Catalytic system for preparation of wide-distribution polyolefin, and application of catalytic system

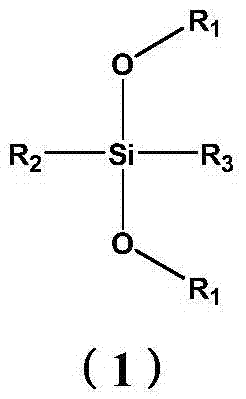

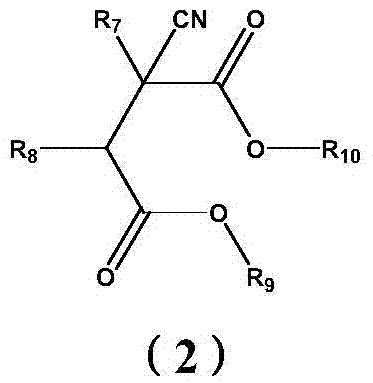

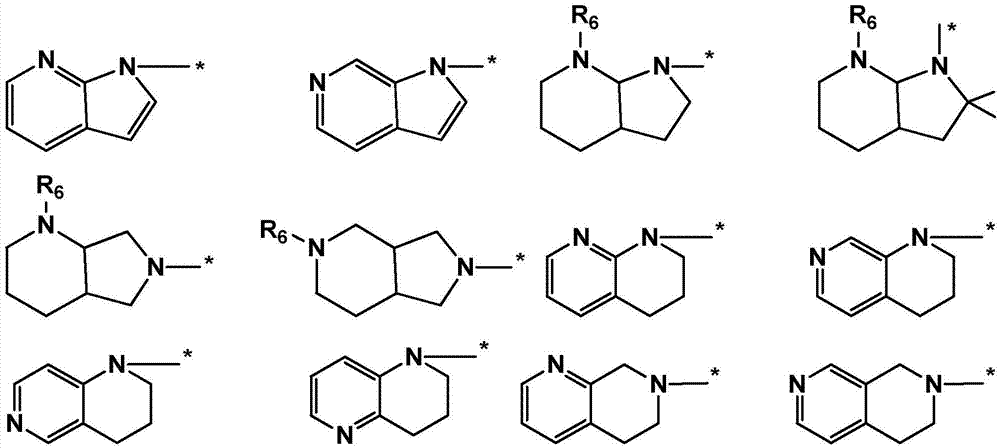

A catalytic system and polyolefin technology, which are applied in the field of catalytic systems for olefin polymerization and the preparation of catalytic systems for wide-distribution polyolefins, can solve the problems of low catalytic activity, narrow relative molecular mass distribution of polymers, and difficult synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The magnesium halide alcoholate of the general formula (3) in the present invention can be prepared by methods known in the industry, such as spray drying, spray cooling, high-pressure extrusion or high-speed stirring. The specific preparation method may include the following steps: in a closed container, the optional inert medium is heated to 100 ° C ~ 140 ° C, adding magnesium halide MgX 2 , Alcohol R 11 OH, after fully reacting, it forms a mixture containing molten magnesium halide alcoholate, which is quenched and formed by low-temperature inert medium after high shear, to form spherical magnesium halide alcoholate pellets. High-shear action can adopt conventional methods, such as high-speed stirring method (such as Chinese patent CN1330086), spraying method (such as US6020279) and high gravity rotating bed (such as CN1580136A) and emulsifier (CN1463990A) etc. The cooling medium can be an inert hydrocarbon solvent with a lower boiling point, such as pentane, hexane...

Embodiment 1

[0150] (1) Preparation of spherical catalyst solid components

[0151] Prepare spherical magnesium chloride alcoholate MgX with reference to the embodiment 1 method in Chinese patent CN1091748A 2 ·(R 11 Oh) m , where X=C1, R 11 =C 2 h 5 , m=2.4.

[0152] In a 300ml double-layer glass reaction bottle, add 100ml of titanium tetrachloride, cool to -20°C, add 8 grams of the above-mentioned spherical magnesium chloride alcoholate, heat up to 100°C, and add according to the Chinese invention patent application number during the heating process. 2,3-diisopropyl-2-cyanodiethyl succinate (ID1) 2.5mmol prepared by the method described in the patent application description of 200910077779.6, diisobutyl phthalate (ID2) 2.5mmol filter Remove liquid, wash twice with titanium tetrachloride, wash four times with hexane, and obtain spherical catalyst solid component after vacuum drying.

[0153] (2) Propylene polymerization

[0154] The 5L autoclave is heated and evacuated, air and wat...

Embodiment 2

[0156] The internal electron donor is 2,3-diisopropyl-2-cyanosuccinate (ID1) 4mmol, diisobutyl phthalate (ID2) 1mmol, and the external electron donor is diisopropyl Basepiperazine dimethoxysilane (ED1), the amount of hydrogenation is 300mmol, and others are the same as in Example 1. All test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com