Patents

Literature

37results about How to "High weight average molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

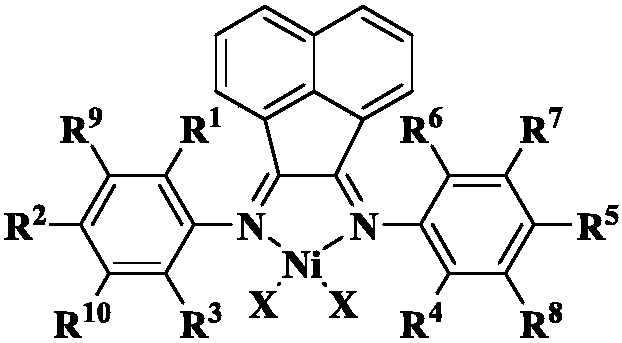

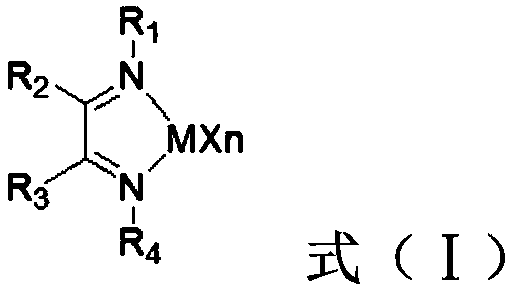

Catalytic system for olefin- olefin alcohol polymerization, olefin-olefin alcohol copolymerization method and polymer

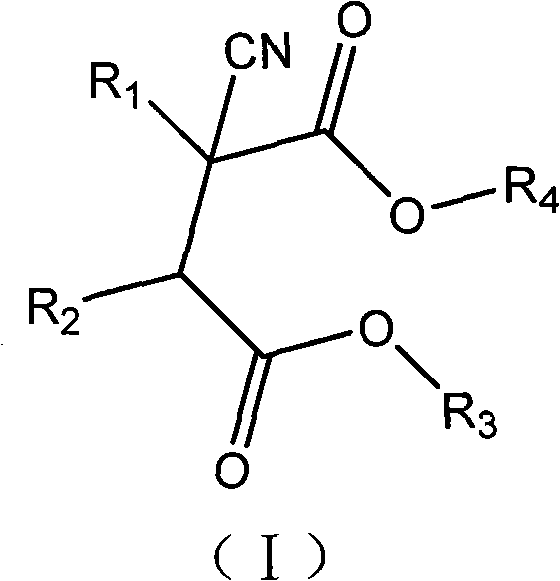

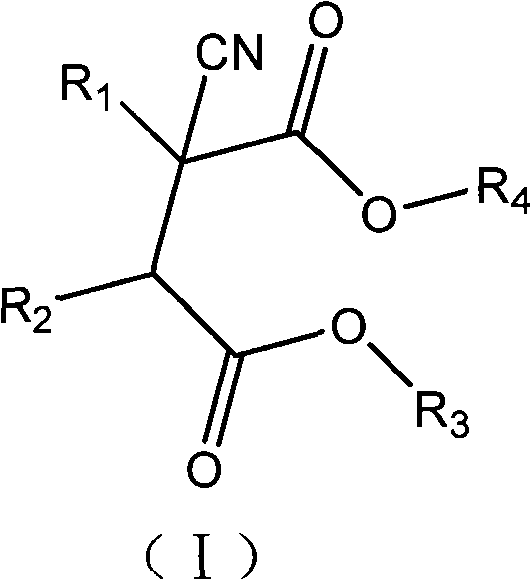

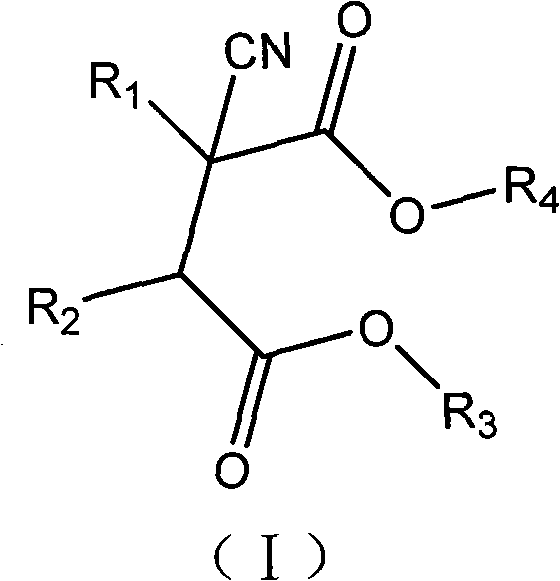

The invention relates to the field of polymers, the invention discloses a catalytic system for olefin- olefin alcohol copolymerization, an olefin-olefin alcohol copolymerization method and a polymer.The catalytic system comprises the following components: (1) a main catalyst which is selected from at least one of the group consisting of metal complexes as shown in formula (I), in the formula (I),R1 and R4 are each selected from a C1-C30 hydrocarbyl group or heterohydrocarbyl group; R2 and R3 are each selected from a hydrogen atom, a chlorine atom, a C1-C20 hydrocarbon group, and the like, and R2 and R3 may be optionally bonded to each other into a ring. M is a Group VIII metal; X is selected from the group consisting of halogen, hydrocarbyl and alkoxy; n is an integer satisfying the valence of the M; 2) a cocatalyst; 3) an olefin; 4) an alkene alcohol; 5) an alkane solvent; and a 6) chain transfer agent; the polymer has a high alcohol content and weight average molecular weight, a narrow molecular weight distribution, and does not contain a carboxylic acid or an alkali metal salt, and the catalyst has better thermal stability and a higher polymerization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

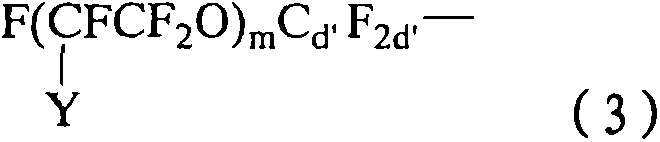

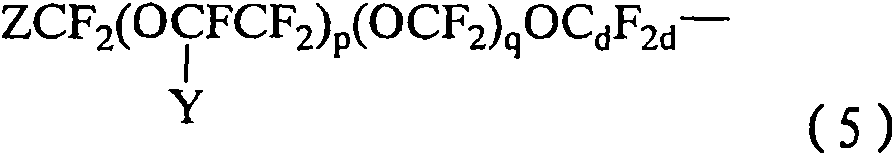

Fluorine-based surface treating agent for vapor deposition and article finished with the surface treating agent by vapor deposition

ActiveCN103146305AHigh weight average molecular weightImprove stain resistanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingSilanesGas phase

There is disclosed a fluorine-based surface treating agent for vapor deposition comprising (A) a hydrolyzable group-containing silane modified with a polymer containing a fluorooxyalkylene group and / or a partial hydrolytic condensate, and (B) a polymer containing a fluorooxyalkylene group having a higher weight average molecular weight than component (A), wherein components (A) and (B) are mixed in a weight ratio of from 6:4 to 9:1.

Owner:SHIN ETSU CHEM CO LTD

Preparation method of lightly-crosslinked aliphatic-aromatic copolyester

ActiveCN102336896AHigh weight average molecular weightHigh elongation at breakAlcoholReaction temperature

The invention provides a preparation method of lightly-crosslinked aliphatic-aromatic copolyester. The copolyester can be synthesized and prepared from the following components: a) aromatic dibasic acid, ester, anhydride or a mixture thereof; b) aliphatic dibasic acid, ester, anhydride or a mixture thereof; c) aliphatic dibasic alcohol or alicyclic dibasic alcohol; and d) a compound with three or more esterification functional groups. The preparation method comprises the following steps: adding the four components a, b, c and d into a reaction device according to a certain ratio; vacuumizing; filling nitrogen gas; reacting at 170-230 DEG C; vacuumizing to carry out polycondensation reaction after the completion of esterification and / or interesterification; taking out the product after the completion of reaction; and cooling and molding in water to obtain the copolyester. The invention overcomes the defect of high complexity in the copolyester preparation process in the prior art. Besides, by adding the component d, the invention further improves the performance of the copolyester and widens the application range of the copolyester.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

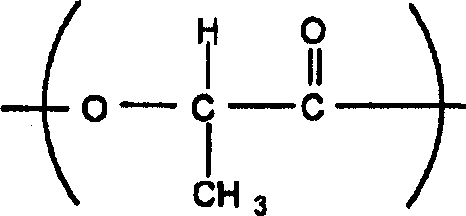

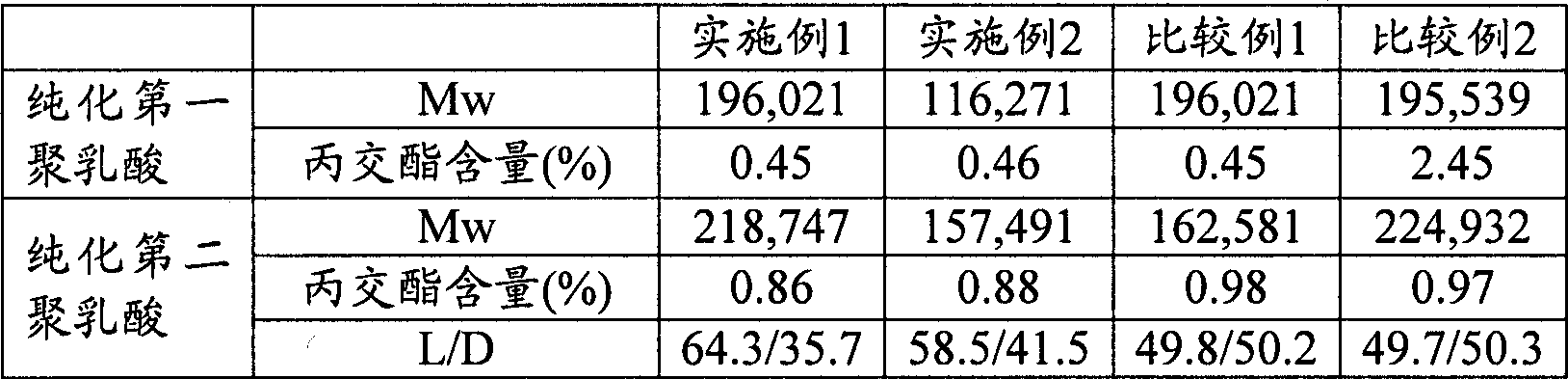

Polylactic acid and method for producing the same

A method of producing a stereocomplex polylactic acid having a high melting point and a high molecular weight, wherein only stereocomplex crystals are grown even when melting and crystallization are repeated. The method comprises the steps of: (1) obtaining a first polylactic acid by the ring-opening polymerization of a first lactide composed of lactic acid units of the same chirality; (2) obtaining a purified first polylactic acid by removing the lactide from the first polylactic acid in a molten state under reduced pressure; (3) obtaining a second polylactic acid by the ring-opening polymerization of a second lactide which differs from the first lactide in chirality in the presence of the purified first polylactic acid; and (4) obtaining a purified second polylactic acid by removing the lactide from the second polylactic acid in a molten state under reduced pressure.

