A kind of rosin-modified phenolic resin for vacuum spraying high-grade paint and preparation method thereof

A phenolic resin, rosin modification technology, applied in rosin coatings and other directions, can solve problems such as insufficiency and low quality chain, and achieve the effects of preventing oxidation, high softening point, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

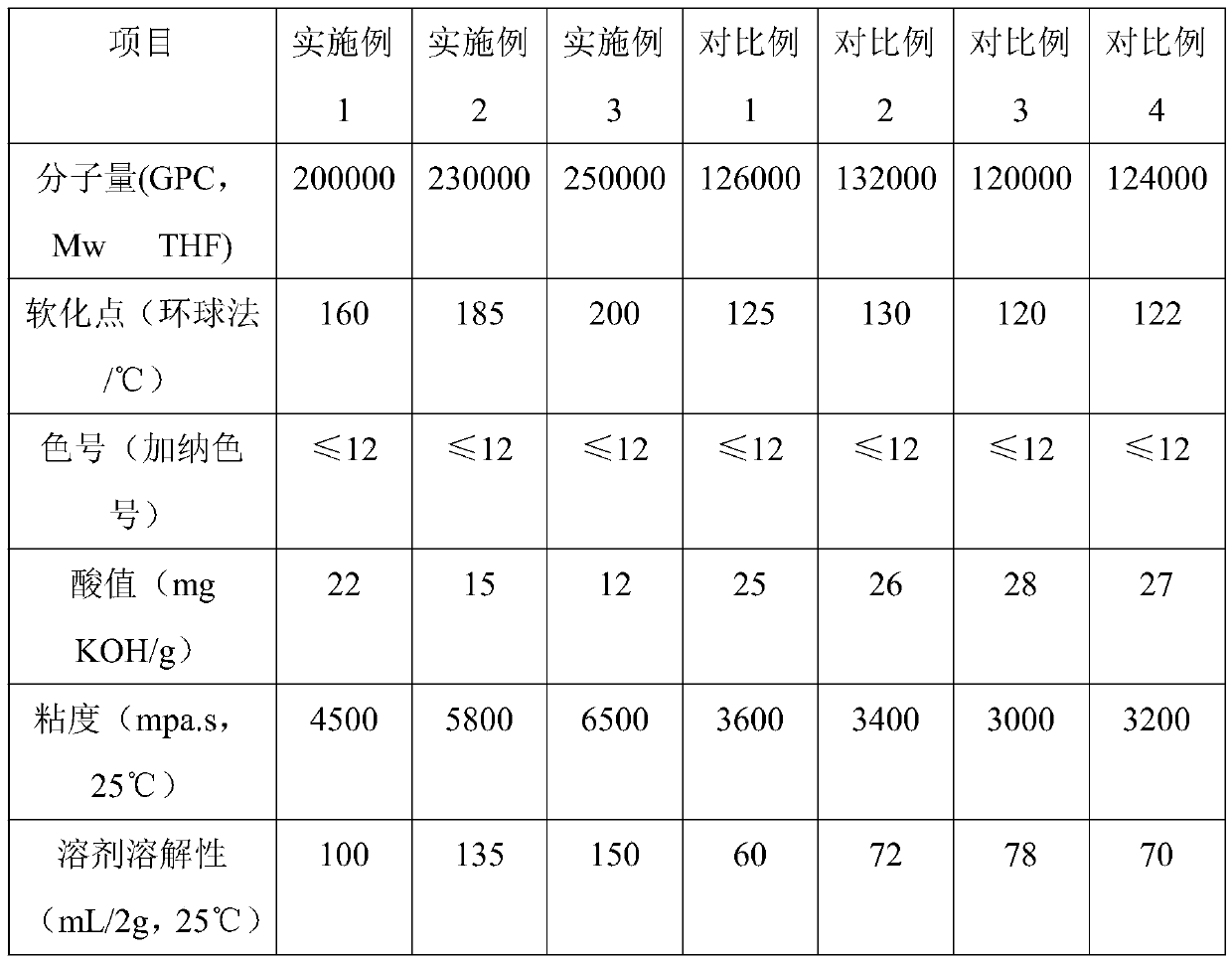

Examples

Embodiment 1

[0038] Embodiment 1, a kind of preparation method of rosin-modified phenolic resin for high-grade coating of vacuum spray paint

[0039] The preparation method of the rosin-modified phenolic resin for the vacuum spraying high-grade paint comprises the following steps:

[0040] S1 Put 100kg of p-tetraoctylphenol in a reaction vessel, heat until the p-tetraoctylphenol is completely melted, add 15kg of formaldehyde and 2kg of sodium hydroxide, stir, raise the temperature to 96°C, and keep it warm for 4 hours to obtain a phenolic resin;

[0041] S2 Put 100kg of rosin in a reaction vessel, heat to completely melt the rosin, stir, add 15kg of pentaerythritol and 0.4kg of a catalyst composed of titanium oxide and magnesium oxide in a mass ratio of 5:3, heat up to 268°C, and keep the temperature for 10 hours to obtain Rosin resin;

[0042] S3 put 30kg of the phenolic resin obtained in step S1 and 100kg of the rosin resin obtained in step S2 in a reaction container, add 0.39kg of magn...

Embodiment 2

[0043] Embodiment 2, a kind of preparation method of rosin modified phenolic resin for high-grade coating of vacuum spray paint

[0044] The preparation method of the rosin-modified phenolic resin for the vacuum spraying high-grade paint comprises the following steps:

[0045] S1 Put 100kg of p-tetraoctylphenol in a reaction vessel, heat until the p-tetraoctylphenol is completely melted, add 35kg of formaldehyde and 3kg of sodium hydroxide, stir, raise the temperature to 100°C, and keep it warm for 4 hours to obtain a phenolic resin;

[0046] S2 Put 100kg of rosin in a reaction vessel, heat to completely melt the rosin, stir, add 30kg of pentaerythritol and 0.8kg of a catalyst composed of titanium oxide and magnesium oxide at a mass ratio of 9:1, heat up to 272°C, and keep the temperature for 10 hours to obtain Rosin resin;

[0047] S3 put 70kg of the phenolic resin obtained in step S1 and the rosin resin obtained in 100kg of step S2 in a reaction container, add 1.02kg of mag...

Embodiment 3

[0048] Embodiment 3, a kind of preparation method of rosin-modified phenolic resin for vacuum spray paint high-grade paint

[0049] The preparation method of the rosin-modified phenolic resin for the vacuum spraying high-grade paint comprises the following steps:

[0050] S1 Put 100kg of p-tetraoctylphenol in a reaction vessel, heat until the p-tetraoctylphenol is completely melted, add 20kg of formaldehyde and 2.4kg of sodium hydroxide, stir, raise the temperature to 98°C, and keep it warm for 4 hours to obtain a phenolic resin;

[0051] S2 Put 100kg of rosin in a reaction vessel, heat to completely melt the rosin, stir, add 20kg of pentaerythritol and 0.6kg of a catalyst composed of titanium oxide and magnesium oxide in a mass ratio of 7:2, heat up to 270°C, and keep the temperature for 10 hours to obtain Rosin resin;

[0052] S3 put 40kg of the phenolic resin obtained in step S1 and the rosin resin obtained in 100kg of step S2 in a reaction container, add 0.56kg of magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com