Copolymer and preparation method therefor

一种共聚物、混合物的技术,应用在共聚物及其制备领域,能够解决共聚物分子量降低、共聚物颜色改变、缺陷比例增加等问题,达到优异加工性能、优异耐擦伤性、重均分子量高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

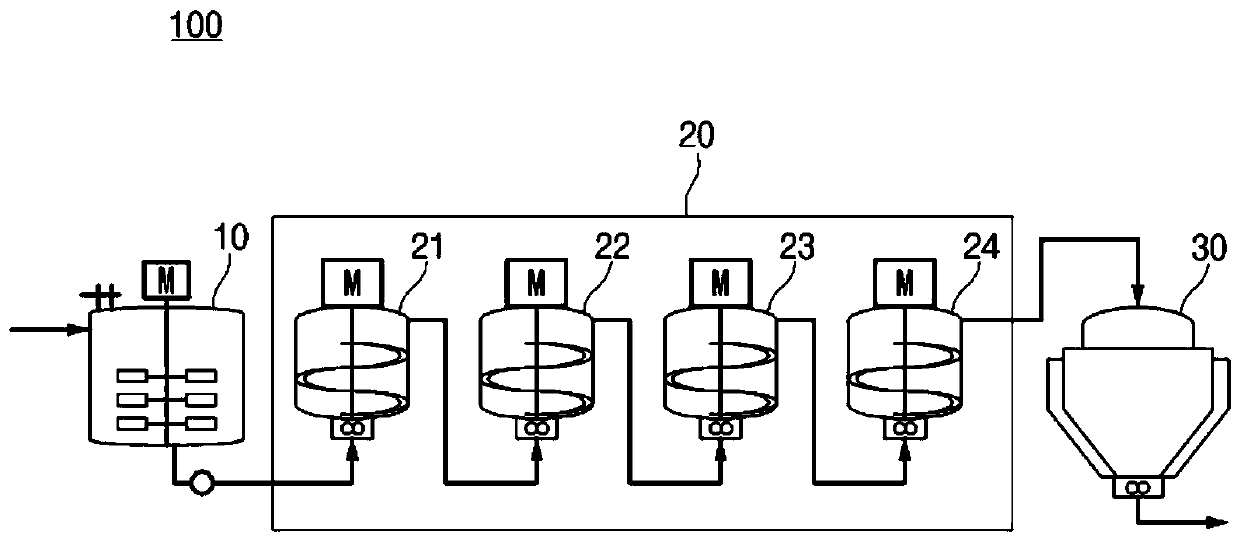

[0069] The preparation method of the copolymer according to one embodiment of the present invention comprises: carrying out the continuous mass polymerization of monomer mixture in more than four reactors; The polymer obtained by the reaction is volatilized to separate the polymer, wherein, based on the total weight of the monomer mixture, the monomer mixture comprises 20% by weight to 65% by weight of an alkyl styrene monomer, 10% by weight to 40% by weight of (meth)acrylate monomers and 20% to 40% by weight of aromatic vinyl monomers, wherein the temperature of the devolatilization bath is 223°C to 252°C, and the pressure is 20 Hold the following.

[0070] Here, the monomer mixture may further include 0.5% to 10% by weight of a maleimide-based monomer based on the total weight of the monomer mixture.

[0071] The description about the constituent elements and the composition of the monomer mixture is the same as the description referring to the above-mentioned copolymer.

...