Owner:TEIJIN LTD +1

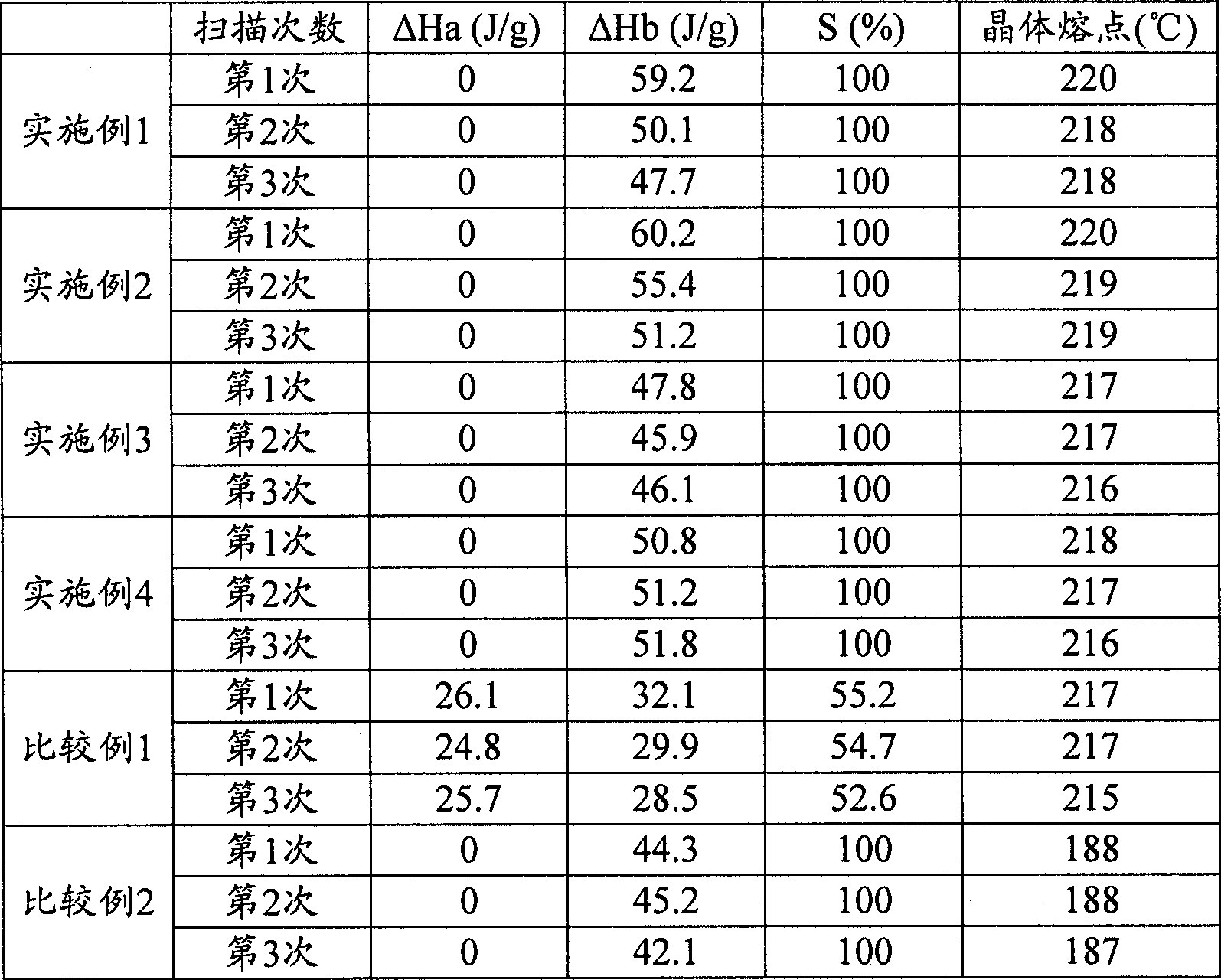

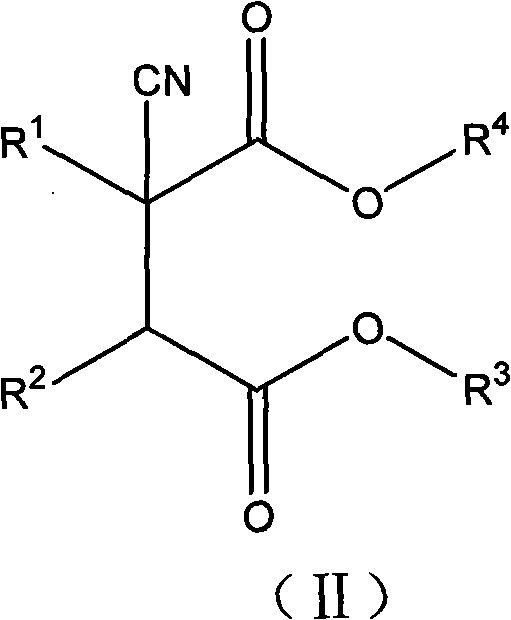

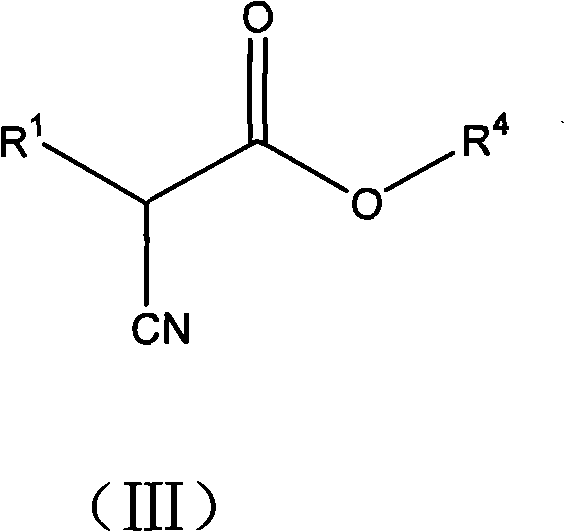

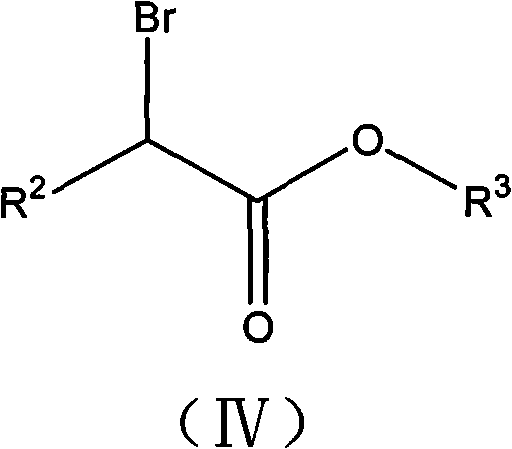

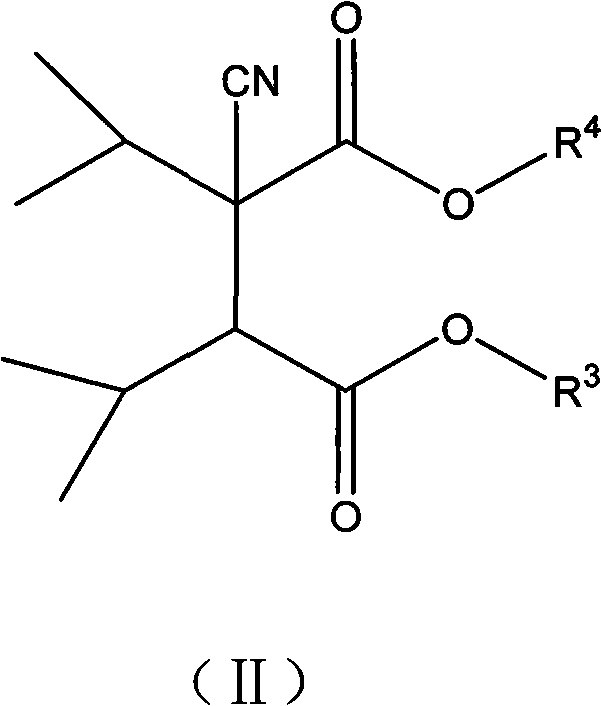

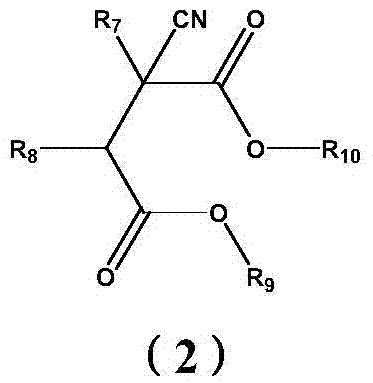

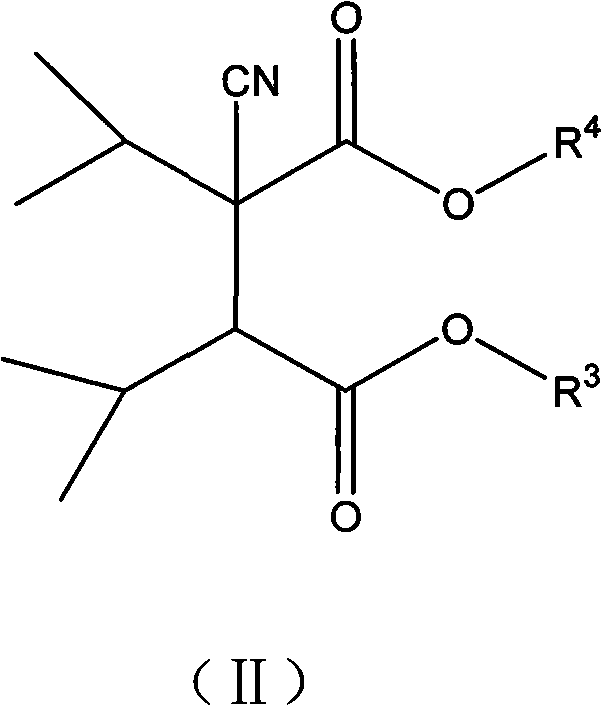

2-cycloalkyl-3-secondary alkyl-2-cyansuccinate compounds, preparation method thereof and application thereof

ActiveCN102372651AEase of industrial preparationEasy to industrializeCarboxylic acid nitrile preparationOrganic compound preparationElectron donorTitanium

The invention relates to 2-cycloalkyl-3-secondary alkyl-2-cyansuccinate compounds with a general formula represented by formula (II) and a preparation method thereof. A catalyst which is synthesized by treating the compounds as an internal electron donor of a titanium-contained solid catalyst component of an olefin polymerization catalyst has excellent performances and has a high activity on the propylene polymerization, the isotacticity degree of obtained polymers is good, and the molecular weight distribution of the obtained polymers is wide. Comprehensive performances of the catalyst in the invention are better than comprehensive performances of catalysts which treat 2,3-dialkylsuccinate compounds or omega-cyan C2-C5 monobasic ester compounds as the internal electron donor and have been reported by literatures.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyphenylene sulfide resin synthesis process

ActiveCN109535426AReduce the content of metal ionsImproved performance characteristicsSynthesis methodsSodium hydrosulfide

The invention discloses a polyphenylene sulfide resin synthesis process, which aims to obtain a resin synthesis method with good particle formation, high product yield, high solvent recovery rate, andreduced corrosion degree of a polymerization reaction device. The method adopts sodium sulfhydrate containing sodium crystallization, sodium hydroxide, and p-dichlorobenzene as raw materials, and takes N-methylpyrrolidone as a solvent, and a condensation polymerization reaction is carried out in a synthesis system, after the low temperature and high temperature polycondensation is completed, acetate, NMP and an aqueous solution are added by a high-pressure pump, then the materials are insulated at a high temperature, cooled, and filtered, and a filter cake is purified by a NMP solvent, repeatedly washed with deionized water and filtered, and the filter cake is dried to obtain the polyphenylene sulfide resin. The polyphenylene sulfide resin synthesized by the invention is widely used in the fields of aerospace, electronic machinery, petrochemical, food, light industry, thermal power generation, cement industry, steel manufacturing, environmental protection, textile industry and the like.

Owner:德阳科吉高新材料有限责任公司

Catalyst component and catalyst for olefin polymerization

The invention relates to a catalyst component and a catalyst for olefin polymerization and application of the catalyst to olefin homopolymerization and copolymerization. In the invention, an alpha-cyano ester succinate compound containing a specific structure is used as an internal electron donor, a magnesium chloride and silicon dioxide composite carrier is used, and the technical means are matched with each other for use, so that the polymerization activity of the catalyst is also kept while the grain form of the catalyst is improved. The catalyst is used for propylene polymerization; a polymerization product has a high isotactic index and high weight-average molecular weight; and polypropylene with wide molecular weight distribution is obtained. Compared with the conventional 2,3-dialkyl ester succinate compound, the alpha-cyano ester succinate compound has the advantages of high easiness in preparation and high contribution to industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified low-melting-point polyester hot melt adhesive, and preparation method thereof

InactiveCN104726049AReduce melt viscosityHigh weight average molecular weightAdhesivesPolymer sciencePhosphate

The invention belongs to the technical field of polyester adhesive, and specifically relates to a modified low-melting-point polyester hot melt adhesive, and a preparation method thereof. The modified low-melting-point polyester hot melt adhesive comprises, by weight, 88 to 94% of a polyester dihydric alcohol, 2 to 4% of polyether phosphate ester, and 5 to 9% of hyperbranched polyester; wherein the polyester dihydric alcohol is a condensation polymerization product of a dicarboxylic acid with a C2-6 dihydric alcohol, the dicarboxylic acid comprises terephthalic acid, m-phthalic acid, and unnecessary C6-12 aliphatic dicarboxylic acid units, and weight-average molecular weight ranges from 26000 to 37000. According to the preparation method, polyether phosphate ester is used for chemical modification of the polyester dihydric alcohol, and an appropriate amount of hyperbranched polyester is added, so that the obtained modified low-melting-point polyester hot melt adhesive possesses relatively low melt viscosity, relatively high weight-average molecular weight, and excellent physical properties and bonding strength.

