Control method for realizing sustained release of smoke of heating non-combustion tobacco products

A heat-not-burn, control method technology, applied in tobacco, smoker's products, applications, etc., can solve problems such as affecting the use effect of electromagnetic induction heating devices, lag in temperature measurement of induction heating materials, and strict heating conditions. Endurance ability, reduce side flow flue gas spillover, release sufficient and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

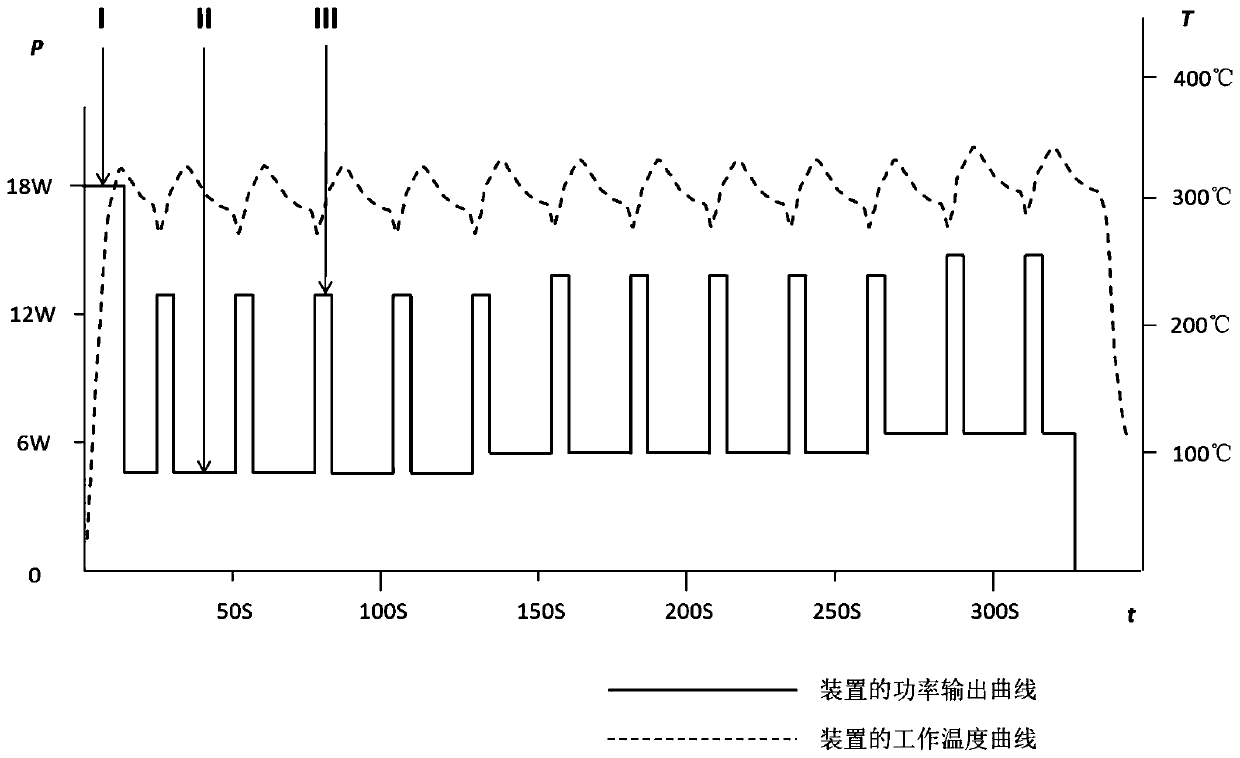

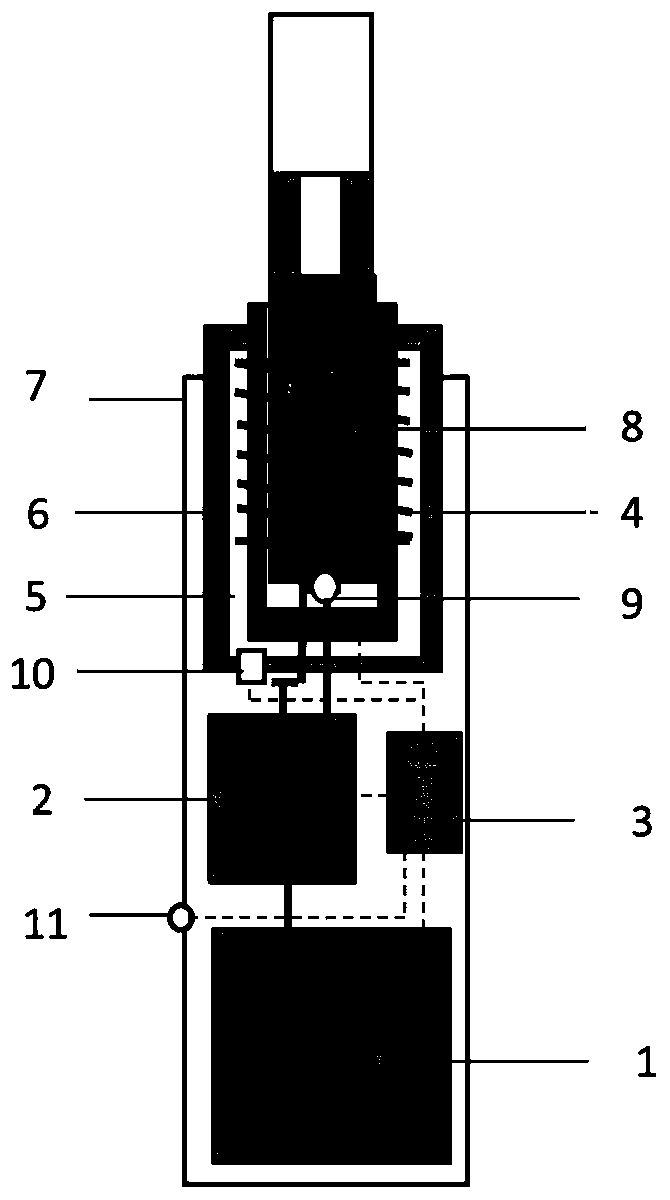

[0073] Example 1: Control of sustained release of smoke from heat-not-burn tobacco products

[0074] The implementation steps of this embodiment are as follows:

[0075] This example uses the attached figure 2 The heating appliance described, wherein the DC battery power supply 1 is a lithium battery; the high-frequency oscillation circuit 2 is a MOSFET gold-oxide-semiconductor field-effect transistor; the control circuit 3 is sold by Dongguan Daixun Electronic Technology Co., Ltd. under the trade name NRF51822-QFAB microprocessor chip The product; the air pressure sensor 9 is a product sold by Shenzhen Yinsun Technology Co., Ltd. under the trade name Mitou Switch; the magnetic induction coil 4 is an electromagnetic induction coil with a twist distance of 0.4mm, a length of 1800mm, a diameter of 12mm, and a working voltage of 2V; heating Cavity 5 is a cylindrical cavity with an inner diameter of 6 mm, a length of 32 mm, and a wall thickness of 2.0 mm; the electromagnetic hea...

Embodiment 2

[0082] Example 2: Control of sustained release of smoke from heat-not-burn tobacco products

