A kind of structural resin for high-speed offset printing ink and its preparation method

An offset printing ink and structural technology, which is applied to the structural resin of high-speed offset printing ink and its preparation field, can solve the problems of complex preparation process, high softening point, low molecular weight, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

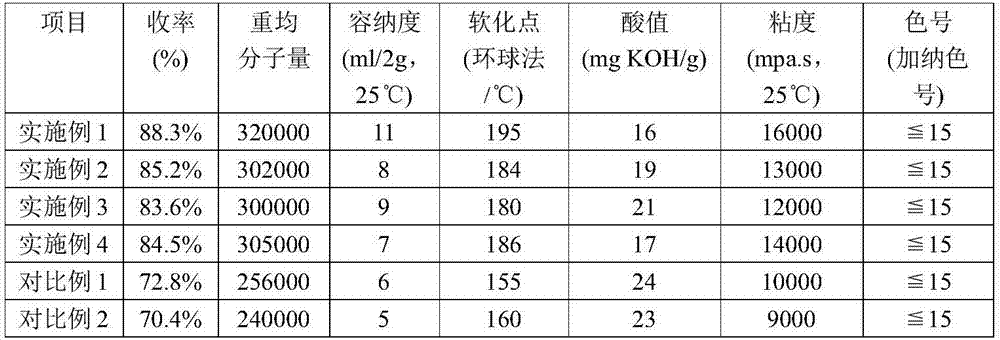

Examples

Embodiment 1

[0031] The steps of the preparation method of the structural resin used for high-speed offset printing ink in this embodiment are as follows:

[0032] The first step: put 100kg rosin into the reactor, feed N at 1500L / H 2 , raise the temperature to 200°C, add 20kg of fumaric acid, keep the temperature at 200°C for 30 minutes, then raise the temperature to 230°C, add 100kg of pentaerythritol, then raise the temperature to 275°C at a uniform speed, keep the temperature until the acid value of the material in the kettle is 23mg KOH / g , the softening point is 110°C, the reaction time used is 9h, the temperature is lowered to 230°C, and the rosin derivative is obtained by filtering with a 100-mesh filter, which is set aside;

[0033] The second step: put 100kg of octylphenol, 1000kg of paraformaldehyde and 0.3kg of triethylamine into the reaction kettle, then heat up to 95°C, and keep warm until the Gardner viscosity of 80% isopropanol in the kettle is T-U. The reaction time is 2.5...

Embodiment 2

[0036] The steps of the preparation method of the structural resin used for high-speed offset printing ink in this embodiment are as follows:

[0037] The first step: put 100kg rosin into the reactor, feed N at 1500L / H 2 , raise the temperature to 190°C, add 10kg of fumaric acid, keep the temperature at 190°C for 40 minutes, then raise the temperature to 220°C, add 80kg of pentaerythritol, then raise the temperature to 265°C at a uniform speed, keep the temperature until the acid value of the material in the kettle is 28mg KOH / g , the softening point is 100°C, the reaction time used is 10h, the temperature is lowered to 210°C, and the rosin derivative is obtained by filtering with a 100-mesh filter, which is set aside;

[0038] The second step: put 100kg octylphenol, 80kg paraformaldehyde and 0.2kg triethylamine into the reaction kettle, then raise the temperature to 90°C, and keep warm until the Gardner viscosity of 80% isopropanol in the kettle is T-U. The reaction time is ...

Embodiment 3

[0041] The steps of the preparation method of the structural resin used for high-speed offset printing ink in this embodiment are as follows:

[0042] The first step: put 100kg rosin into the reactor, feed N at 1500L / H 2 , raise the temperature to 210°C, add 30kg of fumaric acid, keep the temperature at 210°C for 20 minutes, then raise the temperature to 240°C, add 120kg of pentaerythritol, then raise the temperature to 285°C at a uniform speed, keep the temperature until the acid value of the material in the kettle is 22mg KOH / g , the softening point is 105°C, the reaction time used is 8h, the temperature is lowered to 230°C, and the rosin derivative is obtained by filtering with a 100-mesh filter, which is set aside;

[0043] The second step: put 100kg octylphenol, 110kg paraformaldehyde and 0.4kg into the reactor, then raise the temperature to 95°C, keep the heat until the Gardner viscosity of 80% isopropanol in the kettle is T-U, the reaction time used for 2 hours, lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com