Method for preparing reconstructed tobacco-leaf cigarette paper by replacing part of wood pulp with bamboo pulp

A technology for recombining tobacco leaves and cigarette paper, which is applied in the fields of pulping, papermaking, and paper coating with inorganic alkali, which can solve the problems of woody gas weight and affecting the quality of recombined tobacco leaves and cigarette paper, so as to achieve the fragrance of smoke and improve the quality of smoke Quality, physical performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

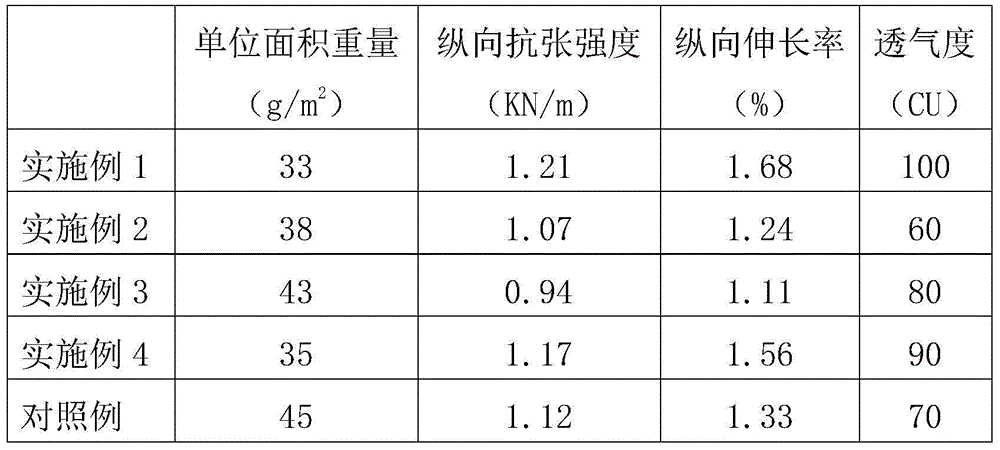

Embodiment 1

[0023] A method for preparing recombined tobacco leaf cigarette paper, comprising the following steps:

[0024] (1) Adding 4 times of NaOH aqueous solution with a weight concentration of 10% by weight to the bamboo chip raw material, and cooking for 2.5 hours at a temperature of 155° C. to obtain the original bamboo pulp;

[0025] (2) beating the former pulp of bamboo pulp to 700SR to obtain bamboo pulp slurry;

[0026] (3) beating commercial wood pulp to 700SR to obtain wood pulp slurry;

[0027] (4) the bamboo pulp slurry is blended in the wood pulp slurry according to a weight ratio of 40%, and copied into cigarette paper base paper;

[0028] (5) Prepare the coating solution and apply it on the cigarette paper base paper, the coating amount is 12g / m 2 , after drying.

[0029] The preparation method of the coating liquid is as follows: take the following raw materials according to the weight ratio: 10% of tobacco extract, 1% of potassium bicarbonate, 10% of food coloring,...

Embodiment 2

[0031] A method for preparing recombined tobacco leaf cigarette paper, comprising the following steps:

[0032] (1) Adding 3 times the NaOH aqueous solution with a weight concentration of 15% by weight to the bamboo chip raw material, cooking for 3 hours at a temperature of 150° C. to obtain the original bamboo pulp;

[0033] (2) beating the former pulp of bamboo pulp to 500SR to obtain bamboo pulp slurry;

[0034] (3) beating commercial wood pulp to 500SR to obtain wood pulp slurry;

[0035] (4) the bamboo pulp slurry is blended in the wood pulp slurry according to a weight ratio of 10%, and copied into cigarette paper base paper;

[0036] (5) Prepare the coating solution and apply it on the cigarette paper base paper, the coating amount is 3g / m 2 , after drying.

[0037] The preparation method of the coating liquid is as follows: take the following raw materials according to the weight ratio: 5% of tobacco extract, 2% of potassium chloride, 15% of food coloring, 15% of sp...

Embodiment 3

[0039] A method for preparing recombined tobacco leaf cigarette paper, comprising the following steps:

[0040] (1) Adding 8 times the weight concentration of 5% KOH aqueous solution by weight to the bamboo chip raw material, and cooking it for 2 hours at a temperature of 170° C. to obtain the original bamboo pulp;

[0041] (2) beating the former pulp of bamboo pulp to 900SR to obtain bamboo pulp slurry;

[0042] (3) beating commercial wood pulp to 900SR to obtain wood pulp slurry;

[0043] (4) the bamboo pulp slurry is blended in the wood pulp slurry according to a weight ratio of 90%, and copied into cigarette paper base paper;

[0044] (5) Prepare the coating solution and apply it on the cigarette paper base paper, the coating amount is 20g / m 2 , after drying.

[0045] The preparation method of the coating liquid is: take the following raw materials according to weight ratio: 15% of tobacco extract, 1.5% of potassium sulfate, 5% of food coloring, 5% of spices and the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com