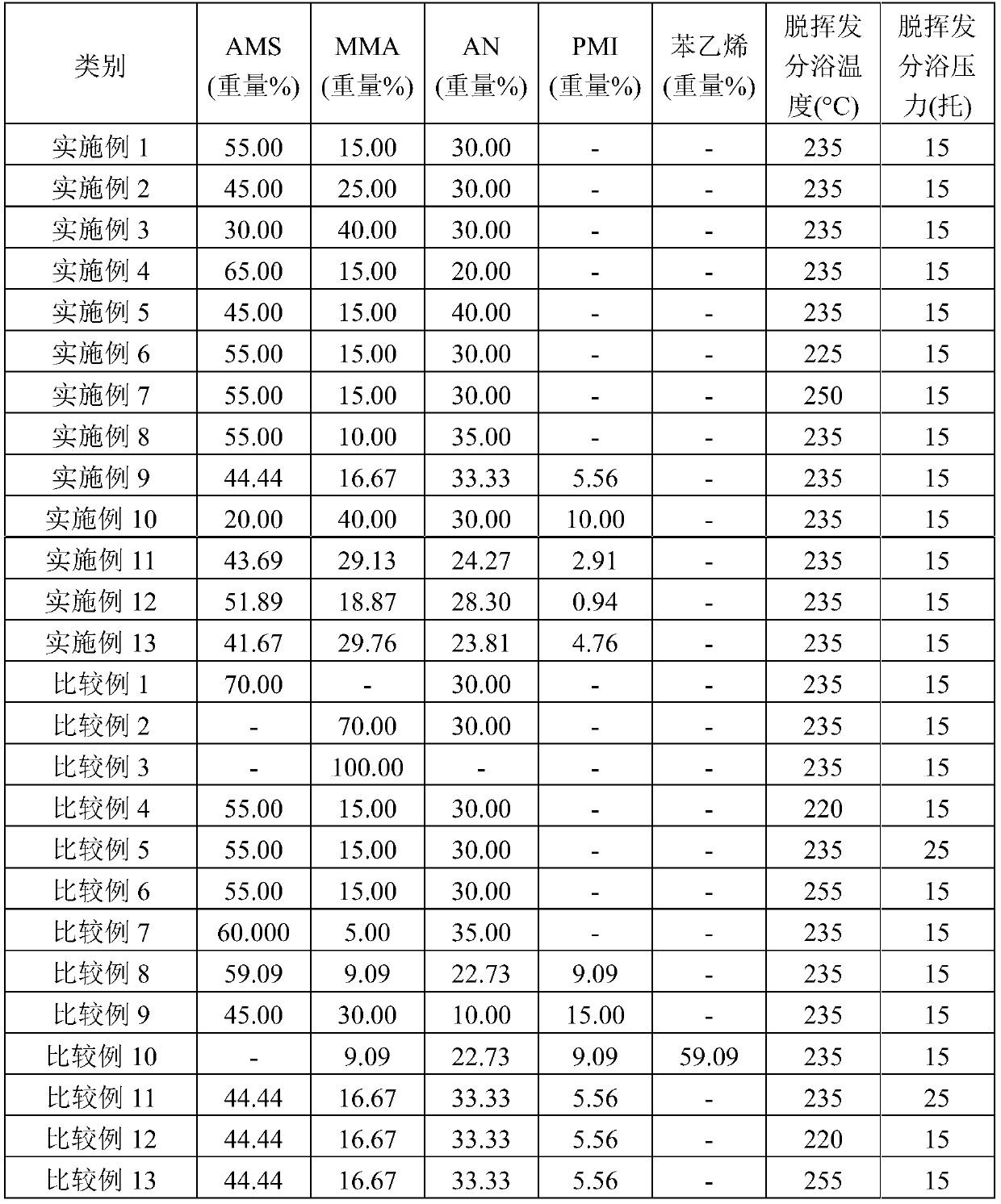

Embodiment 1 to Embodiment 13 and comparative example 1 to comparative example 13

[0093] Add 95 parts by weight of a monomer mixture containing the monomers described in Table 1 below, 5 parts by weight of toluene as a reaction solvent, and 0.1 parts by weight of 1,1-bis(tert-butoxy)cyclo as an initiator Hexane was used to prepare the polymerization solution. The polymerization solution was fed into the first polymerization reactor of 26 L at a rate of 7 kg / hour for the first bulk polymerization at 110° C., and then fed into the second polymerization reactor of 16 L for the second bulk polymerization at 110° C. Polymerization, then fed into the third polymerization reactor of 16L to carry out the third bulk polymerization at 110°C, and then fed into the fourth polymerization reactor of 16L to carry out the fourth bulk polymerization at 110°C, thus completing the continuous bulk polymerization. After that, unreacted monomer and reaction solvent were recovered and removed from the devolatilization bath at the temperature and pressure described in Table 1 to ...

