Rosin modified phenolic resin for vacuum paint spraying high-grade coating and preparation method of rosin modified phenolic resin

A technology for modifying phenolic resin and rosin, which is applied in rosin coatings and coatings. It can solve the problems of low-end quality chain and unsatisfactory conditions, and achieve the effects of high softening point, anti-oxidation and high viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

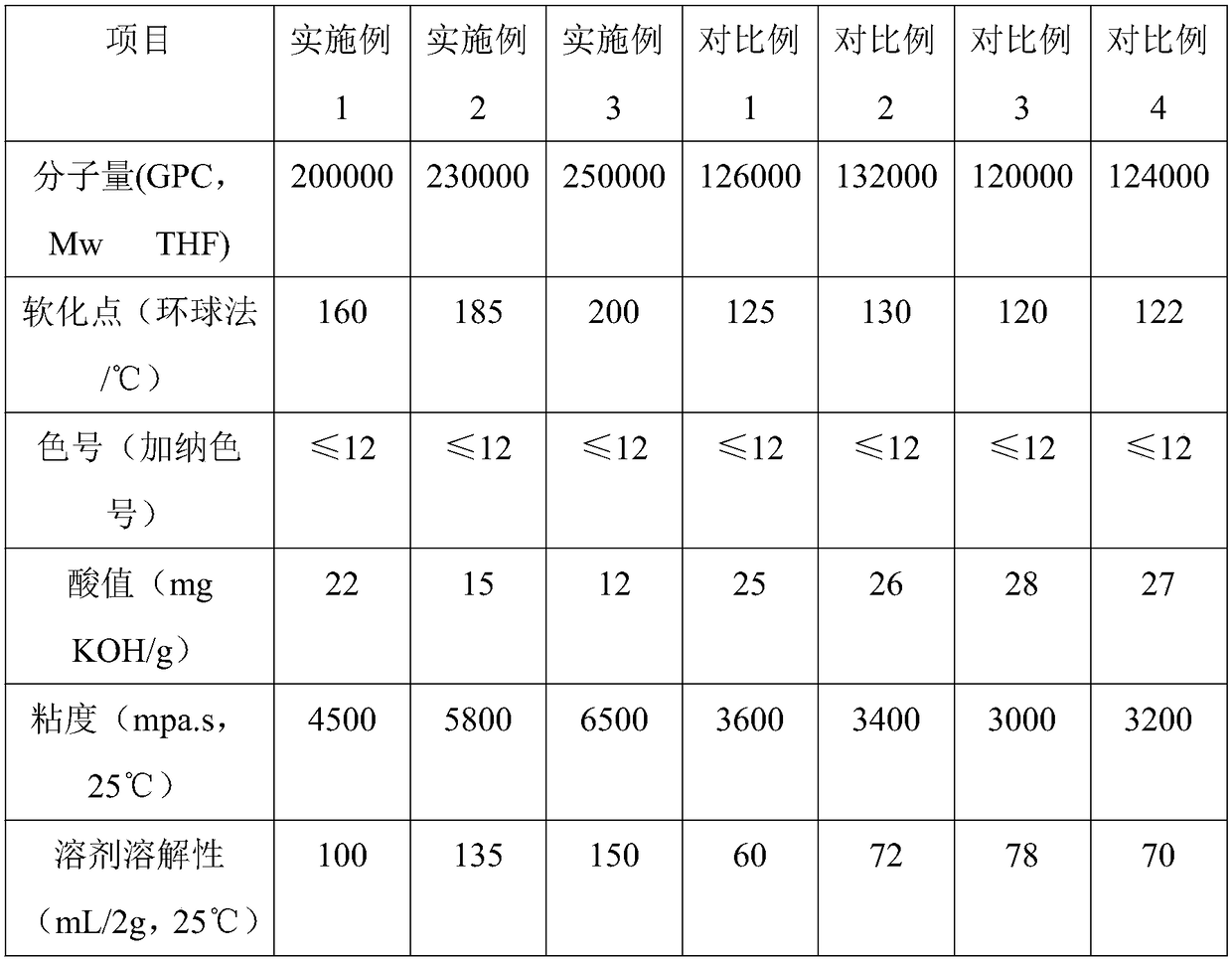

Examples

Embodiment 1

[0038] Embodiment 1, a kind of preparation method of rosin-modified phenolic resin for high-grade coating of vacuum spray paint

[0039] The preparation method of the rosin-modified phenolic resin for the vacuum spraying high-grade paint comprises the following steps:

[0040] S1 Put 100kg of p-tetraoctylphenol in a reaction vessel, heat until the p-tetraoctylphenol is completely melted, add 15kg of formaldehyde and 2kg of sodium hydroxide, stir, raise the temperature to 96°C, and keep it warm for 4 hours to obtain a phenolic resin;

[0041] S2 Put 100kg of rosin in a reaction vessel, heat to completely melt the rosin, stir, add 15kg of pentaerythritol and 0.4kg of a catalyst composed of titanium oxide and magnesium oxide in a mass ratio of 5:3, heat up to 268°C, and keep the temperature for 10 hours to obtain Rosin resin;

[0042] S3 put 30kg of the phenolic resin obtained in step S1 and 100kg of the rosin resin obtained in step S2 in a reaction container, add 0.39kg of magn...

Embodiment 2

[0043] Embodiment 2, a kind of preparation method of rosin modified phenolic resin for high-grade coating of vacuum spray paint

[0044] The preparation method of the rosin-modified phenolic resin for the vacuum spraying high-grade paint comprises the following steps:

[0045] S1 Put 100kg of p-tetraoctylphenol in a reaction vessel, heat until the p-tetraoctylphenol is completely melted, add 35kg of formaldehyde and 3kg of sodium hydroxide, stir, raise the temperature to 100°C, and keep it warm for 4 hours to obtain a phenolic resin;

[0046] S2 Put 100kg of rosin in a reaction vessel, heat to completely melt the rosin, stir, add 30kg of pentaerythritol and 0.8kg of a catalyst composed of titanium oxide and magnesium oxide at a mass ratio of 9:1, heat up to 272°C, and keep the temperature for 10 hours to obtain Rosin resin;

[0047] S3 put 70kg of the phenolic resin obtained in step S1 and the rosin resin obtained in 100kg of step S2 in a reaction container, add 1.02kg of mag...

Embodiment 3

[0048] Embodiment 3, a kind of preparation method of rosin-modified phenolic resin for vacuum spray paint high-grade paint

[0049] The preparation method of the rosin-modified phenolic resin for the vacuum spraying high-grade paint comprises the following steps:

[0050] S1 Put 100kg of p-tetraoctylphenol in a reaction vessel, heat until the p-tetraoctylphenol is completely melted, add 20kg of formaldehyde and 2.4kg of sodium hydroxide, stir, raise the temperature to 98°C, and keep it warm for 4 hours to obtain a phenolic resin;

[0051] S2 Put 100kg of rosin in a reaction vessel, heat to completely melt the rosin, stir, add 20kg of pentaerythritol and 0.6kg of a catalyst composed of titanium oxide and magnesium oxide in a mass ratio of 7:2, heat up to 270°C, and keep the temperature for 10 hours to obtain Rosin resin;

[0052] S3 put 40kg of the phenolic resin obtained in step S1 and the rosin resin obtained in 100kg of step S2 in a reaction container, add 0.56kg of magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com