Catalyst component and catalyst for olefin polymerization

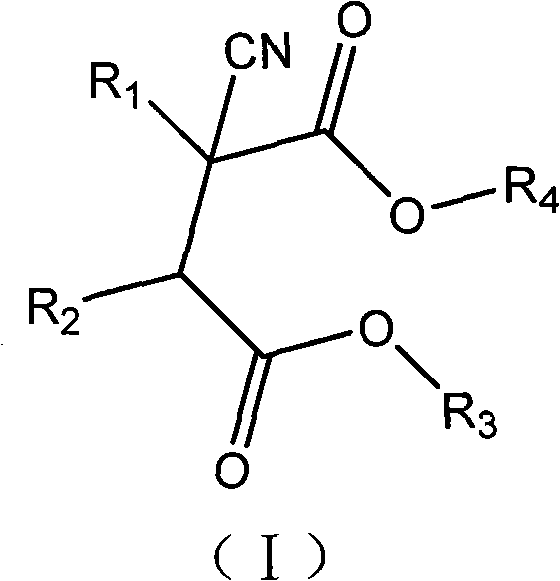

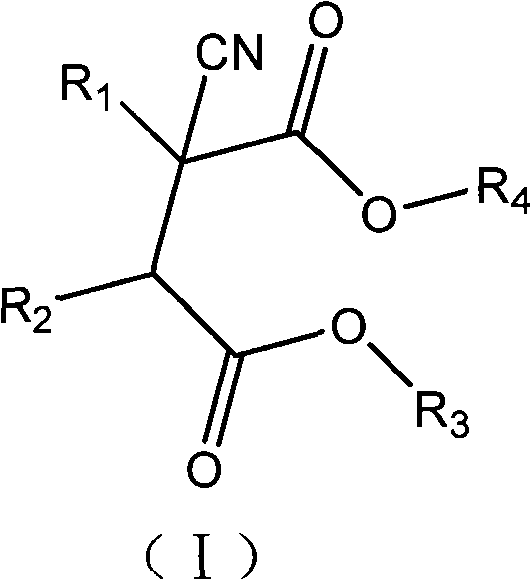

A technology for olefin polymerization and solid catalyst, which is applied in the field of catalyst components and catalysts, and can solve the problems of difficult industrial application of synthesis processes, low catalyst activity, and low catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Preparation of catalyst solid components

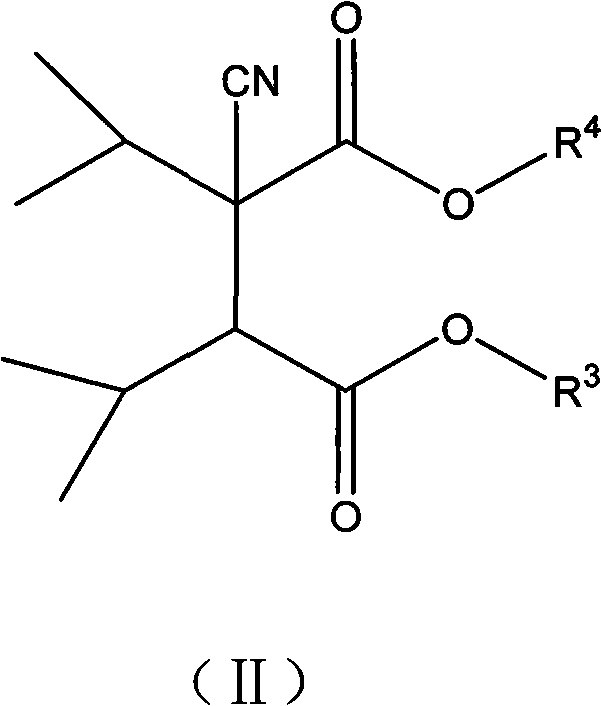

[0069] In the high-purity N 2 In the fully replaced glass bottle, add 5.0 g of anhydrous MgCl successively 2 , 140ml of toluene, 8.0ml of epichlorohydrin, and 10.0ml of tributyl phosphate are completely dissolved at 60°C, and 1.4 grams of phthalic anhydride are added respectively, as described in the patent application specification of China Invention Patent Application No. 200910077779.6 Prepare 5mmol of 2,3-diisopropyl-2-cyanodiethyl succinate, cool the solution to -25°C, then drop 50ml of titanium tetrachloride into it, at -25°C Stir for half an hour, add 3.0 g of silica gel (Davison XPO2485, dry at 600°C for 4 hours before using the silica gel), and then slowly raise the temperature to 90°C to obtain a solid precipitate. After filtering, add 70ml of toluene, wash twice, and separate solid. Then use 60ml of toluene and 40ml of titanium tetrachloride to heat up to 100°C for two hours, filter and wash with toluene and h...

Embodiment 2

[0083] (1) The preparation of the solid component of the catalyst is the same as in Example 1, except that 2.5 mmol of diisobutyl phthalate and 2.5 mmol of 2,3-diisopropyl-2-cyanodiethyl succinate are added successively. mmol, instead of diethyl 2,3-diisopropyl-2-cyanosuccinate (5 mmol) added alone.

[0084] (2) The propylene polymerization method is the same as that of Example 1, and the test results are shown in Table 1.

[0085] The performance of table 1 catalyst

[0086]

[0087] It can be seen from the data in the table that the performance of the catalyst is excellent, not only the activity for propylene polymerization is equivalent to that of the existing catalyst containing internal electron donors of diisobutyl phthalate, but also the polymer has good isotacticity and high weight-average molecular weight , a wider molecular weight distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com