Owner:HARBIN SONGJIANG FOOTWEAR CO LTD

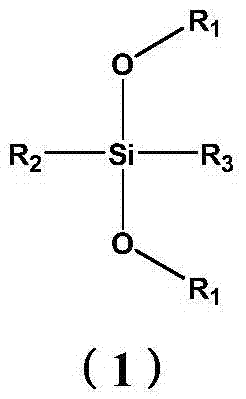

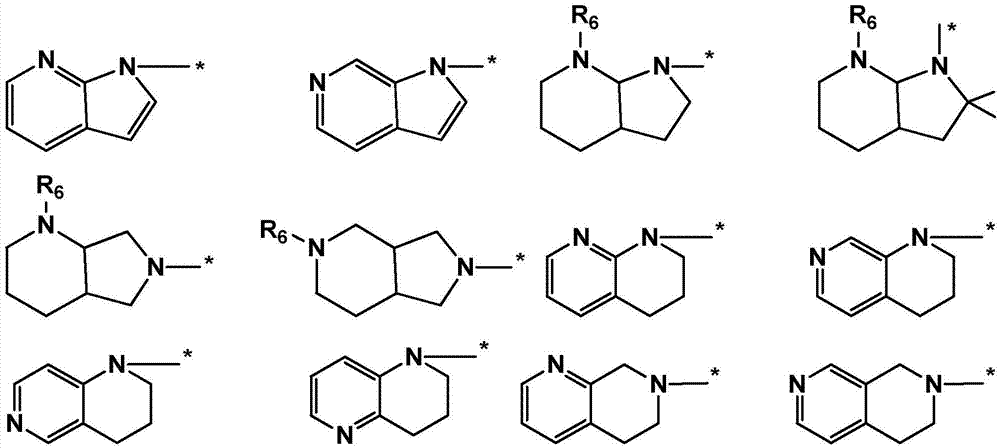

Catalytic system for preparation of wide-distribution polyolefin, and application of catalytic system

The invention relates to a catalytic system for preparation of wide-distribution polyolefin, and application of the catalytic system. The catalytic system comprises a solid catalyst component (A), a cocatalyst (B) and a first external electron donor (ED1), wherein the component (A) is a magnesium halide loaded Ti solid component and contains a composite internal electron donor (ID); the first external electron donor (ED1) is selected from one or more of compounds as shown in a general formula (1), (the formula is as shown in the description); and the R1 is selected from C1-C6 alkyl, C3-C8 naphthenic base, C6-C14 aryl or C6-C14 ceteroary, R2 is selected the formulas as shown in the description, and R3 is selected from OR1, R2, C1-C6 alkyl and C3-C8 naphthenic base. When being applied to olefin polymerization, the catalytic system has various advantages: catalytic activity and hydrogen sensitivity are high; and the polymerization product is high in isotactic index, wide in molecular weight distribution and high in weight-average molecular weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polyphenylene sulfide resin for melt blowing

PendingCN107722274AImprove Tangling EffectLower melt blown temperatureMonocomponent synthetic polymer artificial filamentBenzeneDecomposition

The invention discloses a preparation method of polyphenylene sulfide resin for melt blowing. The preparation method is characterized by comprising the following steps: reacting p-dihalogenated benzene, an S<-2>-containing compound, an amide organic compound with alkali salt at a temperature 180-250 DEG C and a pressure of 0.1MPa-5.0MPa for 1-24 hours, so as to obtain a linear PPS prepolymer; andreacting the linear PPS prepolymer with dihalogenated hydrocarbon at a temperature of 230-280 DEG C and a reaction pressure of 0.1MPa-5.0MPa for 1-24 hours, so as to obtain PPS resin for melt blowing,wherein dihalogenated hydrocarbon is m-dihalogenated aromatic hydrocarbon or p-dihalogenated hydrocarbon. When being added, m-dihalogenated aromatic hydrocarbon is taken as a structural regulator, and the high-entanglement helical-structure or spring-structure PPS resin for melt blowing is obtained; and when being added, p-dihalogenated hydrocarbon is taken as a chain extender, and high-linearityand relatively-low-viscosity PPS resin for melt blowing is obtained. The preparation method is relatively low in processing temperature, so that the decomposition and carbonization of PPS can be inhibited, and the oxidation and crosslinking of PPS can be prevented.

Owner:TIANJIN POLYTECHNIC UNIV

Polyphenylene sulfide resin production process

Owner:德阳科吉高新材料有限责任公司

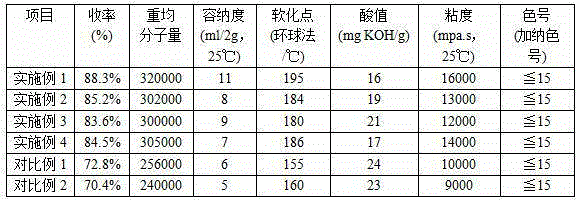

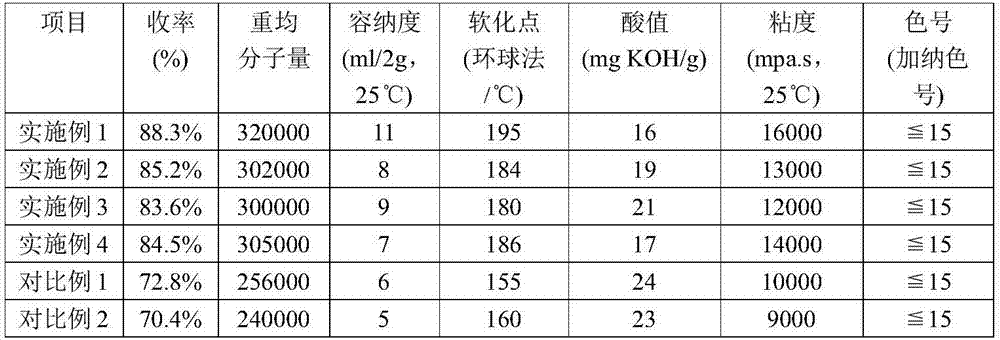

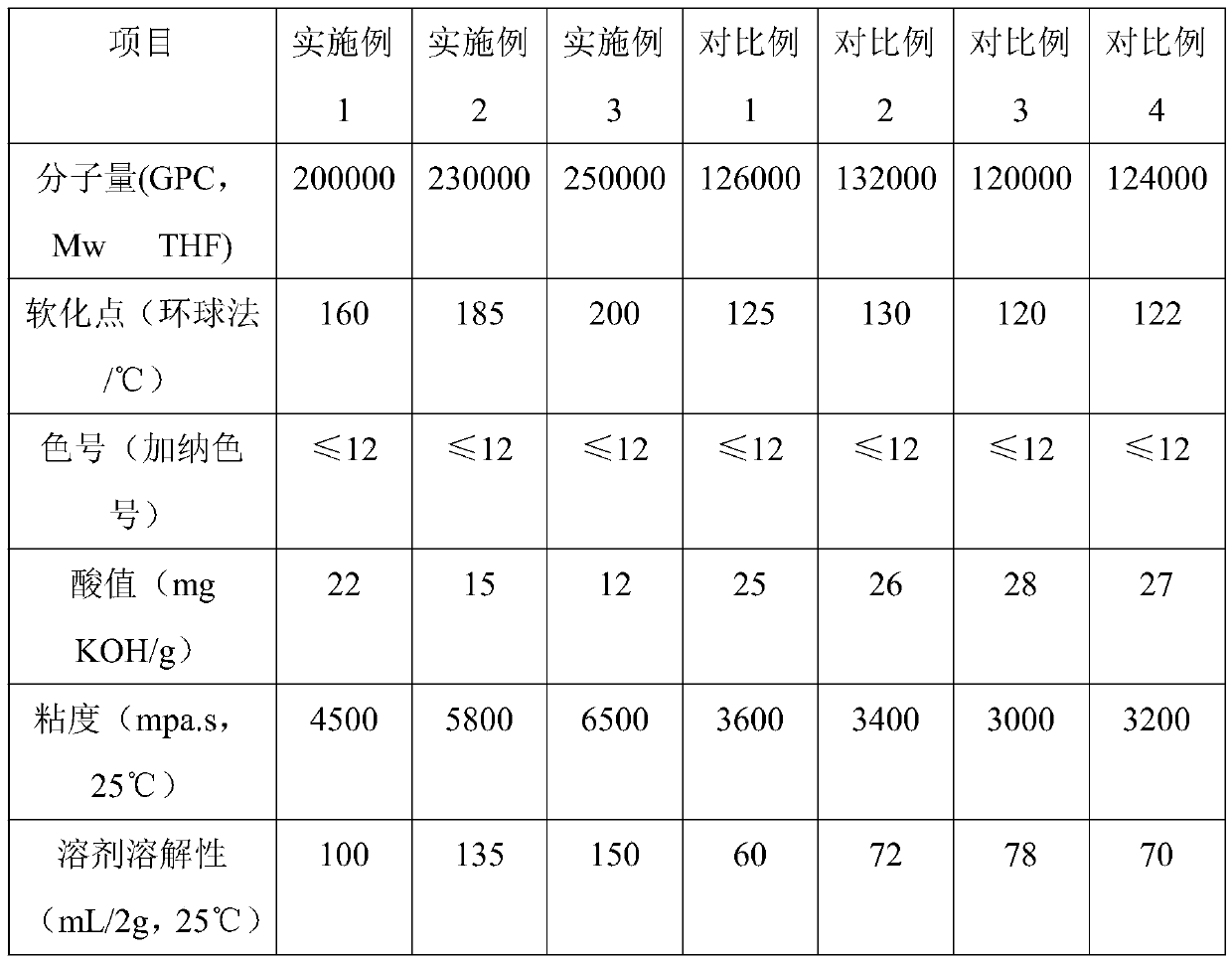

Structural resin for high-speed offset ink and preparation method thereof

ActiveCN105330800AHigh weight average molecular weightThe weight average molecular weight is as high as 300,000 or more, highInksNatural resin chemical modificationParaformaldehydePentaerithrityl

The invention discloses structural resin for high-speed offset ink and a preparation method thereof. The weight-average molecular weight of the structural resin for the high-speed offset ink is as high as 300 thousand or above, and the structural resin is high in softening point, low in acid value, high in viscosity, low in stickiness and suitable for the high-speed offset ink. The structural resin is prepared in the following steps that rosin is put in, fumaric acid is added at the temperature between 190 DEG C and 210 DEG C, and a reaction is performed at the same temperature; pentaerythritol is added at the temperature between 220 DEG C and 240 DEG C, and a reaction is performed at the temperature between 265 DEG C and 285 DEG C to obtain a rosin derivative; octylphenol, paraformaldehyde and triethylamine are subjected to a thermal reaction at the temperature between 90 DEG C and 95 DEG C to obtain phenolic resin, the temperature is kept between 240 DEG C and 255 DEG C, glycerinum and silicon dioxide are added, and a thermal reaction is performed at the temperature between 260 DEG C and 270 DEG C to obtain the structural resin. The method is simple, conditions are easy to control, and industrial production can be achieved.

