Absorbent composition for decreasing nicotine in tobacco extract and absorption method thereof

A technology of tobacco extraction liquid and adsorbent, which is applied in the field of tobacco industry to achieve the effects of clean aftertaste, wide sources and elegant smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method for reducing nicotine in reconstituted tobacco leaves with a porous adsorbent, comprising the following steps:

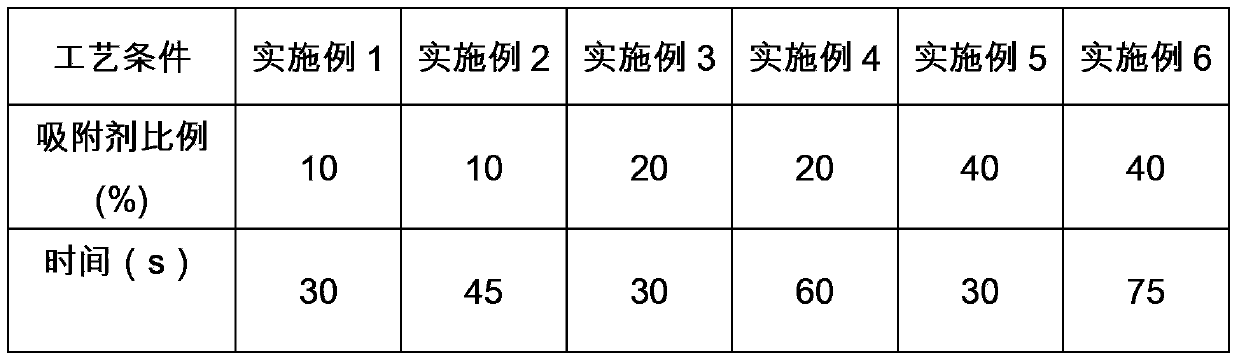

[0031] A: Mix activated carbon, bamboo charcoal, zeolite, starch, and chitosan, and add them to the filter bag of the filter at a ratio of 10% or 15% or 20% or 30% or 40% or 45%;

[0032] B: Tobacco powder extract with a concentration of 1.042 or tobacco stem extract with a concentration of 1.085 was mixed with 100 liters of extract in 1m 3 The flow rate of / h flows into the filter, and the adsorbent is added to the filter bag by 10 kg or 15 kg or 20 kg or 30 kg or 40 kg or 45 kg;

[0033] C: adjust the flow rate of the filter according to the interaction time of a certain volume of tobacco powder or tobacco stem extract with the adsorbent for 30 seconds or 45 seconds or 60 seconds or 75 seconds;

[0034] D: Concentrate the extract that has been subjected to the action of the adsorbent according to the original vacuum concentration proce...

Embodiment 7

[0037] 1. Mix 30 parts of activated carbon, 30 parts of bamboo charcoal, 10 parts of zeolite, 20 parts of starch and 10 parts of chitosan evenly, with a total of 40 kg, and add them to the filter bag of the filter;

[0038] 2. Add 100 liters of tobacco powder extract to the filter at a temperature of 50°C, and the action time is 30 seconds, and adjust the flow rate of the filter to 1m 3 / h;

[0039] 3. Collect the tobacco powder extract that has been subjected to the action of the adsorbent, concentrate it in a vacuum to form a concentrate, mix the concentrate with the normal tobacco stem concentrate (without adsorption) at a ratio of 50:50, add certain auxiliary materials, and make a coating solution,

[0040] 4. The reconstituted tobacco leaf has a clean aftertaste and elegant smoke after the sensory smoking quality evaluation, reduces the harm of nicotine (nicotine) to human health, and enhances the adjustability and controllability of nicotine in the chemical indicators o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com