[0083] The implementation of this embodiment is the same as that of Example 1, except that the DC battery power supply 1 is a lithium-ion battery; the high-frequency oscillation circuit 2 is an IGBT insulated gate bipolar transistor; the temperature sensor 10 is made by Ninghai Huashen Electronics Co., Ltd. The resistive temperature sensor sold by the company under the trade name HS-T6 resistive high-precision temperature sensor;

[0084] In the preheating stage I, the heating device outputs 12W power for 25s to heat the tobacco material to a temperature of 316°C to release sufficient smoke; the heating device regulates the operating voltage of the high-frequency oscillation circuit 2 through the control circuit 3 to 9V realizes the adjustment to output power; At the end of preheating stage 1, the smoking signal prompter 11 sold by Shenzhen Juhong Optoelectronics Co., Ltd. under the t...

Embodiment 3

[0089] Example 3: Control of sustained release of smoke from heat-not-burn tobacco products

[0090] The implementation of this embodiment is the same as that of Example 1, except that the DC battery power supply 1 is a nickel-cadmium battery; the high-frequency oscillation circuit 2 is an IGFET insulated gate field-effect transistor; the temperature sensor 10 is made by Dongguan Meixin Automation Technology Co., Ltd. Co., Ltd. sells thermocouple temperature sensors under the trade name Thermistor;

[0091] In the preheating stage I, the heating device outputs 18W power for 20s to heat the tobacco material to a temperature of 348°C to release sufficient smoke; the heating device regulates the operating voltage of the high-frequency oscillation circuit 2 to 18V; at the end of the preheating phase I, the mechanical vibration smoking signal prompter is the smoking signal prompter 11 sold by Huizhou Liborite Electromechanical Co., Ltd. under the trade name Micro Vibration Motor to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com