Ring opening polymerization method of PBAT/PLA (poly(butylene adipate-co-terephthalate)/poly(lactic acid)) block copolymer

A block copolymer and ring-opening polymerization technology, applied in the field of biodegradable materials, can solve the problems of low weight average molecular weight and low yield, and achieve the effect of high weight average molecular weight and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

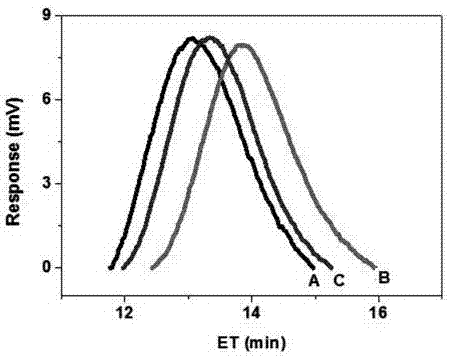

Image

Examples

Embodiment 1

[0028] Put 146g of adipic acid, 194g of dimethyl terephthalate, and 216g of 1,4-butanediol into the reaction kettle, protect it with nitrogen, and heat it to 140°C. After the materials in the reaction kettle are completely melted, add tetrabutyl titanate Esters 5.56mg. Vacuumize to 0.06Mpa, react for 2h, then gradually increase the temperature to 230°C within 1h, control the vacuum degree at 1000Pa, continue to react for 5h, and obtain the prepolymer PBAT. Afterwards, 5.8 g of ethylene glycol was added for direct polycondensation reaction, and the vacuum degree was controlled at 1000 Pa. After 0.1 h of reaction, the material was discharged to obtain PBAT with hydroxyl groups at both ends, and the weight-average molecular weight was 60,000.

[0029] 60 g of PBAT with hydroxyl groups at both ends and 60 g of L-lactide were put into the reactor. The temperature is controlled at 160°C. After the material in the kettle is completely melted, 6 mg of stannous octoate is added, and t...

Embodiment 2

[0031] Put 146g of adipic acid, 97g of dimethyl terephthalate, and 135g of 1,4-butanediol into the reaction kettle, protect it with nitrogen, and heat it to 160°C. After the materials in the reaction kettle are completely melted, add tetra-titanate Butyl ester 37.8 mg. Vacuumize to 0.02Mpa, react for 2h, then gradually increase the temperature to 220°C within 2h, control the vacuum degree at 500Pa, and continue to react for 4h. The prepolymer PBAT was obtained, and then 4.5 g of hexanediol was added to carry out direct polycondensation reaction. The vacuum degree was controlled at 5 Pa. After 2 hours of reaction, the material was discharged to obtain PBAT with hydroxyl groups at both ends, and the weight average molecular weight was 100,000.

[0032] 60 g of PBAT with hydroxyl groups at both ends and 60 g of L-lactide were put into the reactor. The temperature is controlled at 200°C. After the material in the kettle is completely melted, 60 mg of stannous octoate is added, an...

Embodiment 3

[0034] Put 73g of adipic acid, 194g of dimethyl terephthalate, and 135g of 1,4-butanediol into the reaction kettle, protect it with nitrogen, and heat it to 150°C. After the materials in the reaction kettle are completely melted, add tetratitanate Butyl ester 2.01 g. Vacuumize to 0.04Mpa, react for 2h, then gradually increase the temperature to 210°C within 1h, control the vacuum degree at 800Pa, and continue to react for 1h. The prepolymer PBAT was obtained, and then 4.3 g of diethylene glycol was added to carry out direct polycondensation reaction. The vacuum degree was controlled at 2000 Pa. After 1 hour of reaction, the PBAT with hydroxyl groups at both ends was obtained, and the weight average molecular weight was 10000.

[0035] 60 g of PBAT with hydroxyl groups at both ends and 60 g of L-lactide were put into the reactor. The temperature is controlled at 120°C. After the material in the kettle is completely melted, 30 mg of stannous octoate is added, and the vacuum deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com