Owner:FENGKAI HAILAN CHEM CO LTD

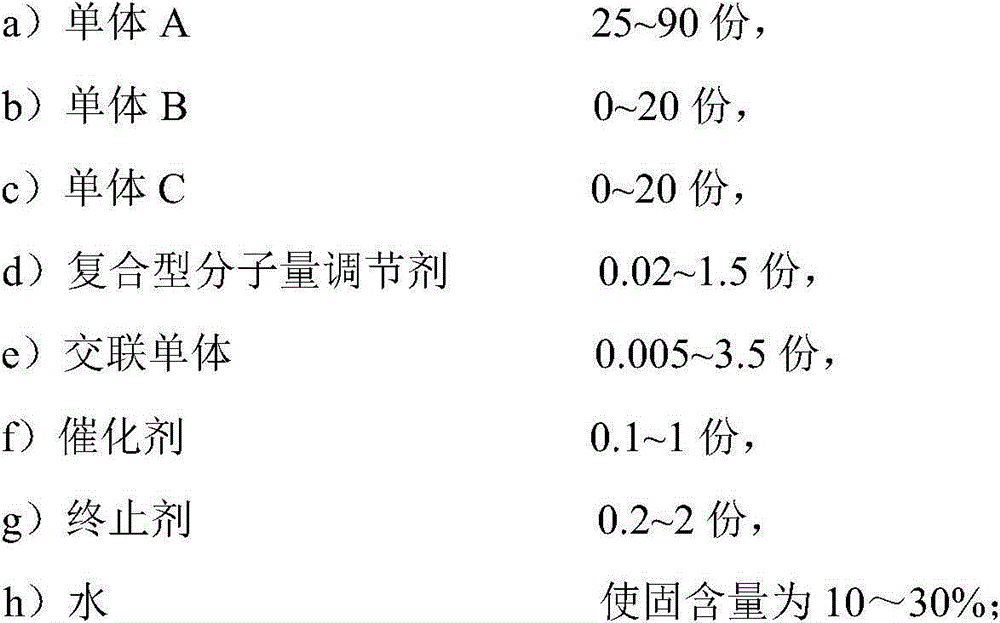

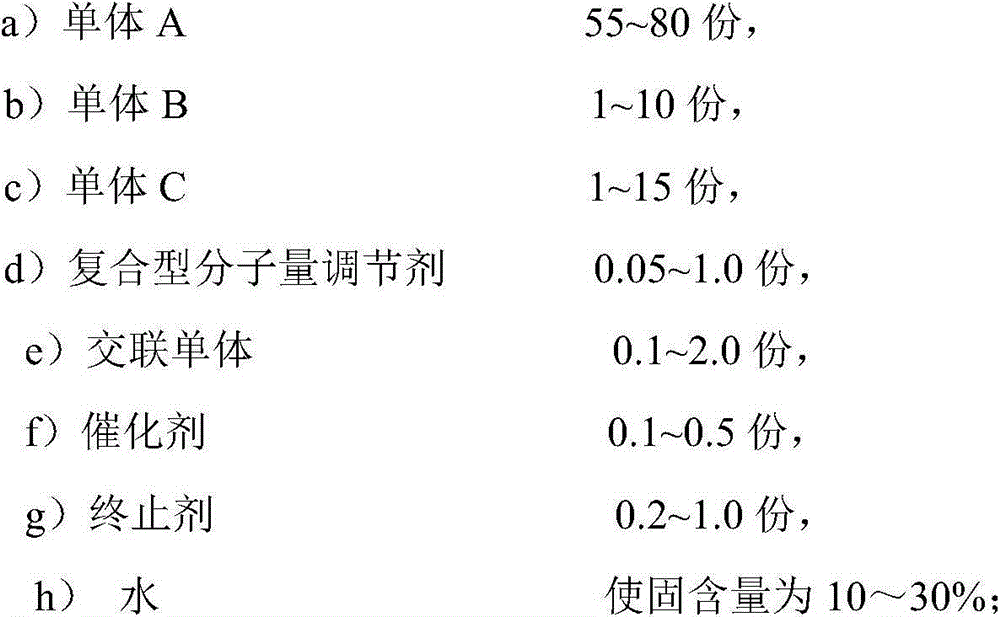

Preparation method and application of high molecular weight narrow distribution cross-linked polyacrylamide

ActiveCN103772603BHigh weight average molecular weightSmall molecular weight distributionReinforcing agents additionPaper/cardboardCross-linkSide effect

The invention relates to the field of papermaking and paper chemicals, aims to solve the problem that a paper used polyacrylamide dry strength additive, which has an efficient enhancement effect, and is good in adhesiveness, and environmentally friendly, is required to be prepared in the papermaking industry at present, and provides a preparation method of cross-linked polyacrylamide with high molecular weight and narrow distribution and application of the cross-linked polyacrylamide to papermaking. The cross-linked polyacrylamide prepared with the preparation method has higher weight-average molecular weight and narrower molecular distribution, and has the advantages of good enhancement effect, low loss of white water, good adhesiveness, less jello, environmental protection and the like. When the cross-linked polyacrylamide is applied to various fields, actual effective constituents are concentrated better, the operating barrier is reduced, and fewer side effects are caused.

Owner:HANGZHOU HANGHUA HARIMA PAPER CHEM

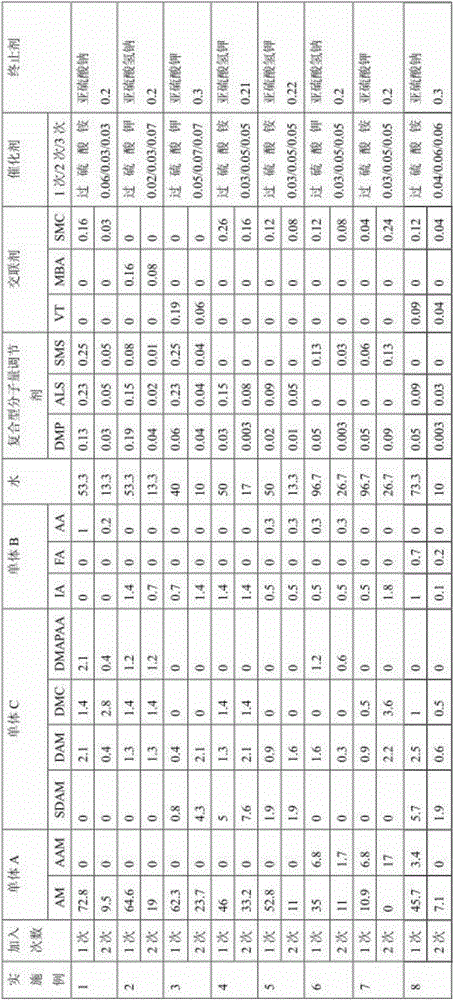

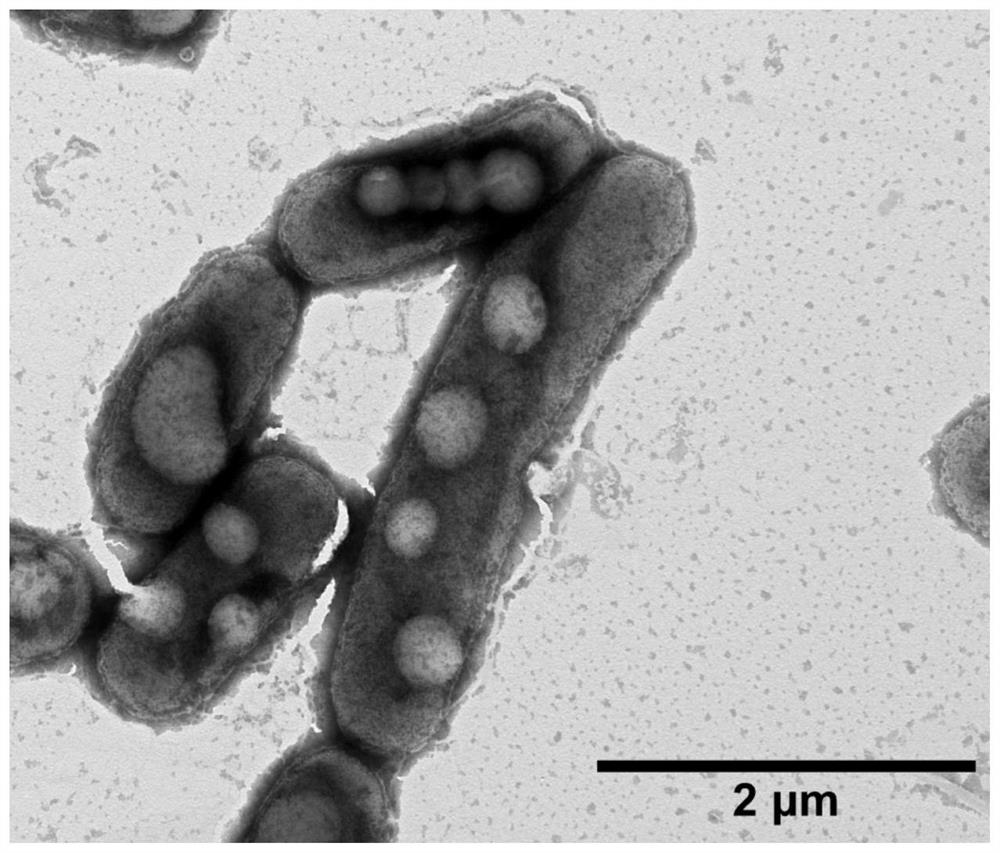

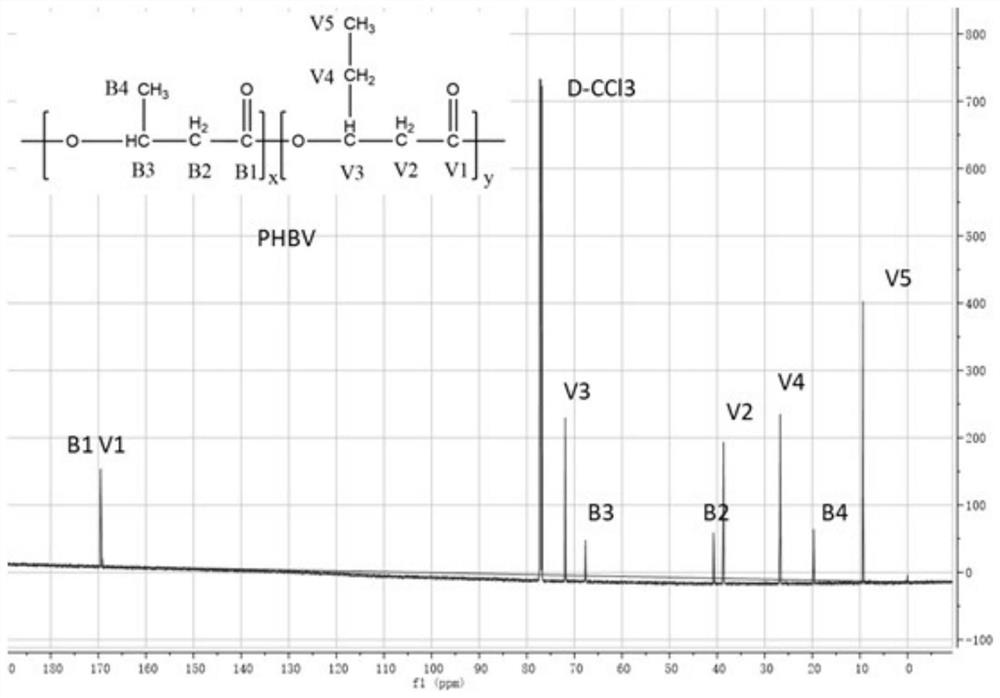

Rhodococcus pyridinivorans and application thereof in production of PHBV

ActiveCN112063567AHigh weight average molecular weightGood physical propertiesBacteriaMicroorganism based processesBiotechnologyHydroxybutyric acid

The invention discloses a strain of rhodococcus pyridinivorans and application thereof in production of PHBV. The strain rhodococcus pyridinivorans (Rhodococcus pyridinivorans)P23 is preserved in theChina centre for type culture collection (CCTCC) on August 7th, 2019; the address is Wuhan University, Wuhan, China; and the preservation number is CCTCC NO:M2019609. The strain rhodococcus pyridinivorans (Rhodococcus pyridinivorans)P23 disclosed by the invention can be used for efficiently synthesizing a copolymer PHBV of 3-hydroxybutyric acid and 3-hydroxyvaleric acid in a mineral salt culture medium by taking terephthalic acid or terephthalate as a substrate. The monomer content of 3-hydroxyvaleric acid in the PHBV synthesized by the strain rhodococcus pyridinivorans (Rhodococcus pyridinivorans)P23 in the invention is more than 60%; furthermore, the weight-average molecular weight of the PHBV is higher than 600 kDa; and the PHBV has excellent physical properties and thermodynamic properties, and has a good application prospect.

Owner:THIRD INST OF OCEANOGRAPHY MINIST OF NATURAL RESOURCES +1

Ring opening polymerization method of PBAT/PLA (poly(butylene adipate-co-terephthalate)/poly(lactic acid)) block copolymer

The invention provides a ring opening polymerization method of a PBAT / PLA (poly(butylene adipate-co-terephthalate) / poly(lactic acid)) block copolymer, which includes steps of feeding aliphatic diol in a reaction kettle with a prepolymer PBAT; preparing PBAT of which both ends have hydroxyls; feeding the PBAT of which both ends have hydroxyls and lactide into a reaction kettle; after materials in the kettle are completely melted, adding catalyst B for reaction to obtain PBAT-PLA block copolymer. The ring opening polymerization method of the PBAT / PLA has high output of block copolymer.

