Fluorine-based surface treating agent for vapor deposition and article finished with the surface treating agent by vapor deposition

A surface treatment agent and vapor deposition technology, applied in the input/output process of data processing, thin material processing, electrical digital data processing, etc., can solve the problems of lack of durability, easy aggregation of non-fluorine groups, etc., and achieve good durability staining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11 and comparative example 1-9

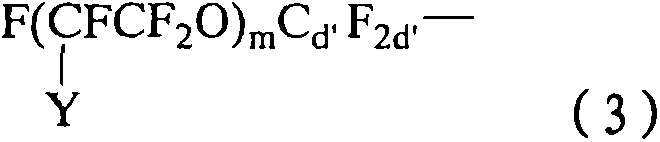

[0166] The following 5 specific compounds were prepared as examples of silanes modified with fluorine-containing oxyalkylene group polymers.

[0167] Compound 1

[0168]

[0169] (weight average molecular weight 4,600)

[0170] Compound 2

[0171] HF 2 C(OC 2 f 4 ) p (OCF 2 ) q -OCF 2 CH 2 OC 3 h 6 Si(OCH 3 ) 3

[0172] Weight average molecular weight is 4,400)

[0173] Compound 3

[0174] f 3 C(OC 2 f 4 ) p (OCF 2 ) q -OCF 2 CH 2 OC 3 h 6 Si(OCH 3 ) 3

[0175] Weight average molecular weight is 4,400)

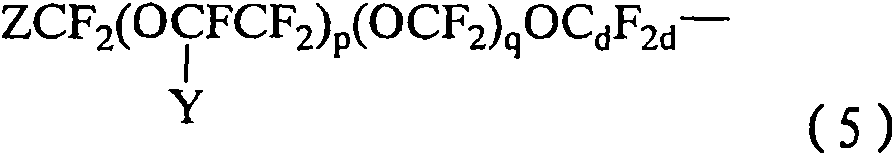

[0176] Compound 4

[0177] (CH 3 O) 3 SiC 3 h 6 OCH 2 -CF 2 (OC 2 f 4 ) p′ (OCF 2 ) q′ OCF 2 -CH 2 OC 3 h 6 Si(OCH 3 ) 3

[0178] Weight average molecular weight is 4,600)

[0179] Compound 5

[0180] (CH 3 O) 3 SiC 3 h 6 OCH 2 -CF 2 (OC 2 f 4 ) p′ (OCF 2 ) q′ OCF 2 -CH 2 OC 3 h 6 Si(OCH 3 ) 3

[0181] Weight average molecular weight 2,600)

[0182] The polymer containing fluorinated oxyalkylene gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com