Method for producing cooking wine by replacing part of rice with waste yellow wine lees

A technology for discarding grains of rice wine and rice, applied in the functions, applications, food ingredients and other directions of food ingredients, can solve the problems of limiting the improvement of rice wine benefits, not attracting too much attention, polluting the ecological environment, etc., to achieve good color, protection The effect of environment and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

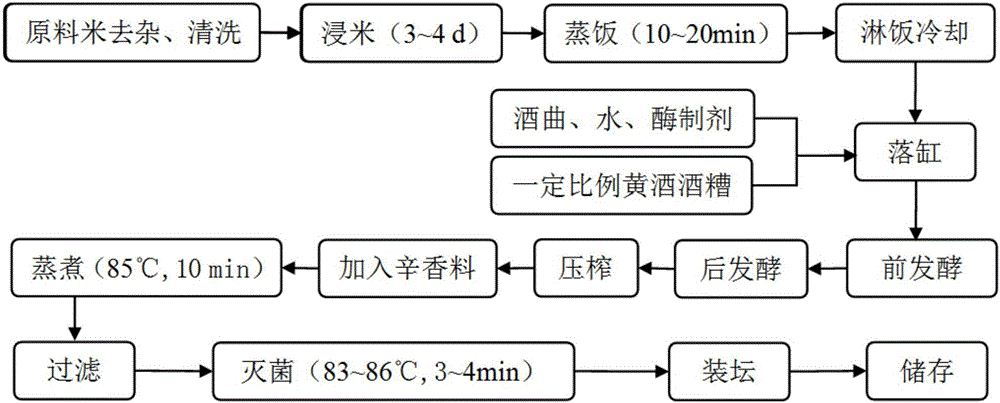

[0025] (1) Rice soaking: remove impurities from the japonica rice, weigh, wash, soak in water for 3-4 days, and soak the rice in water for 30cm.

[0026] (2) Steamed rice: Transfer to a steamer and cook for 10-20 minutes.

[0027] (3) Drenching the rice to cool down: pour cold water (10-30°C) over the rice until the rice cools to room temperature, drain the remaining water after pouring the rice, and transfer the rice to the brewing tank.

[0028] (4) Adding distiller's koji: Add the raw materials rice, water, wheat koji and distiller's mother into the brewing tank, and mix well. The mass ratio of raw material rice to water, wheat koji and distiller's mother is 1000:950:160:85.

[0029] (5) Pre-fermentation: The fermentation temperature is controlled at 28-32°C, the time is 4-12 days, and the rake is opened every 6-8 hours.

[0030] (6) Post-fermentation: transfer the pre-fermented product to the post-fermentation tank for 50-60 days.

[0031] (7) Squeeze: Put it into a clo...

Embodiment 2

[0036] (1) Rice soaking: remove impurities from the japonica rice, weigh, wash, soak in water for 3-4 days, and soak the rice in water for 30cm.

[0037] (2) Steamed rice: Transfer to a steamer and cook for 10-20 minutes.

[0038] (3) Drenching the rice to cool down: pour cold water (10-30°C) over the rice until the rice cools to room temperature, drain the remaining water after pouring the rice, and transfer the rice to the brewing tank.

[0039] (4) Add distiller's grains: crush the rice wine grains and put them into the brewing tank from the discharge port, mix evenly to obtain a raw material mixture, and the mass ratio of grains to raw rice is 1:9.

[0040] (5) Adding koji: Add water, wheat koji, and distiller's mother into the brewing tank, and stir with the raw material mixture evenly. The mass ratio of raw material mixture to water, wheat koji and distiller's mother is 1000:950:160:85.

[0041] (6) Pre-fermentation: The fermentation temperature is controlled at 28-32°...

Embodiment 3

[0048] (1) Rice soaking: remove impurities from the japonica rice, weigh, wash, soak in water for 3-4 days, and soak the rice in water for 30cm.

[0049] (2) Steamed rice: Transfer to a steamer and cook for 10-20 minutes.

[0050] (3) Drenching the rice to cool down: pour cold water (10-30°C) over the rice until the rice cools to room temperature, drain the remaining water after pouring the rice, and transfer the rice to the brewing tank.

[0051] (4) Add distiller's grains: crush the rice wine grains and put them into the brewing tank from the discharge port, mix evenly to obtain a raw material mixture, and the mass ratio of the grains to the raw rice is 1:4.

[0052](5) Adding koji: Add water, wheat koji, and distiller's mother into the brewing tank, and stir with the raw material mixture evenly. The mass ratio of raw material mixture to water, wheat koji and distiller's mother is 1000:950:160:85.

[0053] (6) Pre-fermentation: The fermentation temperature is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com