Owner:HENAN GREEN POLYMER CO LTD

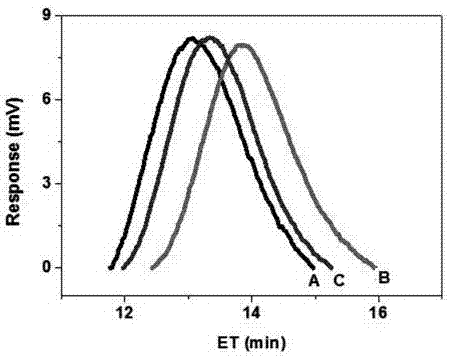

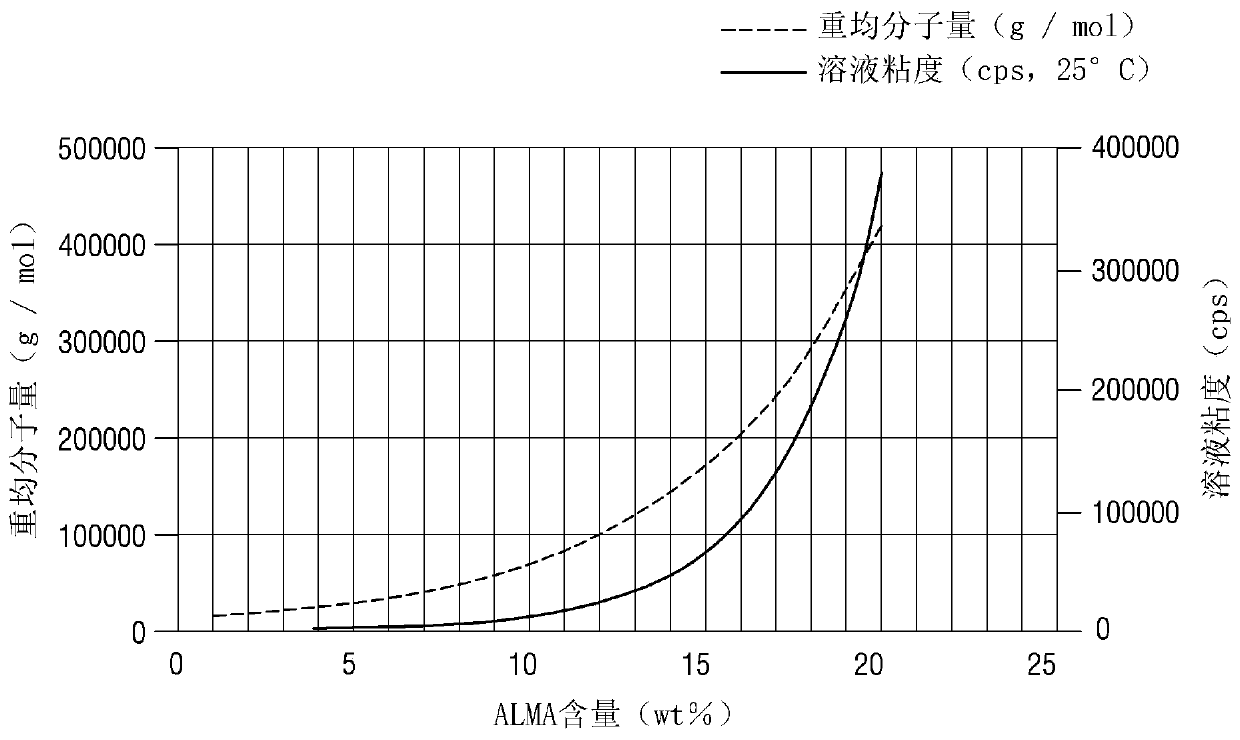

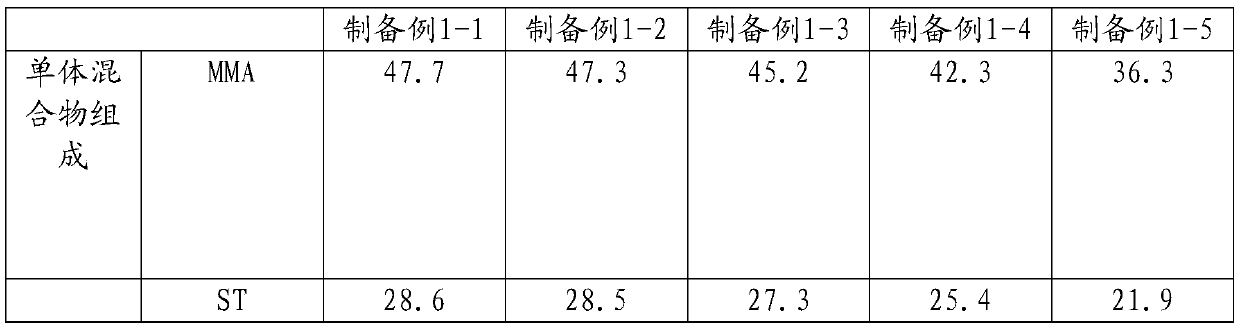

Alkaline water soluble resin, method for producing same, and emulsion polymer including alkaline water soluble resin

ActiveCN110198960AHigh weight average molecular weightPromote aggregationCoatingsAlkaline waterEmulsion

Provided are: an alkaline water soluble resin; a method for producing an alkaline water soluble resin; and an emulsion polymer including an alkaline water soluble resin. The alkaline water soluble resin is produced by polymerizing a first monomer which includes one or more among an acrylic monomer, a methacrylic monomer, or a styrene-based monomer and does not have an allyl group, and a second monomer which has an allyl group.

Owner:HANWHA CHEMICAL CORPORATION

Flexible composite bulletproof material

InactiveCN103673768AGood effectHigh weight average molecular weightPersonal protection gearFiberVulcanization

A flexible composite bulletproof material overcomes the defects that an existing bulletproof material is poor in impact force resistance, short in service life and poor in damp-proof performance. The flexible composite bulletproof material is manufactured according to the following processes that A, processed Kevlar fibers and fibers made of ultra-high molecular weight polyethylene are blended and woven into a composite Kevlar fiber layer; B, the woven composite Kevlar fiber layer is heated to 150-200 DEG C through infrared rays in a vacuum environment, and then vulcanization reaction is conducted at the temperature ranging from 200 DEG C to 450 DEG C; C, the reacted composite Kevlar fiber layer is woven, another composite Kevlar fiber layer is crocheted, the step two is repeated, and each composite Kevlar fiber layer and another composite Kevlar fiber layer are staggered by 0.25-0.5 wired tube; D, the step three is repeated many times, and then carbonization treatment is conducted on the lower surface of the multiple layers of woven composite Kevlar fiber layers. The flexible composite bulletproof material is strong in impact force resistance, good in bulletproof effect, long in service life, good in damp-proof performance, and suitable for being popularized and applied.

Owner:杨晓波

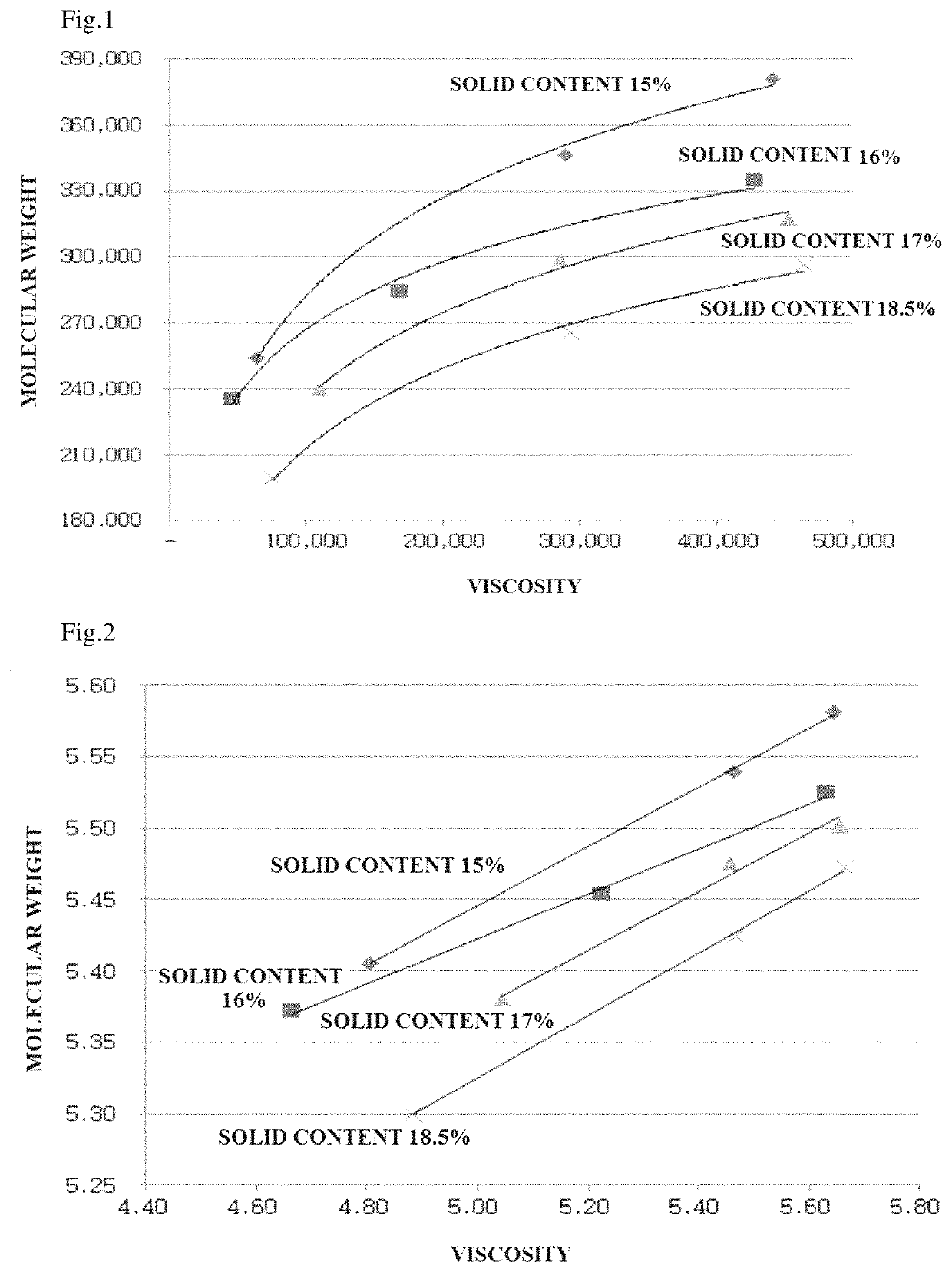

Polyimide film and method for producing same

ActiveUS10815338B2High weight-average molecular weightImprove thermal conductivityCarbon compoundsImidePolymer science

The present invention relates to a polyimide film and a preparation method thereof. According to the present invention, a polyamic acid solution having a high weight-average molecular weight may be obtained by adjusting viscosity and solid content of the polyamic acid solution, and thus, a desired polyimide film may be prepared therefrom. Furthermore, since a length of carbon chains rearranged during graphitization is increased, a graphite sheet having excellent thermal conductivity can be prepared from the polyimide film of the present invention. Also, since the polyimide film has improved windability by further including inorganic particles as a filler, it may facilitate the wind operation.

