 6 of the tunnel type pre-increasing moisture regain loosening machine. The layering direction of the cigarette block 4 is perpendicular to the moving mesh belt ( Or stencil) 6 sides. After cutting, the cigarette block adopts a stable release mechanism (that is, the box turning mechanism), so that the cigarette block can be placed neatly on the downstream equipment, and the posture meets the requirements.

[0057] Such as figure 2 As shown, the cut cigarette block 4 is conveyed through the straight tunnel 7 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com