Method for producing multi-grain liquor of Luzhou-flavor and Maotai-flavor

A production method and thick sauce technology, which is applied in the production of liquor products, can solve the problems of harmonization of liquor body and poor fullness, unstable quality of liquor products, etc., and achieve the effects of long aftertaste, full body and obvious sauce aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

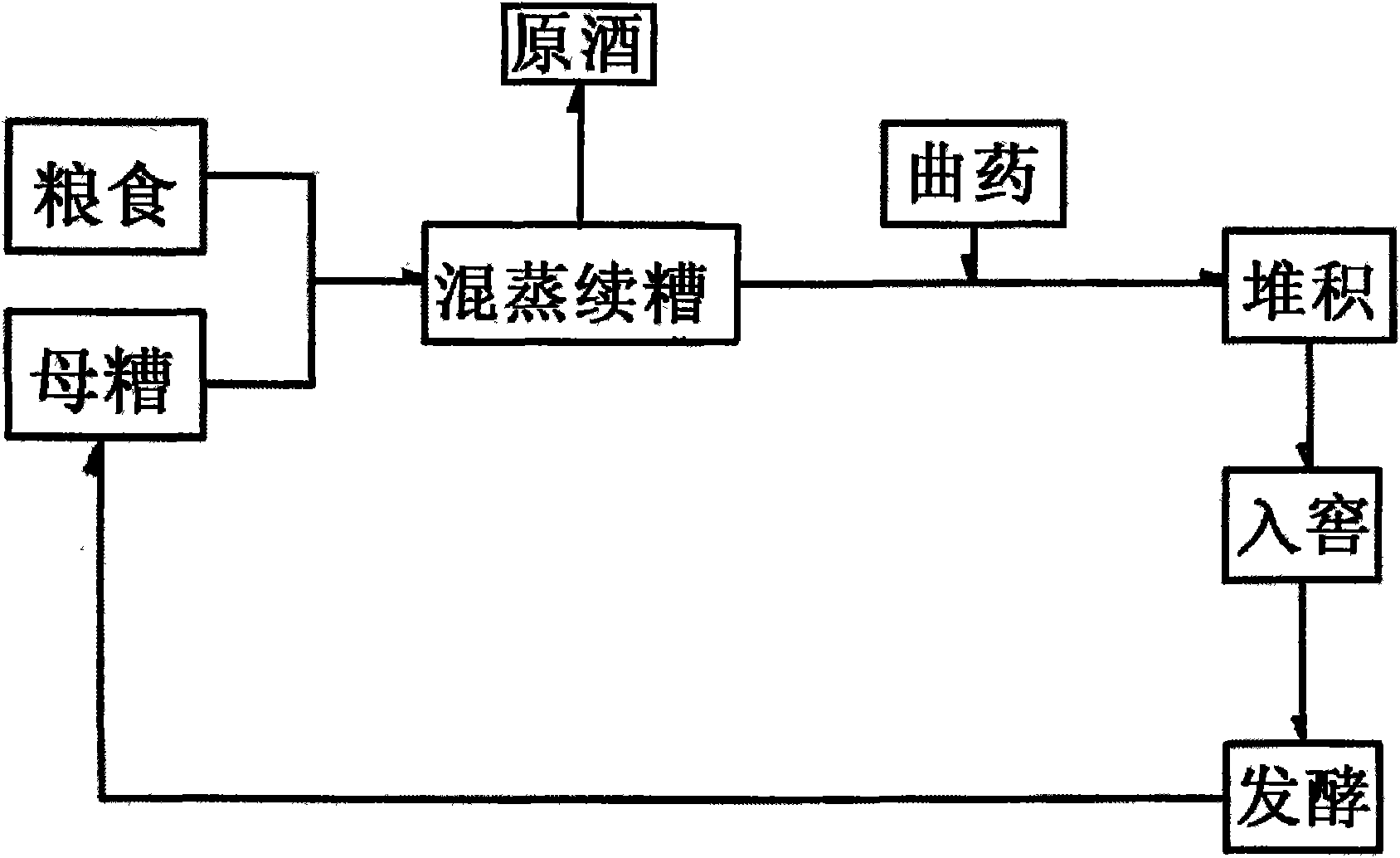

Method used

Image

Examples

Embodiment 1

[0021] The hot season (hot season is from May to October) embodiment of the present invention is that the saccharification starter used is a relatively high temperature packaged koji (or medium-high temperature Daqu, During its production process, the highest product temperature of koji unstrained spirits is 50-63°C) and high-temperature wrapping koji (the highest product temperature of koji unstrained spirits during its production process is 64-72°C), according to the weight ratio, high temperature wrapping koji: high temperature Baobaoqu = 1:0.3 mixed use.

[0022] The grain raw materials used are sorghum, rice, corn, wheat, and glutinous rice, and the proportions of the total weight are 36% of sorghum, 22% of rice, 8% of corn, 16% of wheat, and 18% of glutinous rice. They are mixed and used; the use of mixed grain raw materials The amount is 200Kg / retort (retort: the diameter of retort barrel during traditional distillation is 1.8m×height 0.8m); the ratio of mixed grain t...

Embodiment 2

[0026] The cold season (cool season is from November to April) embodiment of the present invention is that the saccharification starter used is a relatively high temperature bag koji (or medium-high temperature Daqu, During the production process, the highest product temperature of koji unstrained spirits is 50-63°C) and high-temperature wrapping koji (the highest product temperature of koji unstrained spirits during the production process is 64-72°C), according to the weight ratio, high temperature wrapping koji: high temperature Baobaoqu = 1:0.7 mixed use.

[0027] The grain raw materials used are sorghum, rice, corn, wheat, and glutinous rice mixed according to respective proportions of 36%, 22%, 8%, 16%, and 18%; The diameter of the retort during traditional distillation is 1.8m × height 0.8m); the ratio of mixed grain to mother's grain (normal grains that have not been distilled for the last round of fermentation) is 1:3.5; the ratio of grain to mother's grain The mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com