Owner:PI ADVANCED MATERIALS CO LTD

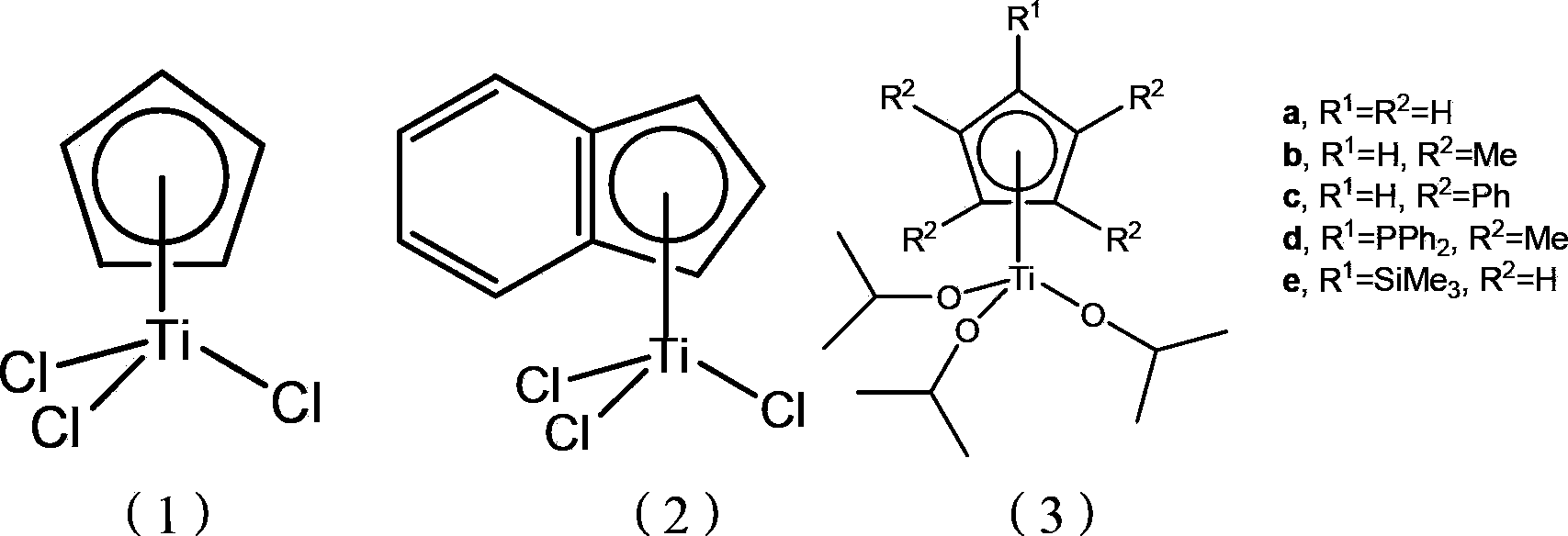

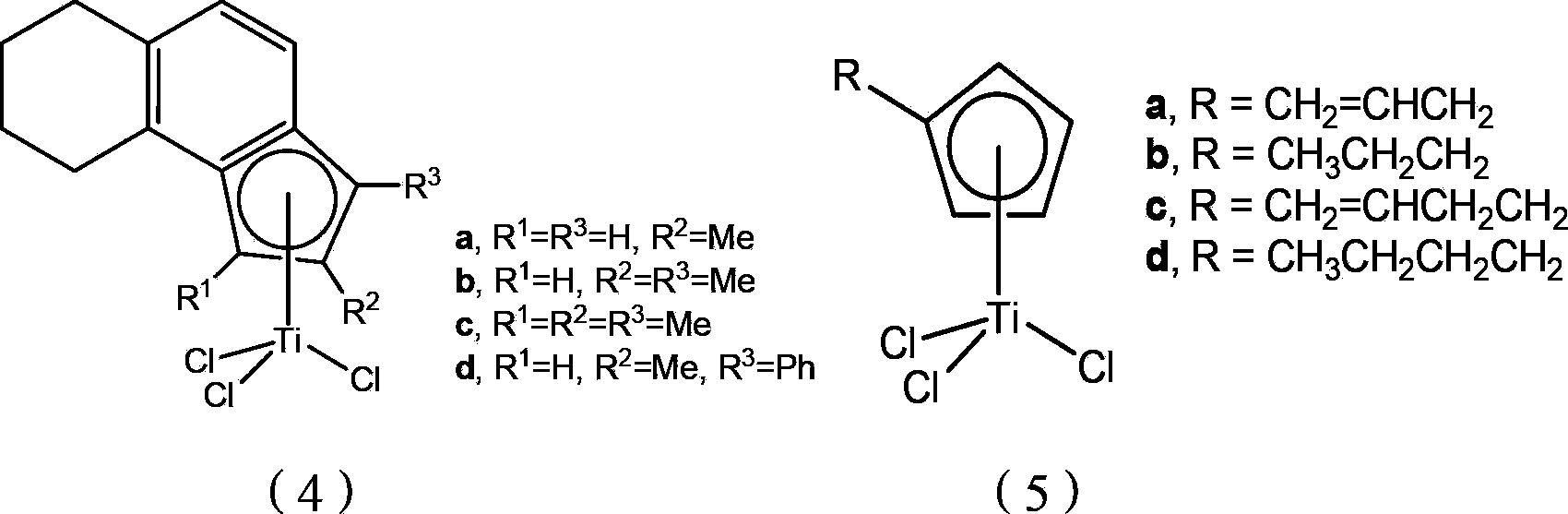

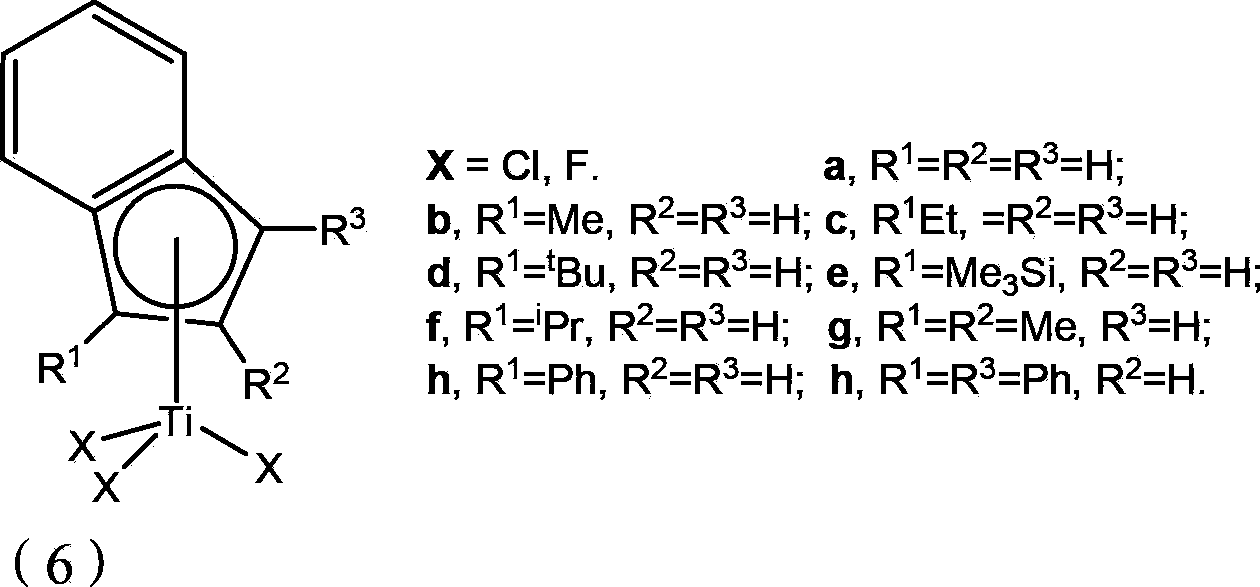

Single metallocene compound and application thereof

The invention discloses a single metallocene compound, whose structure is shown in the formula I, wherein, X is selected from halogen atom, alkyl, alkyloxy and aryloxy; Cp' is selected from cyclopentadienyl without substituent group or with substituent group alkyl, indenyl without substituent group or with substituent group alkyl, and fluorenyl without substituent group or with substituent group alkyl. The single metallocene compound provided by the invention can be used for preparing polyolefin, especially preparing syndiotactic polystyrene with appropriate catalytic activity, and SPS in the polymer has a high proportion, thereby the compound has a wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

