Mixed type tobacco molecular distillation light component electronic tobacco liquid and preparation method thereof

A technology of molecular distillation and e-cigarette liquid, which is applied in the field of e-cigarettes, can solve the problems of lack of tobacco flavor characteristics, weak tobacco flavor characteristics, and inability to improve smokers' throat and lung discomfort, so as to increase throat comfort and satisfy smoking Demand, the effect of sufficient aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

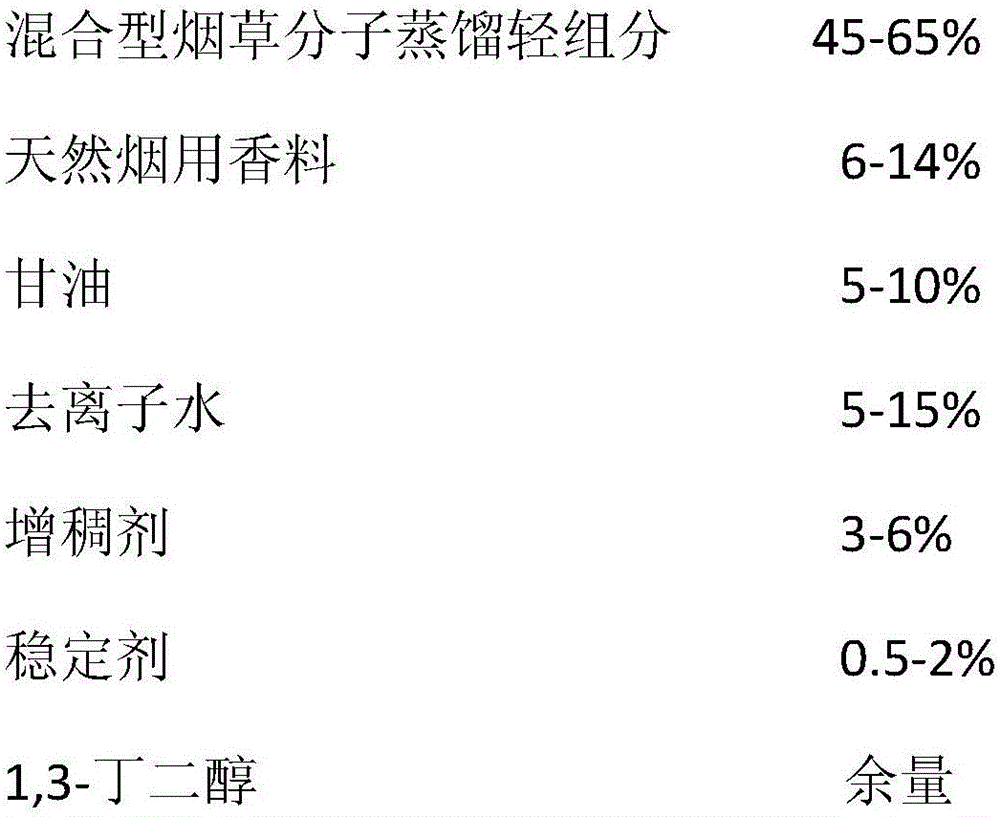

[0028] Example 1, a hybrid tobacco molecular distillation light component e-cigarette liquid is prepared by the following steps:

[0029] (1) Preparation of mixed tobacco molecular distillation light components:

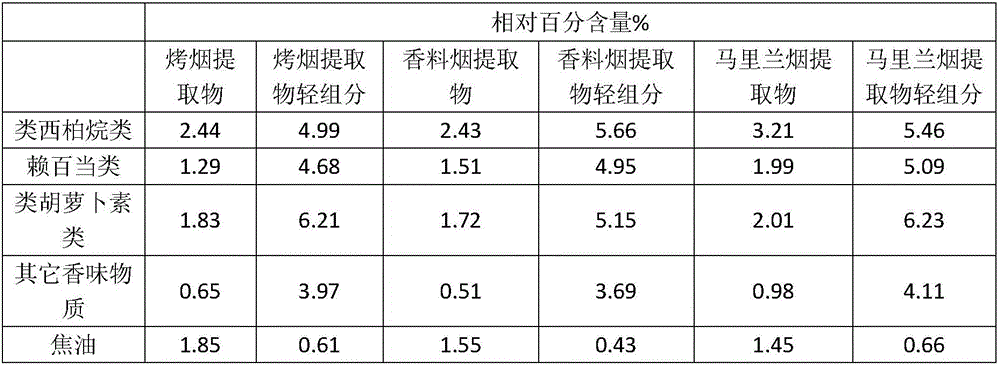

[0030] a. Crush 10kg of flue-cured tobacco, add 100kg of ethanol with a concentration of 50% and stir for extraction for 2 hours, the extraction temperature is 60°C; after filtering the extract, take out the filtrate and concentrate it in vacuum at 50°C to obtain the flue-cured tobacco extract, the flue-cured tobacco extract is relatively water The density is 1.150~1.170;

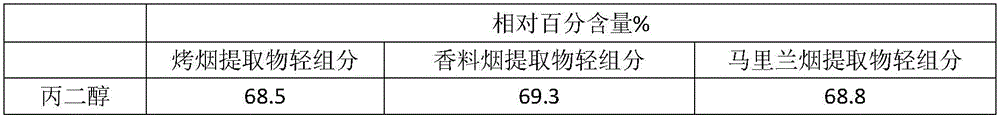

[0031] b. Molecular distillation of the obtained flue-cured tobacco extract: Weigh 1000 g of the flue-cured tobacco extract prepared in step a, add 200 g of propylene glycol, mix well and add it to a molecular distillation apparatus for distillation: the molecular distillation is preliminarily determined to prepare the flue-cured tobacco extract The optimal conditions for the light components of ...

Embodiment 2

[0037] Example 2, a hybrid tobacco molecular distillation light component e-cigarette liquid is prepared by the following steps:

[0038](1) Preparation of mixed tobacco molecular distillation light components:

[0039] a. Crush 10kg of flue-cured tobacco, add 100kg of ethanol with a concentration of 50% and stir for 2.5h to extract at a temperature of 70°C; after filtering the extract, take out the filtrate and concentrate it in vacuum at 50°C to obtain the flue-cured tobacco extract, which is relatively The density of water is 1.150~1.170;

[0040] b. Molecular distillation of the obtained flue-cured tobacco extract: Weigh 1000 g of the flue-cured tobacco extract prepared in step a, add 200 g of propylene glycol, mix well, and add it to a molecular distillation apparatus for distillation: Preliminary determination of molecular distillation to prepare flue-cured tobacco extract The optimal conditions for the light components of the product are: the distillation temperature i...

Embodiment 3

[0046] Example 3, a hybrid tobacco molecular distillation light component e-cigarette liquid is prepared by the following steps:

[0047] (1) Preparation of mixed tobacco molecular distillation light components:

[0048] a. Grind 10kg of flue-cured tobacco, add 100kg of 50% ethanol and stir for extraction for 3 hours, the extraction temperature is 65°C; after filtering the extract, take out the filtrate and concentrate it in vacuum at 50°C to obtain the flue-cured tobacco extract, which is relatively water The density is 1.150~1.170;

[0049] b. Molecular distillation of the obtained flue-cured tobacco extract: Weigh 1000 g of the flue-cured tobacco extract prepared in step a, add 200 g of propylene glycol, mix well, and add it to a molecular distillation apparatus for distillation: Preliminary determination of molecular distillation to prepare flue-cured tobacco extract The optimal conditions for the light components of the product are: the distillation temperature is 57°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com