Structural resin for high-speed offset ink and preparation method thereof

An offset printing ink and structural technology, which is applied in the structural resin of high-speed offset printing ink and its preparation field, can solve the problems of complex preparation process, low molecular weight, high softening point, etc., achieve clear steps, high softening point, and improve ink quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

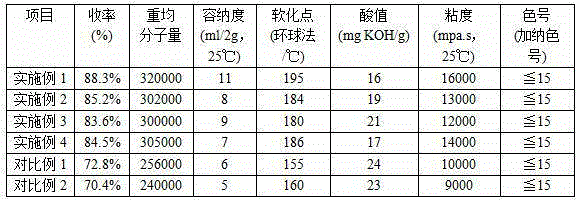

Examples

Embodiment 1

[0031] The steps of the preparation method of the structural resin used for high-speed offset printing ink in this embodiment are as follows:

[0032] The first step: put 100kg rosin into the reactor, feed N at 1500L / H 2 , heat up to 200°C, add 20kg of fumaric acid, keep the temperature at 200°C for 30 minutes, then raise the temperature to 230°C, add 100kg of pentaerythritol, then raise the temperature to 275°C at a uniform speed, keep the temperature until the acid value of the material in the kettle is 23mgKOH / g, The softening point is 110°C, the reaction time used is 9h, the temperature is lowered to 230°C, and the rosin derivative is obtained by filtering with a 100-mesh filter, which is set aside;

[0033] The second step: Put 100kg octylphenol, 1000kg paraformaldehyde and 0.3kg triethylamine into the reaction kettle, then raise the temperature to 95°C, keep warm and react until the Gardner viscosity of 80% isopropanol in the kettle is T-U. The reaction time is 2.5h, an...

Embodiment 2

[0036] The steps of the preparation method of the structural resin used for high-speed offset printing ink in this embodiment are as follows:

[0037] The first step: put 100kg rosin into the reactor, feed N at 1500L / H 2 , heat up to 190°C, add 10kg of fumaric acid, keep the temperature at 190°C for 40 minutes, then raise the temperature to 220°C, add 80kg of pentaerythritol, then raise the temperature to 265°C at a uniform speed, keep the temperature until the acid value of the material in the kettle is 28mgKOH / g, The softening point is 100°C, the reaction time used is 10h, the temperature is lowered to 210°C, and the rosin derivative is obtained by filtering with a 100-mesh filter, which is set aside;

[0038] The second step: put 100kg octylphenol, 80kg paraformaldehyde and 0.2kg triethylamine into the reaction kettle, then raise the temperature to 90°C, keep warm and react until the Gardner viscosity of 80% isopropanol in the kettle is T-U. The reaction time is 3h, and th...

Embodiment 3

[0041] The steps of the preparation method of the structural resin used for high-speed offset printing ink in this embodiment are as follows:

[0042] The first step: put 100kg rosin into the reactor, feed N at 1500L / H 2 , heat up to 210°C, add 30kg of fumaric acid, keep the temperature at 210°C for 20 minutes, then raise the temperature to 240°C, add 120kg of pentaerythritol, then raise the temperature to 285°C at a uniform speed, keep the temperature until the acid value of the material in the kettle is 22mgKOH / g, The softening point is 105°C, the reaction time used is 8h, the temperature is lowered to 230°C, and the rosin derivative is obtained by filtering with a 100-mesh filter, which is set aside;

[0043] Step 2: Put 100kg of octylphenol, 110kg of paraformaldehyde and 0.4kg into the reactor, then raise the temperature to 95°C, keep the heat until the Gardner viscosity of 80% isopropanol in the kettle is T-U, the reaction time used for 2 hours, lower the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com