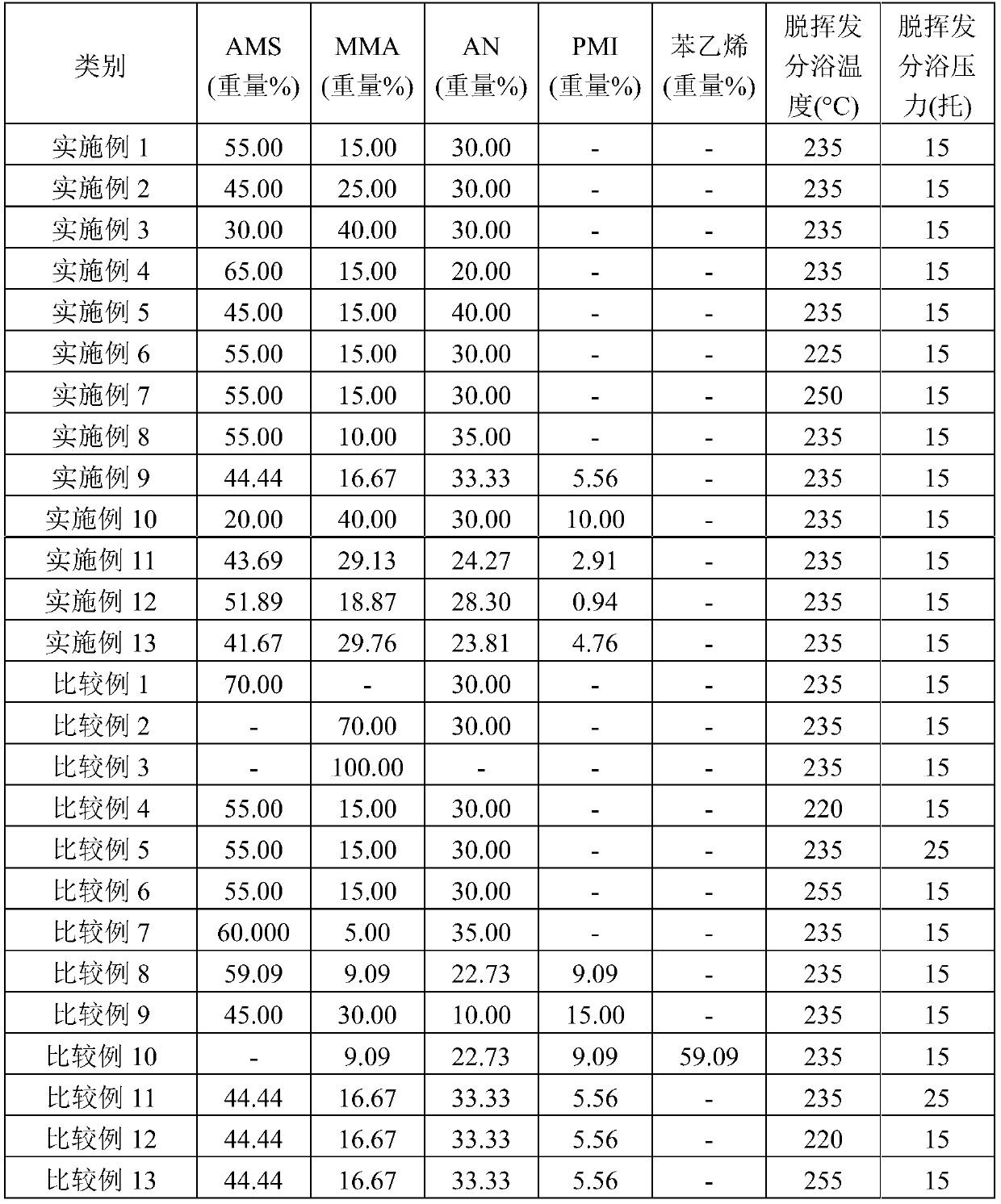

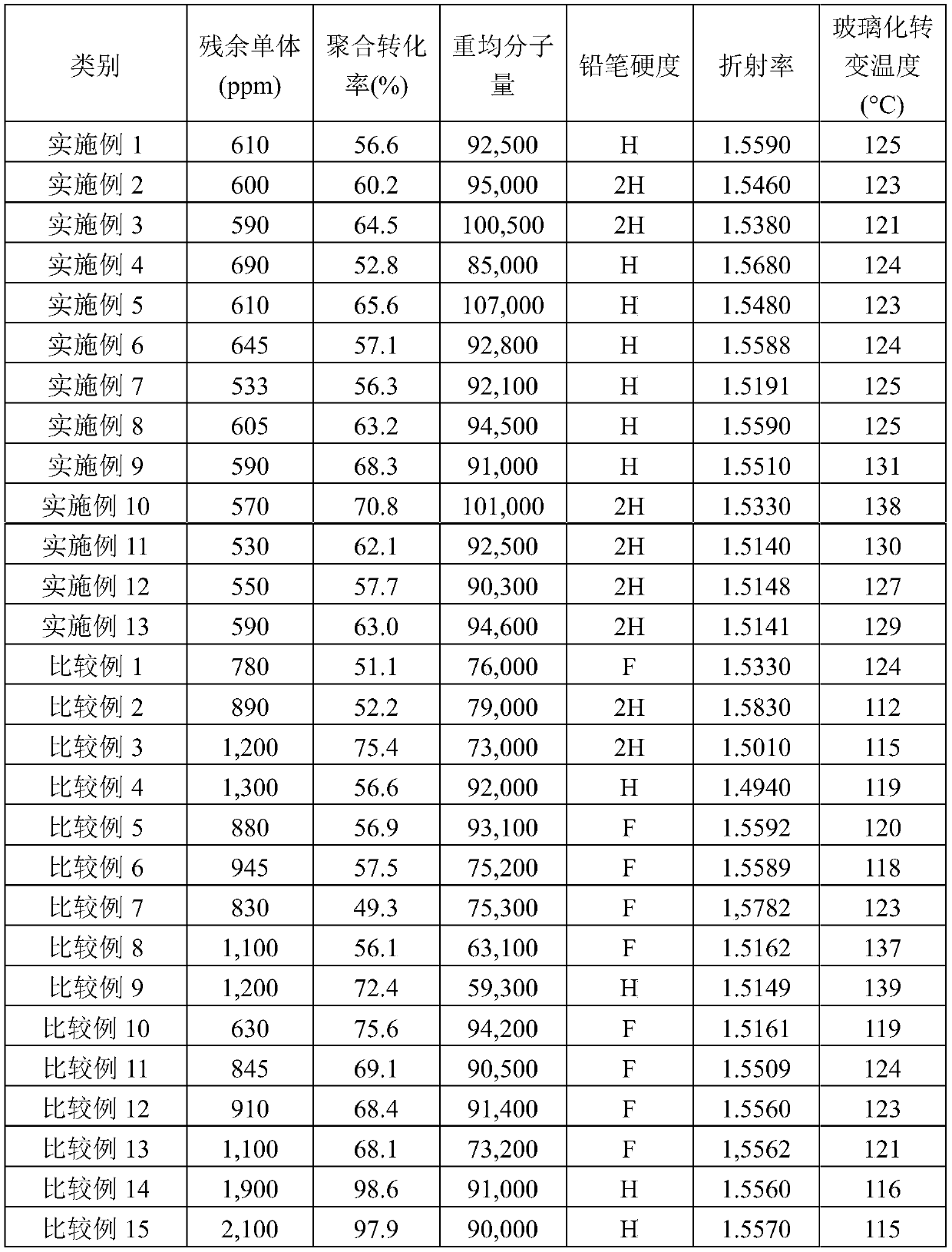

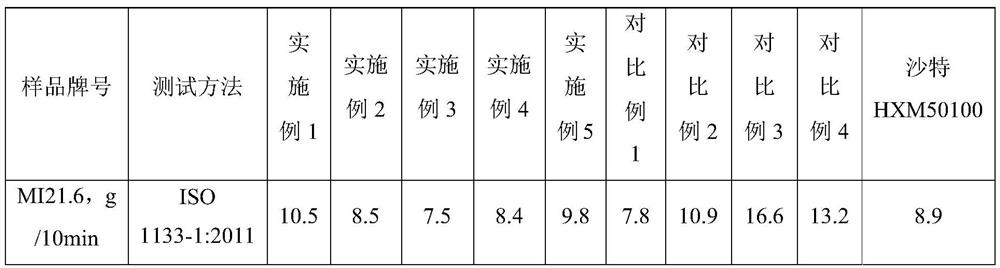

Copolymer and preparation method therefor

Owner:LG CHEM LTD

Preparation method of stacking-resistant rigid medium-sized hollow blow molding material

The invention discloses a preparation method of a stacking-resistant rigid medium-sized hollow blow molding material and an application of the prepared stacking-resistant rigid medium-sized hollow blow molding material. The preparation method comprises the steps that ethylene-hexene copolymerized polyethylene resin and auxiliaries are mixed and then subjected to extrusion granulation in a mixing mill, blow molding material particles are obtained, preferably, the content of a 1-hexene comonomer in the ethylene-hexene copolymerized polyethylene resin is 0.04 mol% to 0.10 mol%. The medium-sized hollow container blow molding material prepared by the preparation method disclosed by the invention is moderate in hexene content, wide in molecular weight distribution, high in density, high in crystallinity, strong in rigidity, high in melt strength, small in mold release expansion and stable in parison, and the processability and various physical and mechanical properties meet the requirements of medium-sized hollow container blow molding; a medium-sized hollow container blown by using the material disclosed by the invention has excellent stacking resistance.

Owner:CHINA PETROLEUM & CHEM CORP

Rosin modified phenolic resin for vacuum paint spraying high-grade coating and preparation method of rosin modified phenolic resin

The invention belongs to the technical field of forest product chemical product manufacturing, and specifically relates to a rosin modified phenolic resin for a vacuum paint spraying high-grade coating and a preparation method of the rosin modified phenolic resin. The preparation method of the rosin modified phenolic resin for the vacuum paint spraying high-grade coating, provided by the invention, comprises the following steps: firstly reacting tert-octylphenol with formaldehyde in different proportions under sodium hydroxide to prepare phenolic resin with different dissolubility, carrying out esterification on rosin through pentaerythritol to obtain rosin resin, carrying out a synthetic reaction on phenolic resin and the rosin resin in different proportions, then adding an antioxidant and an anti-ultravoilet assistant, and then carrying out refining to obtain the rosin modified phenolic resin. According to the method, the rosin modified phenolic resin for the vacuum paint spraying high-grade coating is prepared by adopting a numerical control method, the condition is easy to control, the rosin modified phenolic resin with different softening points and different dissolubility canbe produced, the prepared rosin modified phenolic resin is excellent in performance, high in softening point, low in color and luster, small in acid value and high in viscosity, and has extremely high dissolubility and molecular weight, and the product quality is easy to control.

Owner:FENGKAI HAILAN CHEM CO LTD

A kind of extraction process of polysaccharide in Hericium erinaceus spore powder

The present invention relates to the technical field of chemical extraction of active ingredients, in particular to an extraction process of polysaccharides in Hericium erinaceus spore powder, comprising the following steps: S1. The spore powder of Hericium erinaceus is broken to obtain the broken spore powder of Hericium erinaceus; S2. Broken Hericium erinaceus spore powder is mixed with mannitol solution according to the material-to-liquid ratio of 1g: (60-88) mL, and heat-treated for 45-70min to obtain a broken-wall Hericium erinaceus spore powder solution; S3. Broken Hericium erinaceus spore powder solution Introduce nitrogen gas into the spore powder solution, keep it for 12 minutes to half an hour under the pressure condition of 1-1.3MPa, and then quickly reduce the pressure to standard atmospheric pressure to obtain the crude polysaccharide extract; S4. Separating and concentrating the polysaccharide extract by alcohol precipitation and drying to obtain a polysaccharide extract. The process provided by the invention has high polysaccharide extraction yield, high weight-average molecular weight of the polysaccharide, low equipment requirements, and is suitable for large-scale industrial production.

Owner:福建胜美鲜生物科技有限公司

A kind of single metallocene compound and application thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component and catalyst for olefin polymerization

The invention relates to a catalyst component and a catalyst for olefin polymerization and application of the catalyst to olefin homopolymerization and copolymerization. In the invention, an alpha-cyano ester succinate compound containing a specific structure is used as an internal electron donor, a magnesium chloride and silicon dioxide composite carrier is used, and the technical means are matched with each other for use, so that the polymerization activity of the catalyst is also kept while the grain form of the catalyst is improved. The catalyst is used for propylene polymerization; a polymerization product has a high isotactic index and high weight-average molecular weight; and polypropylene with wide molecular weight distribution is obtained. Compared with the conventional 2,3-dialkyl ester succinate compound, the alpha-cyano ester succinate compound has the advantages of high easiness in preparation and high contribution to industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of structural resin for high-speed offset printing ink and its preparation method

ActiveCN105330800BHigh weight average molecular weightHigh softening pointInksNatural resin chemical modificationEngineeringParaformaldehyde

The invention discloses a structural resin for high-speed offset printing ink and a preparation method thereof. The structural resin for high-speed offset printing ink has a weight-average molecular weight of more than 300,000, a high softening point, a small acid value, and a high viscosity , Low viscosity, suitable for high-speed offset printing ink. The preparation of the structural resin is as follows: input rosin, add fumaric acid at 190-210°C, react at 190-210°C, add pentaerythritol at 220-240°C, and react at 265-285°C to obtain rosin derivatives; octylphenol , Paraformaldehyde and triethylamine are kept warm at 90-95°C to obtain phenolic resin; mix rosin and rosin derivatives and heat up to 240-255°C, add phenolic resin to react to obtain rosin phenolic condensate, keep the temperature at 240-255°C, Add glycerin and silicon dioxide, and keep warm at 260-270°C to react to obtain the structural resin. The method is simple, the conditions are easy to control, and it can be produced industrially.

Owner:FENGKAI HAILAN CHEM CO LTD

Rare earth catalyst and controllable polymerization method for conjugated diene in arene medium

The invention relates to a rare earth catalyst and a controllable polymerization method for conjugated diene in an arene medium. A rare earth metal carboxylate-based composite catalyst is adopted for catalyzing conjugated diene polymerization in the arene medium under the protection of inert gas to prepare high molecular weight high cis polyconjugated diene rubber. The rare earth catalyst has high catalytic activity and high directional selectivity for polymerizing the conjugated diene in the arene medium, ensures that the monomer conversion rate of the conjugated diene is over 70 percent and even over 90 percent, the cis-content of constitutional units of the polyconjugated diene is over 97 percent and is over 99 percent particularly, the obtained polyconjugated diene has the weight-average molecular weight (Mw) of 2.0*10<5>-1.5*10<6>, and the content of vinylarene participating in copolymerization is less than 1 percent (mol) and even cannot be tested.

