Cigarette quality detection system and detection method

A detection system and cigarette technology, which are applied in the fields of tobacco, cigarette manufacturing, and application, can solve the problems of broken hollow tubes, reversed splicing of hollow tubes and cut tobacco segments, and large splicing gaps, so as to improve the product qualification rate and improve the The effect of cigarette quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

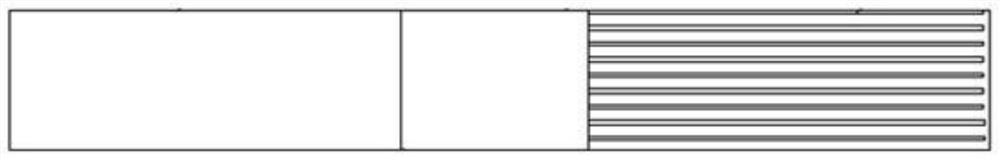

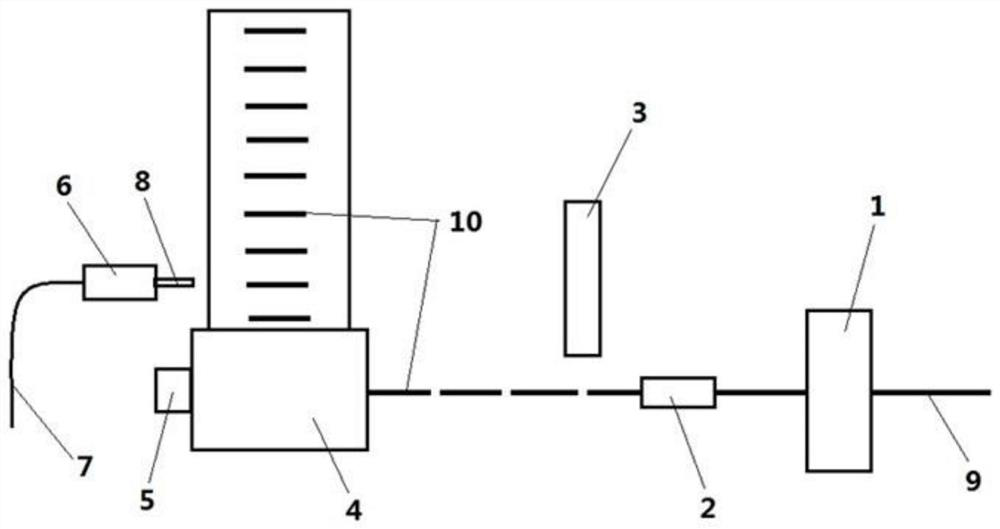

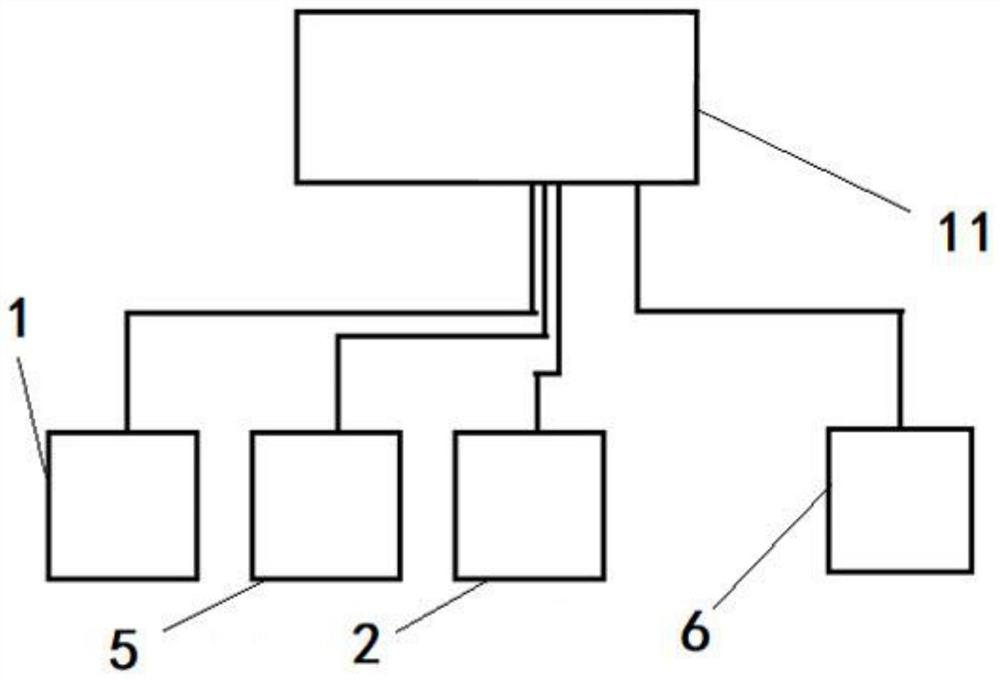

[0043] combined with figure 2 and image 3 As shown, a cigarette quality inspection system includes a microwave scanner 1, an encoder 5, a PLC controller 11, an optical fiber detector 2 and a solenoid valve 6, a microwave scanner 1, an encoder 5, an optical fiber detector 2 and a solenoid valve 6 is connected to the PLC controller 11, and also includes a cigarette direction adjusting device 4 and a riving knife device 3.

[0044] The microwave scanner 1 is installed on the tobacco rod forming assembly. When the spliced tobacco rods pass through the microwave scanner 1, the microwave scanner 1 continuously scans the tobacco rods 9, detects the density of the tobacco rods with microwaves, and forms voltage signals of different amplitudes. , and send it to the PLC controller 11, and the PLC controller 11 judges the tobacco rod material according to the different amplitudes of the voltage signal;

[0045] When the cigarette rod 9 passes through the optical fiber detector 2, t...

Embodiment 2

[0049] A cigarette quality detection method, comprising:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com