experiment example 1

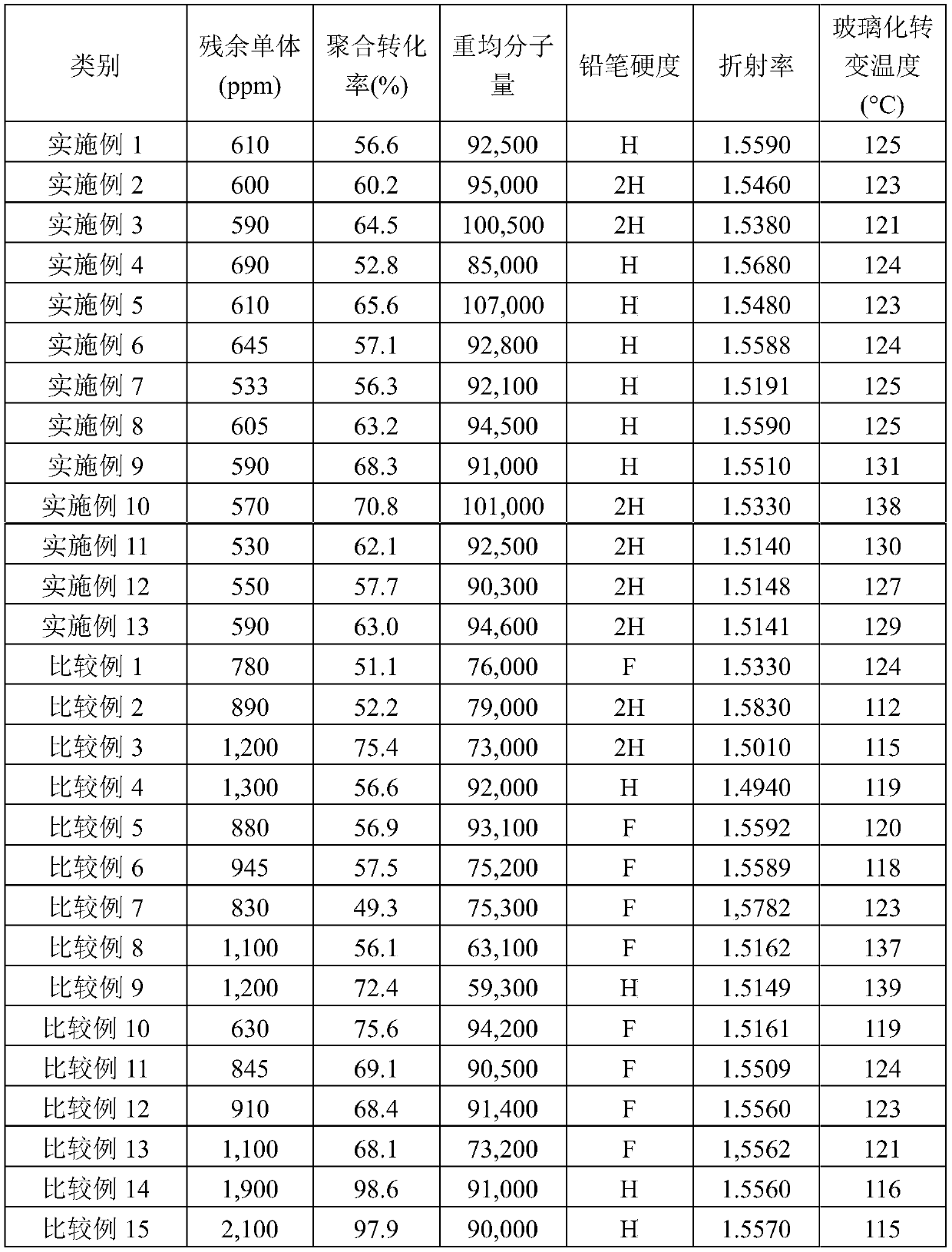

[0105] The physical properties of the copolymers of Examples and Comparative Examples were measured by the following methods, and the results are shown in Table 2 below.

[0106] 1) Residual monomer (ppm): The copolymer was dissolved in a chloroform solution and deposited in methanol, and the supernatant was used to measure by gel permeation chromatography.

[0107] 2) Polymerization conversion rate (%)=(the gross weight of the monomer mixture that adds initially-the gross weight of unreacted monomer mixture) / (the gross weight of the monomer mixture that adds initially) * 100

[0108] 3) Weight average molecular weight (g / mol): Measured as a relative value to a standard polystyrene (PS) sample by GPC (water breeze) using THF as an eluent.

[0109] 4) Pencil hardness: A pencil with a load of 0.5 kg was fixed at an angle of 45°, the surface of the extruded sample was scratched by hardness using the pencil, and the surface was checked with the naked eye for scratches, thereby mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com