Owner:BEIJING UNIV OF CHEM TECH

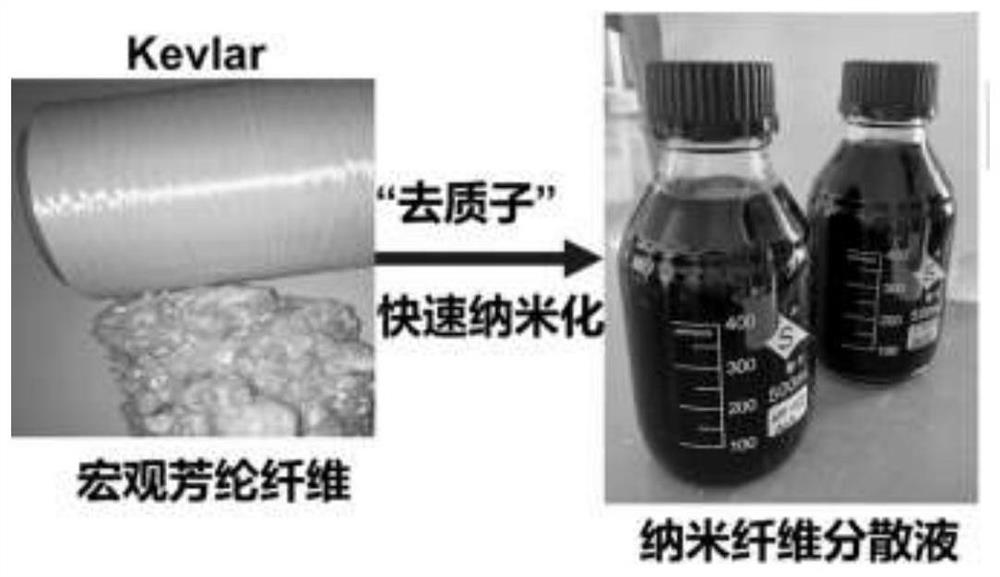

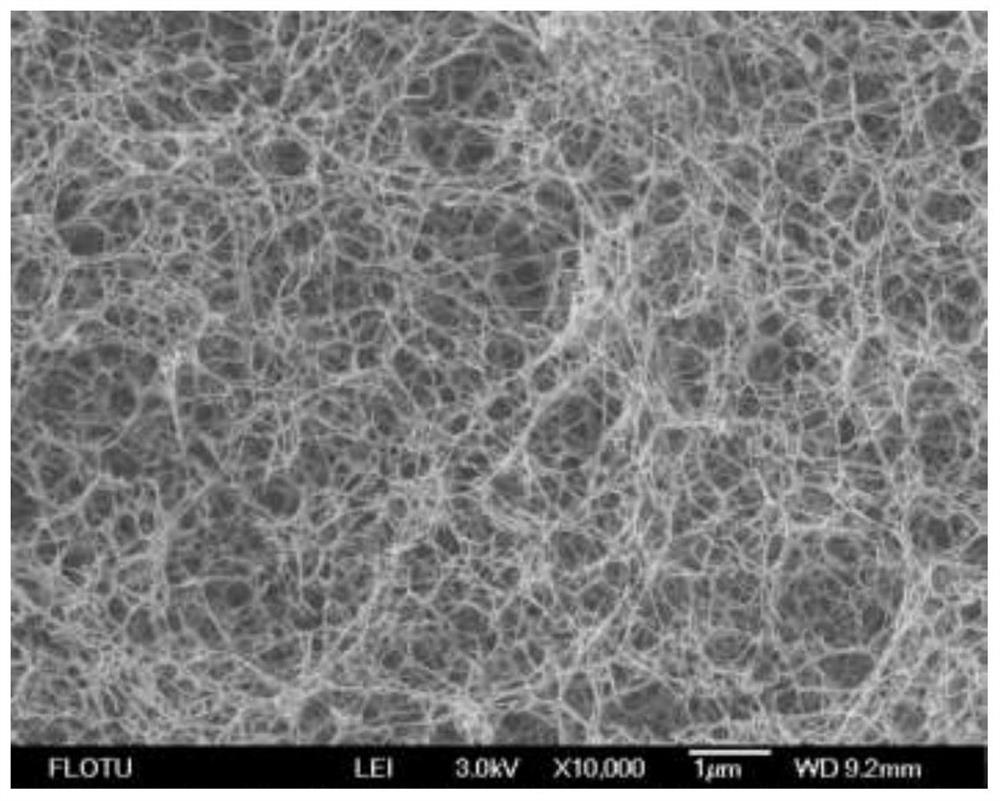

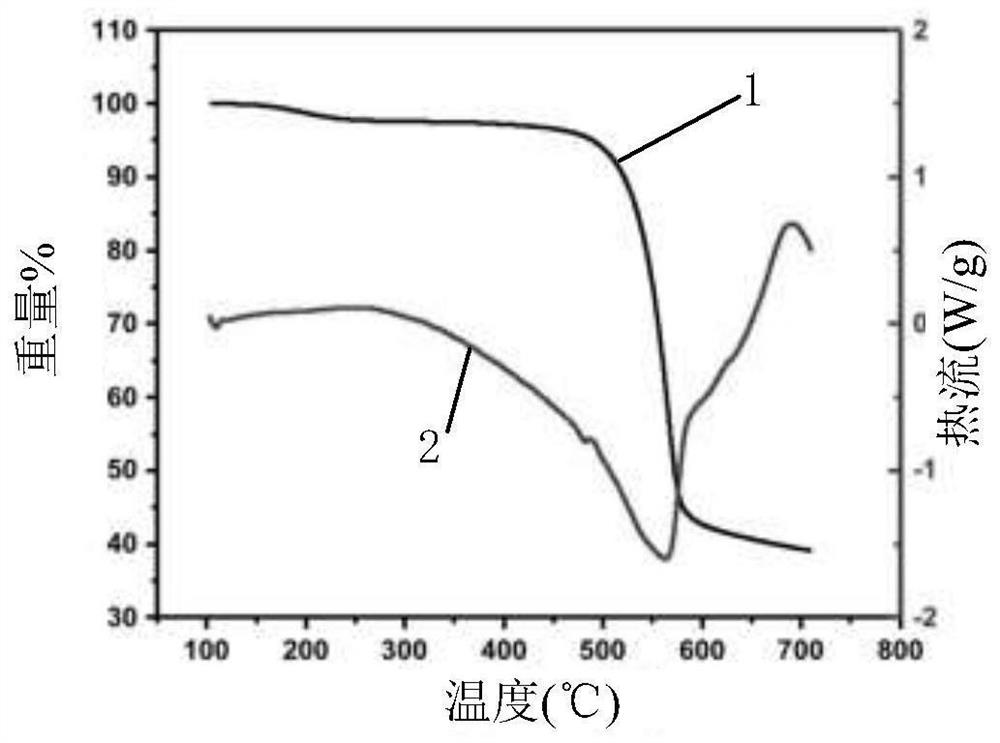

A method for preparing aramid nanofibers based on deprotonation of kevlar and nanofibers prepared therefrom

ActiveCN112878036BIncrease concentrationAccelerated destructionFibre typesBulk chemical productionPolymer scienceOrganic solvent

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of rosin-modified phenolic resin for vacuum spraying high-grade paint and preparation method thereof

ActiveCN108102546BHigh weight average molecular weightImprove solubilityRosin coatingsPolymer sciencePentaerythritol

The invention belongs to the technical field of forest product chemical product manufacturing, and specifically relates to a rosin modified phenolic resin for a vacuum paint spraying high-grade coating and a preparation method of the rosin modified phenolic resin. The preparation method of the rosin modified phenolic resin for the vacuum paint spraying high-grade coating, provided by the invention, comprises the following steps: firstly reacting tert-octylphenol with formaldehyde in different proportions under sodium hydroxide to prepare phenolic resin with different dissolubility, carrying out esterification on rosin through pentaerythritol to obtain rosin resin, carrying out a synthetic reaction on phenolic resin and the rosin resin in different proportions, then adding an antioxidant and an anti-ultravoilet assistant, and then carrying out refining to obtain the rosin modified phenolic resin. According to the method, the rosin modified phenolic resin for the vacuum paint spraying high-grade coating is prepared by adopting a numerical control method, the condition is easy to control, the rosin modified phenolic resin with different softening points and different dissolubility canbe produced, the prepared rosin modified phenolic resin is excellent in performance, high in softening point, low in color and luster, small in acid value and high in viscosity, and has extremely high dissolubility and molecular weight, and the product quality is easy to control.

Owner:FENGKAI HAILAN CHEM CO LTD

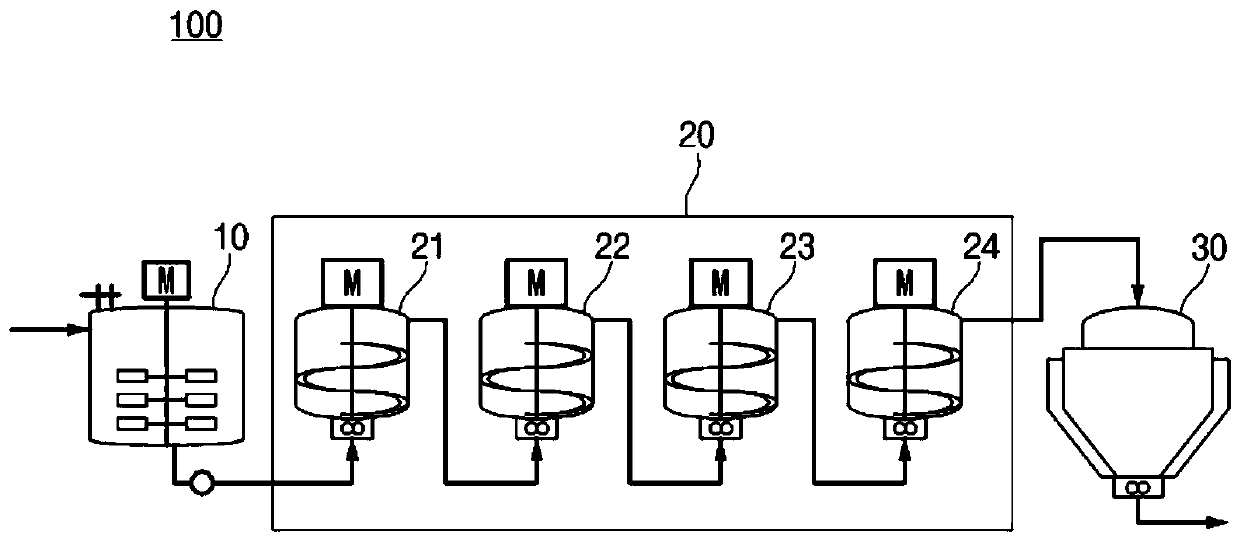

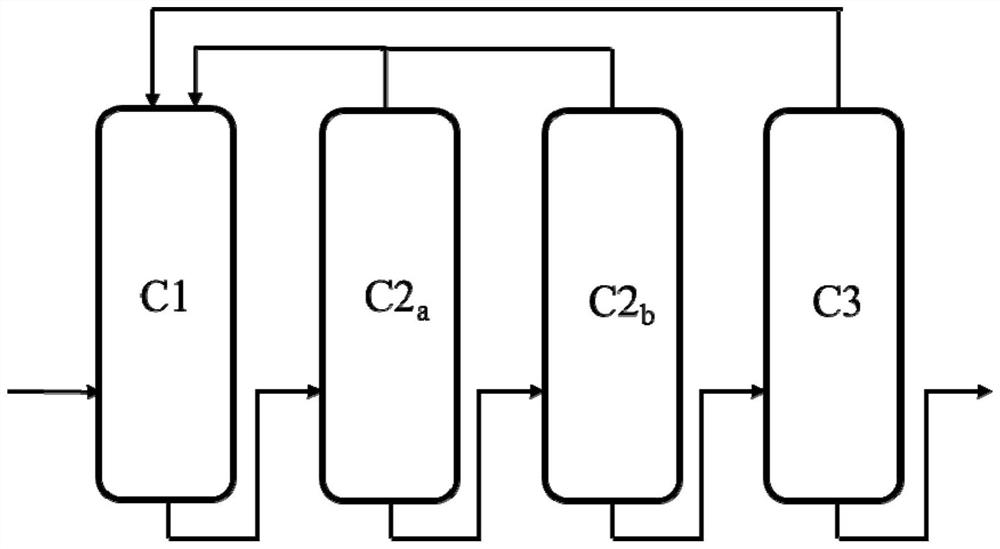

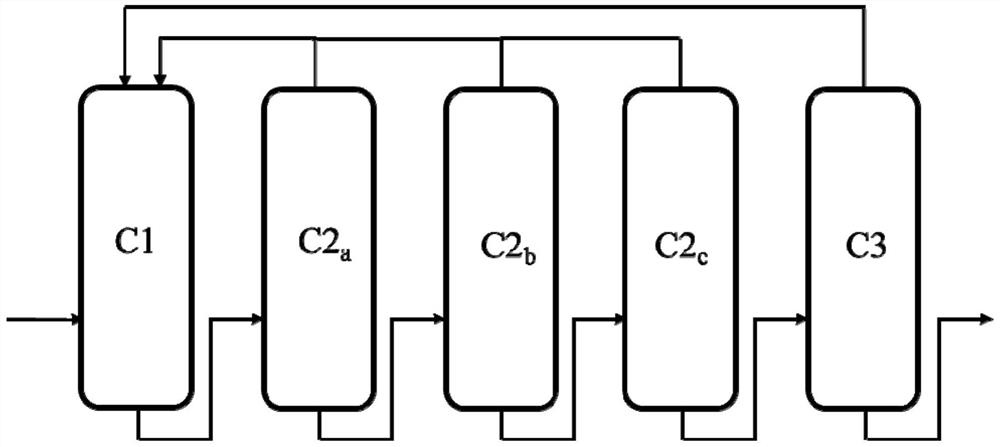

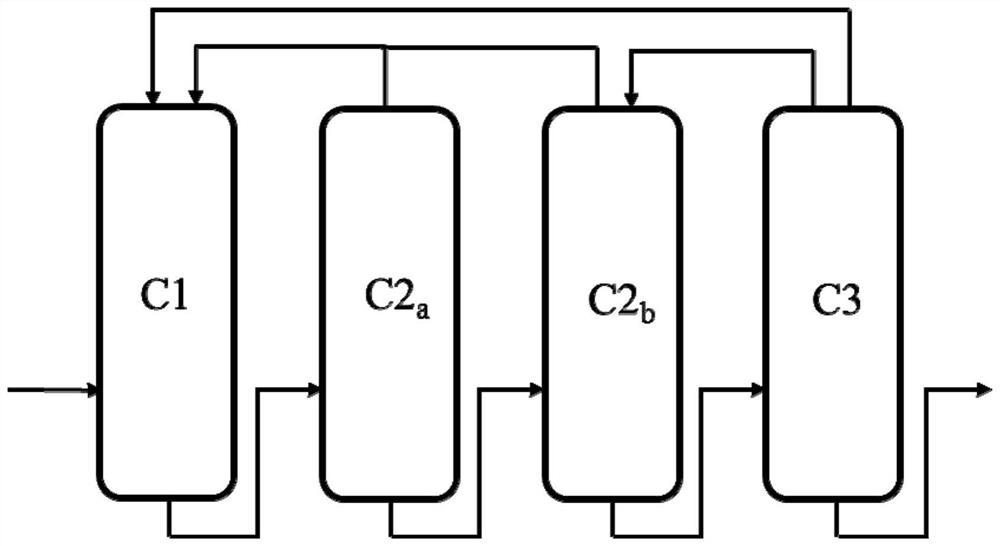

Preparation method and system of polyhydroxycarboxylate or polyhydroxycarboxylic acid polymer

The invention relates to a preparation method and system of a polyhydroxycarboxylate or a polyhydroxycarboxylic acid polymer. The method comprises the following steps: under the action of a catalyst,carrying out a pre-polymerization reaction on a raw material hydroxyl carboxylate monomer and / or hydroxyl carboxylic acid monomer for 0.5-48 h under the conditions that the absolute pressure is 100-600 kPa and the temperature is 100-250 DEG C, and separating reaction byproducts to obtain a pre-polymerization product; reducing the pressure of the pre-polymerization product, carrying out a polymerization reaction for 1-72 h under the conditions that the absolute pressure is 5-20 kPa and the temperature is 130-280 DEG C, and separating reaction byproducts, unreacted monomers and monomer oligomersto obtain an intermediate polymerization product; and reducing the pressure of the intermediate polymerization product, carrying out a final polymerization reaction for 0.5-20 h under the conditionsthat the absolute pressure is 0.1-1 kPa and the temperature is 160-280 DEG C, and separating to obtain the product polyhydroxycarboxylate or polyhydroxycarboxylic acid polymer. The polymer has the advantages of high molecular weight, high preparation method and system efficiency and low energy consumption.

Owner:PUJING CHEM IND SHA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com